Intelligent accumulation and tearing detection device for belt conveyors

A belt conveyor and intelligent detection technology, applied in the direction of conveyor control devices, transportation and packaging, conveyors, etc., to achieve the effects of simple structure, reduced workload, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

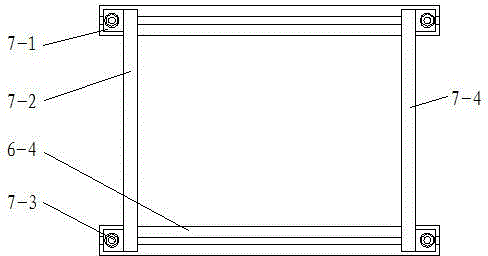

[0019] Such as figure 1 As shown, a lower feed bin 5 is installed between the front belt conveyor 8 tail and the head of the rear belt conveyor 6, and a high-definition camera 4 is installed above the lower feed bin. The monitoring range of the high-definition camera is the belt conveyor blanking place and the lower On the top of the silo, the high-definition camera is connected to the computer 1 through the intelligent optical transceiver 3 and the intelligent video analyzer 2, and an infrared detection light is installed on the frame 6-3 between the upper and lower belts 6-1 in the belt conveyor 6 below the lower silo. Curtain 7, the infrared detection light curtain is connected with computer through electric control device 9, and warning device is installed in computer. The electrical control device controls the rotation and stop of the belt conveyor.

[0020] Such as Figure 5 As shown, a filter 4-1 is installed on the lens of the high-definition camera 4, and an infrare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com