System and method for continuously preparing phenylhydroximic acid by using microreactor

A technology of phenylhydroxamic acid and microreactor, which is applied in the system field of preparing phenylhydroxamic acid, can solve the problems of many side reactions and low oximation rate, and achieves short reaction period, high commercial value, and product yield. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

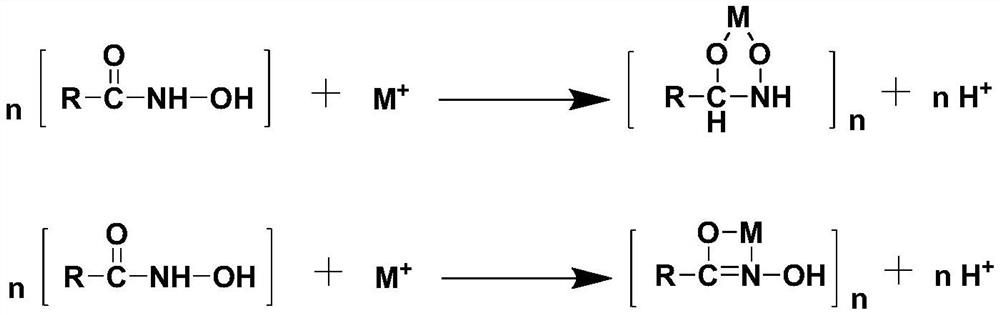

Method used

Image

Examples

Embodiment 1

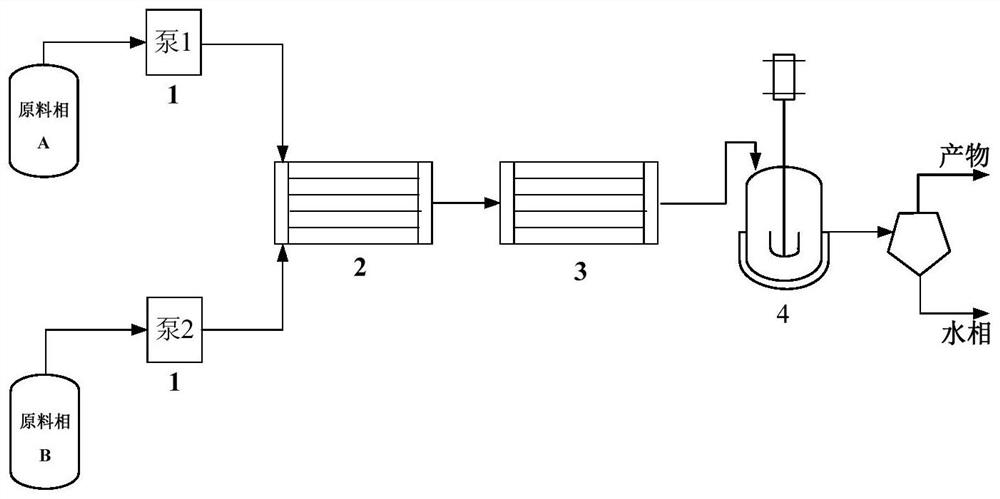

[0032] Example 1 Microreactor for continuous preparation of phenylhydroxamic acid

[0033] like figure 1 As shown, a micro-reaction system for preparing phenylhydroxamic acid, the micro-reaction system includes a first-stage microreactor 2 and a second-stage microreactor 3, a first-stage microreactor 2 and a second-stage microreactor The reactors 3 are connected in series through pipelines, the first-stage microreactor 2 and the second-stage microreactor 3 have built-in micro-heat exchangers, the first-stage microreactor 2 is connected to two advection pumps 1, and the second-stage microreactor The reactor 3 and the stirred tank 4 are connected by pipelines; the hydraulic diameter of the first-stage microreactor 2 and the second-stage microreactor 3 are both 0.5 mm and 25 cm in length.

[0034] The concrete steps that above-mentioned microreactor continuously prepares phenylhydroxamic acid are as follows:

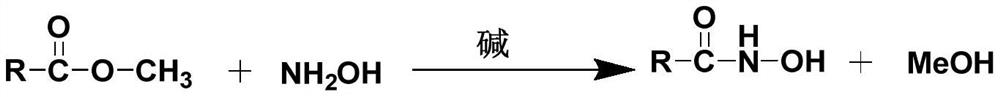

[0035] (1) First add sodium methoxide (0.5mol, 34g), anhydrous metha...

Embodiment 2-5

[0037] Example 2-5 Continuous preparation of phenylhydroxamic acid in a microreactor

[0038]The same system and method as in Example 1 were used for the continuous preparation of phenylhydroxamic acid. During the reaction, the reaction temperature of the microreactor was different from that in Example 1. In Examples 2-5, the reaction temperatures were controlled to be 20°C, 25°C, 30°C, and 40°C, respectively. The specific results are shown in Table 1.

[0039] Table 1. Effects of different temperatures on the reaction

[0040]

Embodiment 6-8

[0041] Example 6-8 Continuous Preparation of Phenyl Hydroxamic Acid in Microreactors

[0042] The same system and method as in Example 1 were used for the continuous preparation of phenylhydroxamic acid. During the reaction, the total residence time of the materials in the microreactor was different from that in Example 1. In Examples 6-8, the total residence time of the reaction materials in the two reactors was 1.6 minutes, 0.8 minutes and 0.5 minutes, respectively. The reaction solution enters the stirring tank 4, and the dilute hydrochloric acid adjusts the pH to 5 to 6, and a large amount of white solid product phenylhydroxamic acid appears. Suction filtration to obtain the product phenylhydroxamic acid, and the liquid chromatography area normalization method analyzes the component content. The specific results are shown in Table 2.

[0043] Table 2. Effects of different residence times on the reaction

[0044]

[0045] The system and method for continuously preparin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com