3D printing workshop based on additive manufacturing industry internet platform

An industrial Internet and 3D printing technology, applied in the field of 3D printing workshop, can solve problems such as labor cost increase, and achieve the effect of saving manpower, enhancing economic benefits and improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below with reference to the accompanying drawings.

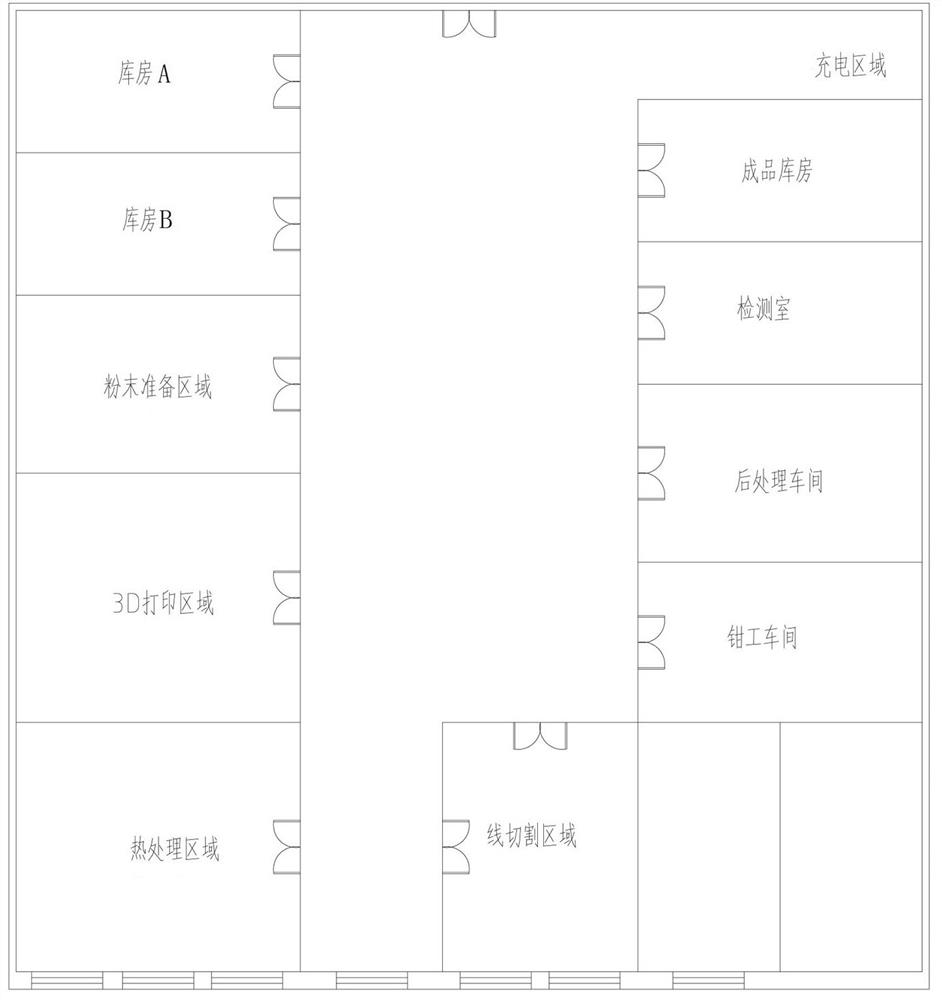

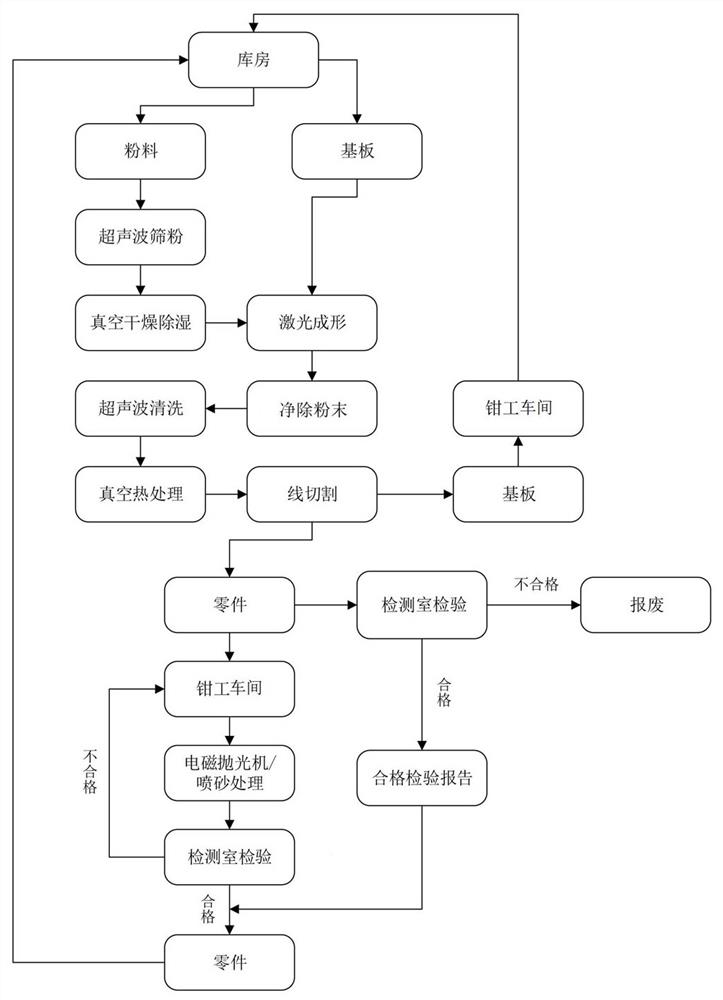

[0017] 3D printing workshop based on the additive manufacturing industrial Internet platform, including warehouse A, warehouse B, powder preparation area, 3D printing area, heat treatment area, wire cutting area, fitter workshop, post-processing workshop, testing room, finished product warehouse, AGV car and In the charging area, the base plate, scraper and accessories are stored in the warehouse A, and the powder is stored in the warehouse B. The AGV trolley sends the powder from the warehouse B to the powder preparation area, and the powder is sieved by ultrasonic waves in the powder preparation area. The AGV trolley transports the processed powder and substrate to the 3D printing area, manually removes the powder and substrate, and uses the 3D printing equipment in the 3D printing area to produce parts; the AGV trolley The parts are transported to the heat treatment a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com