Method for preparing carbon nanotube reinforced aluminum-based composite material through metal 3D printing

A carbon nanotube, 3D printing technology, applied in the field of metal 3D printing, can solve the problems of low equipment requirements, high production efficiency, difficult preservation of carbon nanotube structure, and impact on the performance of final composite materials, etc., to improve organic compatibility, The effect of reducing the interface thermal resistance and shortening the development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

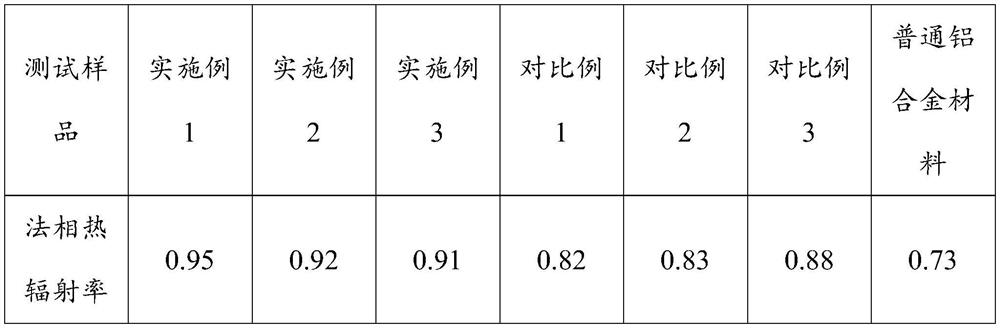

Examples

Embodiment 1

[0033] (1) Preparation of carbon nanotube dispersion: take carbon nanotubes, graphite powder, PVP (polyvinylpyrrolidone) and absolute ethanol and put them into a clean ball mill, vacuumize and perform ball milling to obtain a ball milled product carbon nanotube dispersion ; Wherein, the parts by weight of each material are: 4 parts of carbon nanotubes (multi-walled carbon nanotubes, particle size is 40-60nm), 15 parts of graphite powder (the specification is 3000 mesh, the purity is 99.99%), 0.4 parts of PVP ( Polyvinylpyrrolidone), the balance is absolute ethanol; the mass ratio of grinding ball to material is 5:1, the ball milling time is 30-60min, the ball milling speed is 1500rpm, and the vacuum degree is 0.1×10 -2 Pa-1.0×10 -2 Pa;

[0034] (2) Equipped with carbon nanotube-modified aluminum-based powder: According to the proportion, take 1 part of carbon nanotube dispersion and 1 part of aluminum-based powder into a cleaned ball mill, vacuumize and perform ball milling t...

Embodiment 2

[0037] (1) Preparation of carbon nanotube dispersion: take carbon nanotubes, graphite powder, PVP (polyvinylpyrrolidone) and absolute ethanol and put them into a cleaned ball mill, vacuumize and perform ball milling to obtain a ball milled product carbon nanotube dispersion ; Wherein, the parts by weight of each material are: 2 parts of carbon nanotubes (multi-walled carbon nanotubes, particle size 40-60nm), 20 parts of graphite powder (mass fraction is 99.99%), 0.2 parts of PVP (polyvinylpyrrolidone), The balance is absolute ethanol; the mass ratio of grinding ball to material = 3:1, the ball milling time is 30-60min, the ball milling speed is 1000rpm, and the vacuum degree is 0.1×10 -2 Pa-1.0×10 -2 Pa;

[0038] (2) Equipped with carbon nanotube-modified aluminum-based powder: According to the proportion, take 1 part of carbon nanotube dispersion and 1 part of aluminum-based powder into a cleaned ball mill, vacuumize and perform ball milling to obtain a ball-milled product. ...

Embodiment 3

[0041] (1) Preparation of carbon nanotube dispersion: take carbon nanotubes, graphite powder, PVP (polyvinylpyrrolidone) and absolute ethanol and put them into a cleaned ball mill, vacuumize and perform ball milling to obtain a ball milled product carbon nanotube dispersion ; Wherein, the parts by weight of each material are: 3 parts of carbon nanotubes (multi-walled carbon nanotubes, particle size 40-60nm), 18 parts of graphite powder (mass fraction is 99.99%), 0.3 parts of PVP (polyvinylpyrrolidone), The balance is absolute ethanol; the mass ratio of grinding ball to material = 4:1, the ball milling time is 30-60min, the ball milling speed is 1200rpm, and the vacuum degree is 0.1×10 -2 Pa-1.0×10 -2 Pa;

[0042] (2) Equipped with carbon nanotube-modified aluminum-based powder: According to the proportion, take 1 part of carbon nanotube dispersion and 1 part of aluminum-based powder into a cleaned ball mill, vacuumize and perform ball milling to obtain a ball-milled product. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com