Automatic ultrasonic nondestructive test apparatus for dies and control system and test control method thereof

A non-destructive testing, ultrasonic technology, applied in general control systems, control/regulation systems, program control in sequence/logic controllers, etc., can solve the problems of incomplete mold testing, low automation, low testing efficiency, etc. The detection speed is fast, the display is intuitive, and the detection speed is stable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

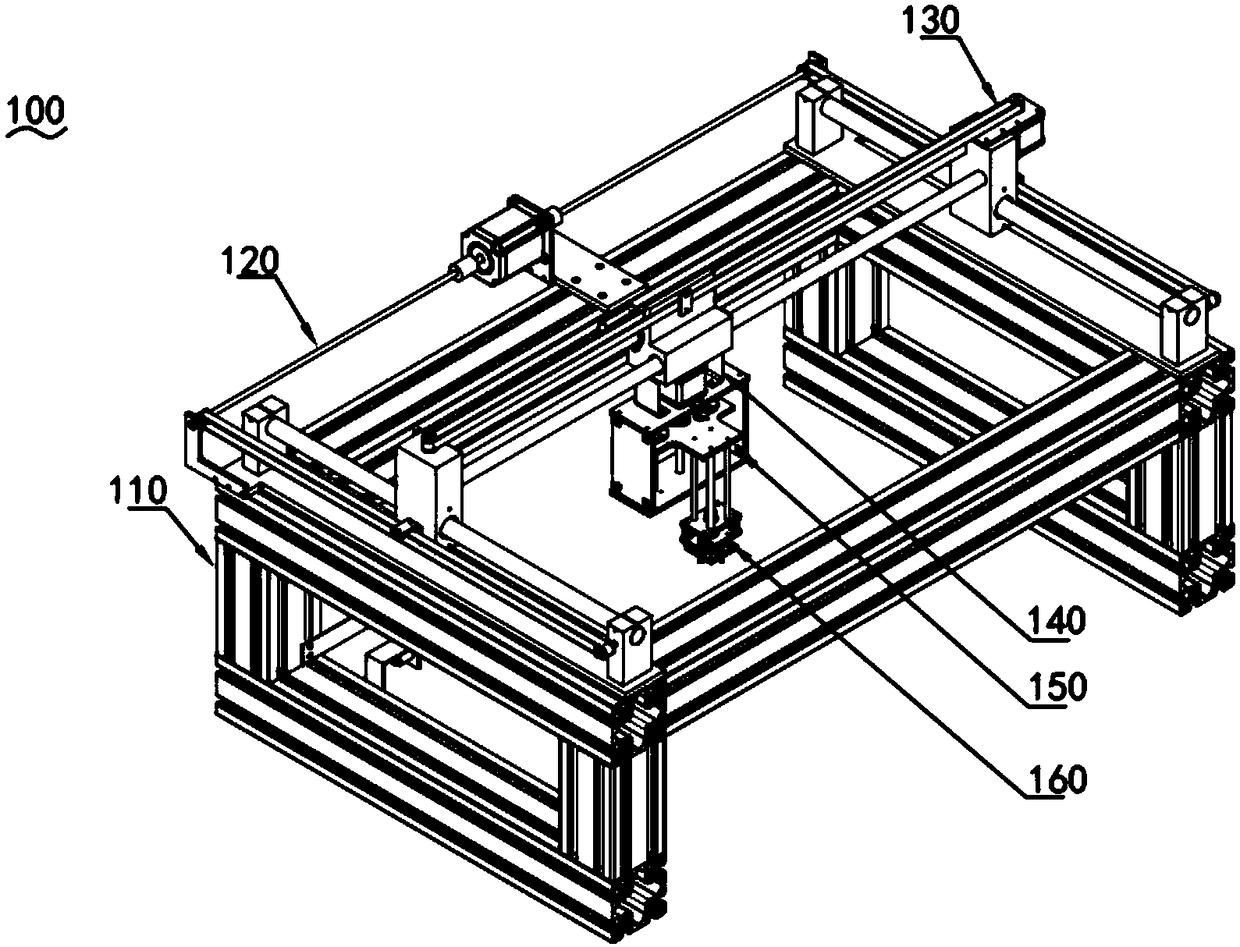

[0037] Such as figure 1 Shown is a perspective view of the present invention.

[0038] The automatic ultrasonic mold non-destructive testing equipment 100 is provided with a frame 110, an X-axis transmission device 120 arranged on the upper part of the frame 110, a Y-axis transmission device 130 arranged on the X-axis transmission device 120, and a Y-axis transmission device 130 arranged on the Y-axis transmission device 130 The detection mechanical arm; the detection mechanical arm includes a connection base 140 connected to the Y-axis transmission device 130, a Z-axis transmission device 150 installed on the connection base 140, and a detection device 160 fixedly connected to the Z-axis transmission device 150, the The detection device 160 includes a connecting rod 161 fixedly connected to the Z-axis transmission device 150, a fixed plate 162 fixedly connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com