Anti-corrosion flexible epoxy composite coiled material as well as preparation method and application thereof

A flexible epoxy and composite roll technology, which is applied in chemical instruments and methods, building insulation materials, synthetic resin layered products, etc., can solve problems such as poor scratch resistance, insufficient flexibility, and intolerance to bending. Achieve the effects of reducing process energy consumption, good flexibility, economical and environmental protection in the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

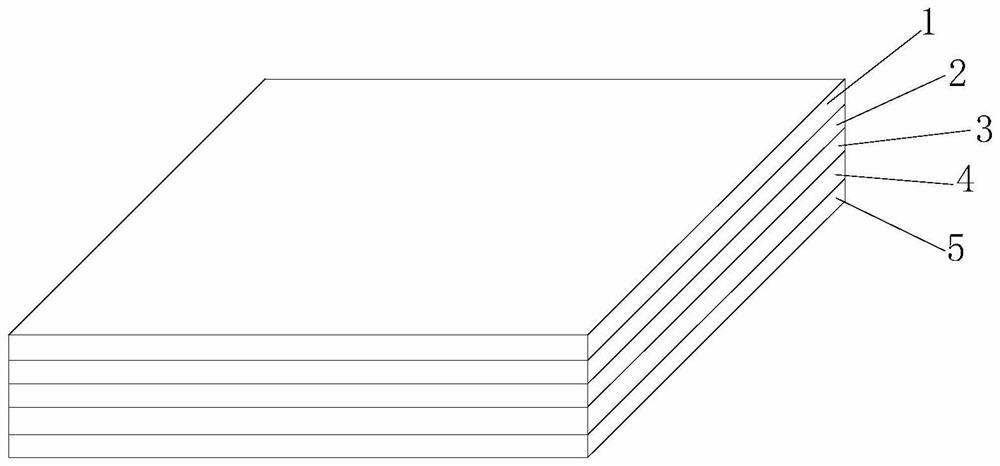

[0057] The flexible epoxy composite coil provided in this embodiment, such as figure 1 As shown, it includes a first resin layer 1 , a first reinforcing layer 2 , a second resin layer 3 , a second reinforcing layer 4 and a third resin layer 5 that are stacked in sequence from top to bottom.

[0058] In this example, the first reinforcing layer 2 is a glass fiber mesh cloth layer, and a glass fiber mesh cloth with a mesh size of 3×3 mm is selected, and the weight per square is 100g; the second reinforcing layer 4 is a flame-retardant polyester fiber cloth layer, with a thickness of is 1.2mm.

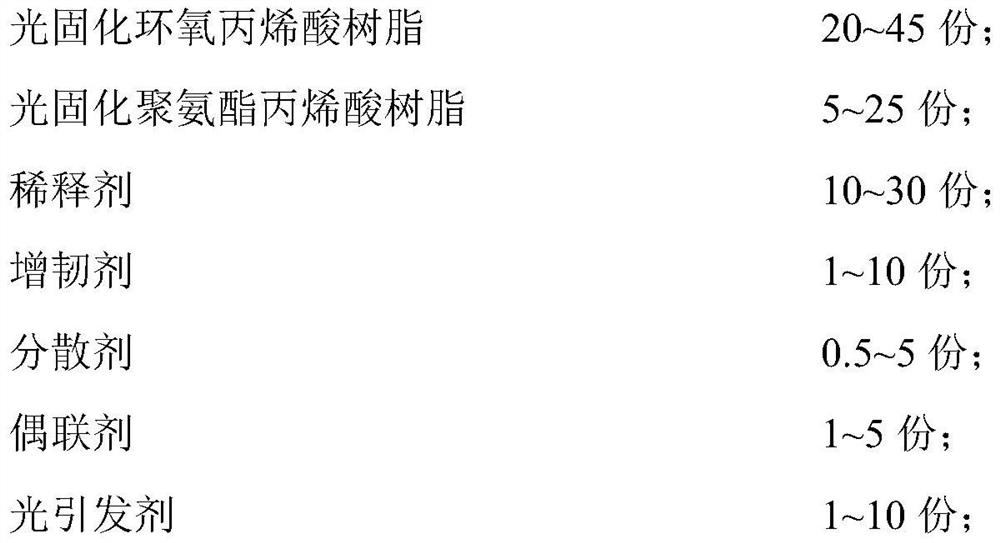

[0059] The raw material formula of the first resin layer 1 is as follows: 40 parts of light-cured epoxy acrylic resin L-6136, 10 parts of light-cured urethane acrylic resin FSP38569, 5 parts of toughening agent o-phthalic flexible unsaturated resin, 20 parts of thinner (two Propylene glycol diacrylate and glycidyl methacrylate compound diluent in mass ratio of 5:1), 3 parts of dispersant...

Embodiment 2

[0067] The flexible epoxy composite coil provided in this embodiment is different from Embodiment 1 in that the raw materials of the first resin layer 1 , the raw materials of the second resin layer 3 , the raw materials of the third resin layer 5 and the raw materials of the first reinforcing layer 2 Different materials:

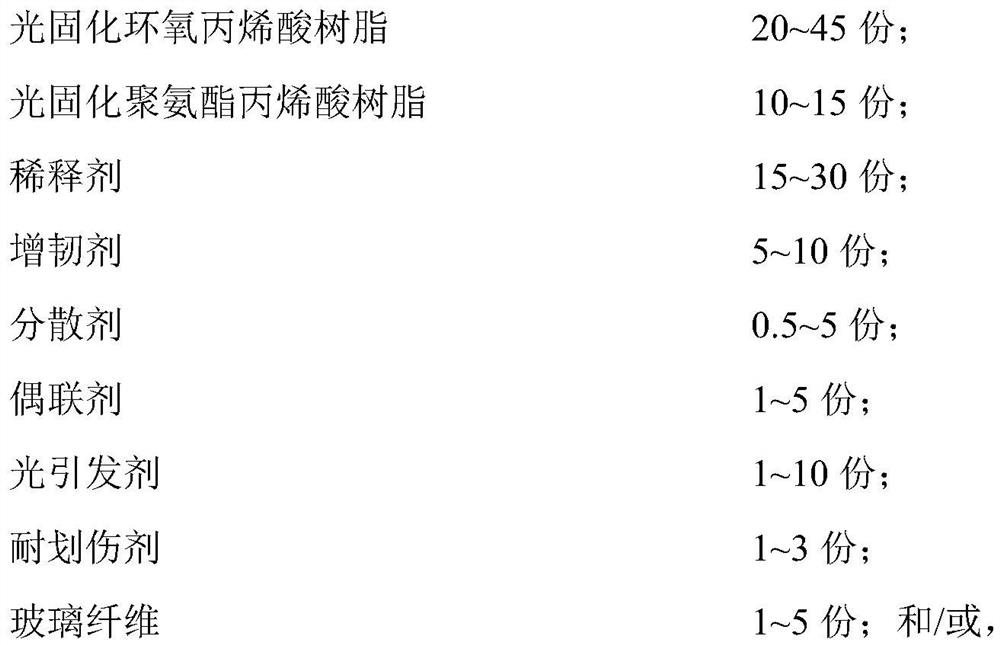

[0068]In this example, the raw material formula of the first resin layer 1 is as follows: 20 parts of light-cured epoxy acrylic resin L-6135, 15 parts of light-cured urethane acrylic resin Unicryl R7496, 5 parts of toughener o-phthalic flexible unsaturated resin, 15 parts of parts of diluent (a compound diluent of acrylate glycerol derivatives and 1,2-epoxy-5-hexene in a mass ratio of 2:1), 3 parts of dispersant polyether-modified siloxane, 1 Parts of scratch-resistant agent nano-silica, 2 parts of chopped glass fiber with a length of 3mm, 3 parts of coupling agent KH-570 and 3 parts of photoinitiator 1173.

[0069] In this example, the raw material formul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com