Pretreatment device for zinc plating of steel wire

A pretreatment device, a technology for steel wire galvanizing, applied in mixers with rotary stirring devices, transportation and packaging, hot dip plating processes, etc. and other problems to achieve the effect of reducing temperature difference and increasing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

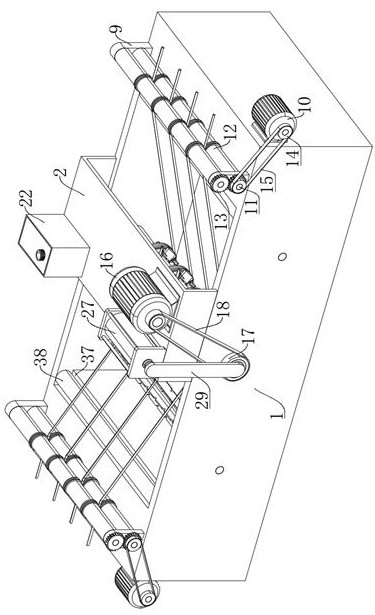

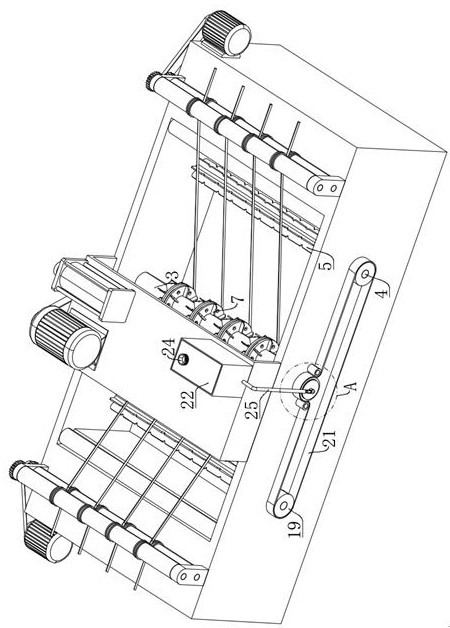

[0037] As an embodiment of the present invention, the wire guide mechanism includes two mounting blocks 9 and a first motor 10 , the mounting blocks 9 are fixedly connected to the top surface of the processing tank 1 , and two first motors are rotatably connected between the mounting blocks 9 . The two rotating shafts 11 and the second rotating shaft 11 are fixedly connected with a transmission roller 12, and the second rotating shaft 11 is fixedly connected with a gear 13, and the gears 13 are meshed with each other. The first motor 10 is fixedly installed on the side of the processing tank 1, wherein A first transmission wheel 14 is fixedly connected to one end of a second rotating shaft 11 and the output shaft of the first motor 10, and the first transmission wheel 14 is driven by a first transmission belt 15; during operation, the first motor 10 drives The first transmission wheel 14 on the output shaft rotates, and the first transmission belt 15 drives one of the second rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com