Automatic assembling and testing production line for server mainboard

A technology of automatic assembly and server, which is used in assembly machines, transportation and packaging, and detection of faulty computer hardware.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

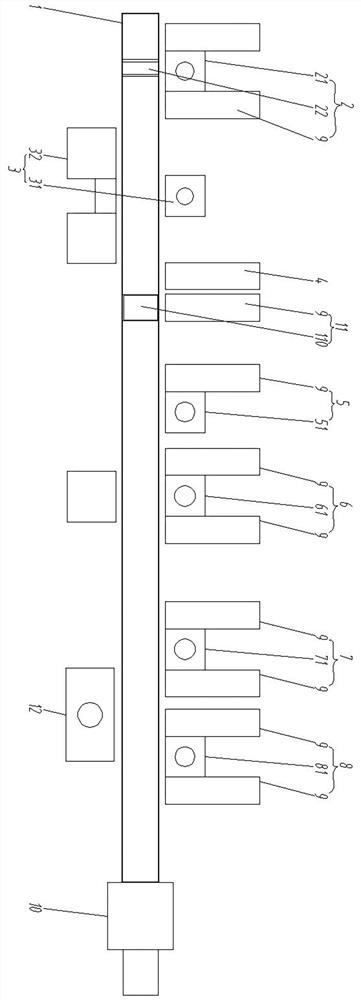

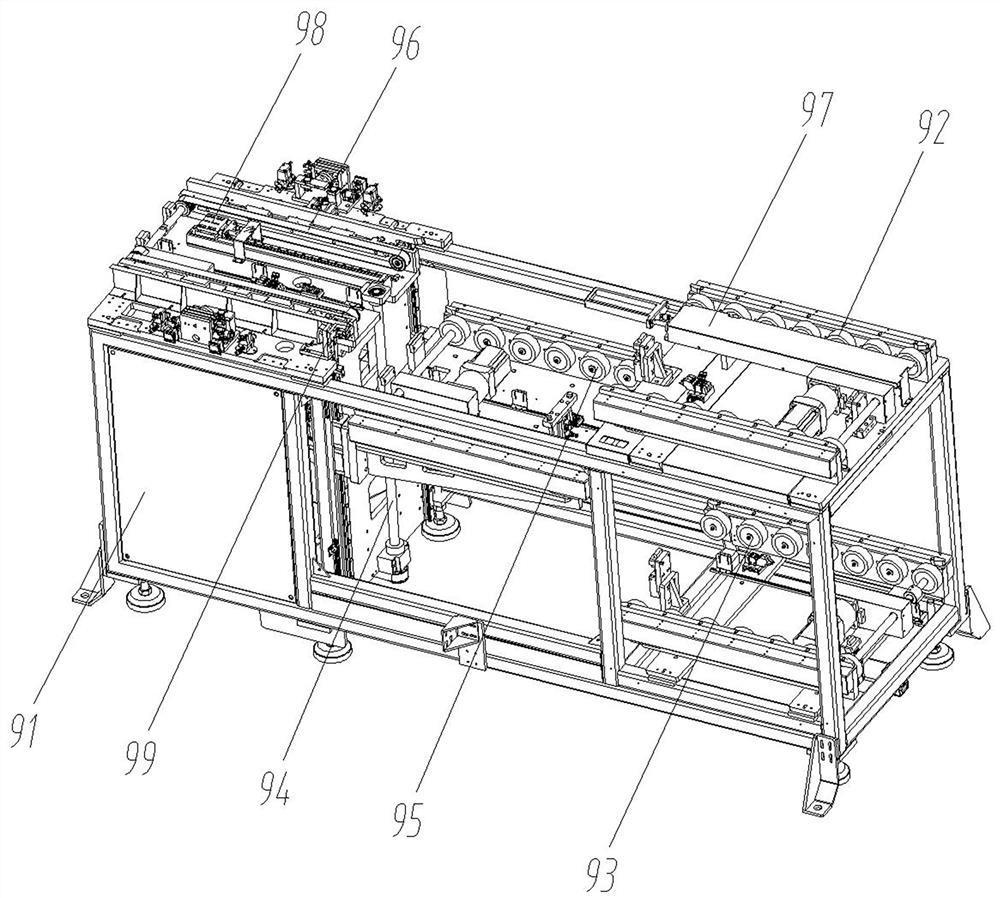

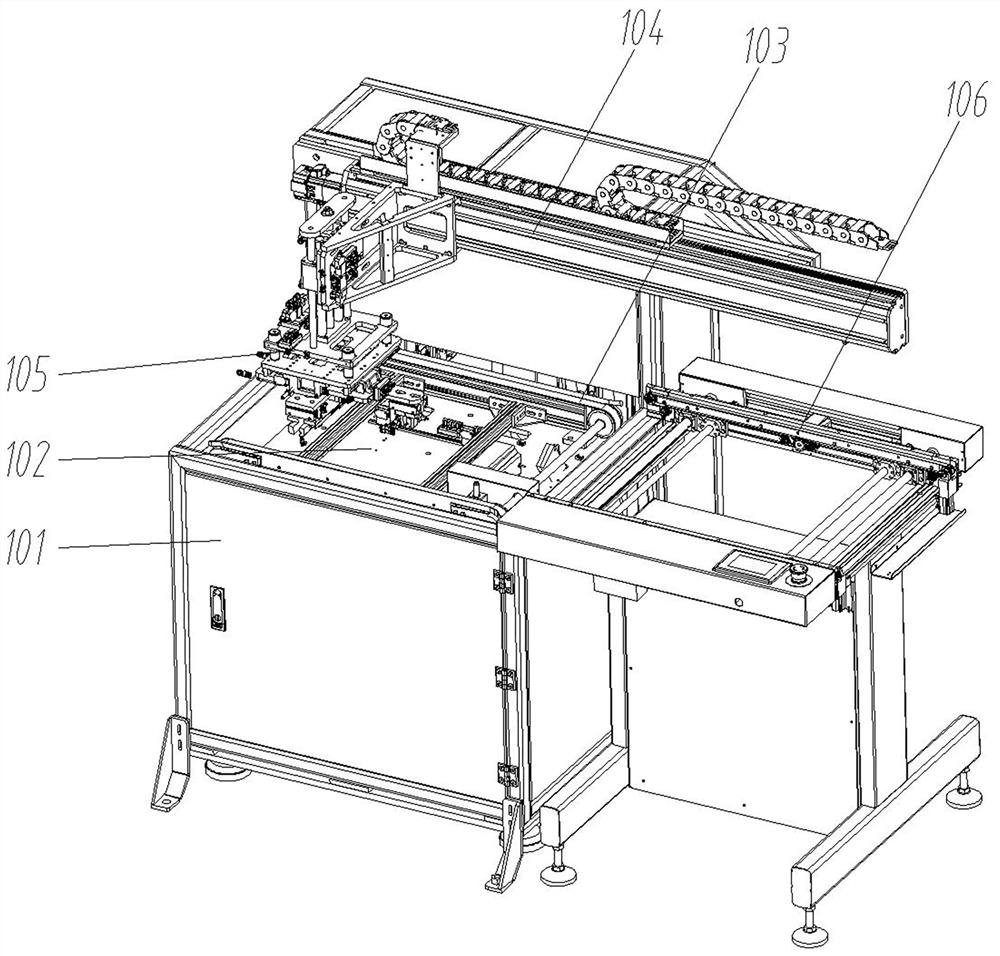

[0039] like figure 1 As shown, in this embodiment, the present invention includes a carrier conveying line 1 and a button battery and a cross-horse screw assembly device 2, an ICT automatic testing device 3, and a metal tray that are sequentially arranged along the conveying direction of the carrier conveying line 1. Feeding device 4, CPU hardware assembly device 5, radiator assembly device 6, handle and baffle assembly device 7 and protective cover and hard disk bracket assembly device 8, the button battery and cross-horse screw assembly device 2, all The ICT automatic test device 3, the metal tray feeding device 4, the CPU hardware assembly device 5, the radiator assembly device 6, the handle and the baffle assembly device 7, and the protective cover and Each of the hard disk bracket assembling devices 8 includes several groups of automatic feeding modules 9 . The present invention includes a carrier conveying line 1, and along the conveying direction of the carrier conveyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com