Industrial production method of cold-soluble black tea powder

A production method and technology for black tea powder are applied in the field of production and preparation technology of cold-dissolving tea powder, which can solve the problems that tea powder cannot meet complete cold-dissolving, high production condition requirements, redissolving of tea cheese and the like, and achieve a simple and smooth production process. , Low production accuracy requirements, suitable for industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

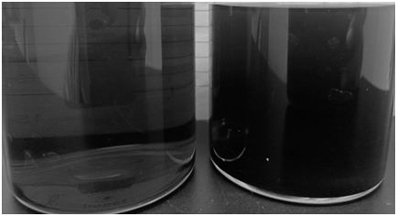

Image

Examples

Embodiment 1

[0032] a) After unpacking the 2t Dianhong tea leaves, grind them to 40 mesh with a pulverizer.

[0033] b) The crushed Dianhong tea leaves are fed into the countercurrent circulating extraction equipment, and the temperature of the circulating countercurrent extraction is controlled at 60°C; the feeding amount is controlled at 200kg per hour; the amount of water added is 3t per hour; and the extraction time is 30min. Extracted to obtain tea juice.

[0034] c) The tea juice obtained by extraction is cooled to 15°C by heat exchange, then calcium hydroxide is added to adjust the pH of the tea juice to 9, and the tea juice is allowed to settle for 30 minutes to precipitate the tea cheese.

[0035] d) Centrifuge the precipitation liquid disc to remove the precipitation, pump the tea juice into the vacuum tank, and charge the carbon dioxide to adjust the pH of the liquid. After the inflation is over, keep the pressure for 10-30min to allow the excess calcium to settle completely. ...

Embodiment 2

[0039] a) After unpacking 3 tons of Zhengshan Souchong black tea leaves, grind them to 60 mesh with a pulverizer.

[0040] b) Feeding the crushed Keemun black tea leaves into the countercurrent circulating extraction equipment, the temperature of the circulating countercurrent extraction is controlled at 80°C; the feeding amount is controlled at 250kg per hour; the water addition amount is 4t per hour; and the extraction time is 50min. Extracted to obtain tea juice.

[0041] c) The tea juice obtained by extraction is cooled to 5°C by heat exchange, then magnesium hydroxide is added to adjust the pH of the tea juice to 11, and it is left to settle for 60 minutes to precipitate the tea cheese.

[0042] d) After the precipitation liquid disc is centrifuged to remove the precipitation, the tea juice is pumped into a vacuum tank, and the pH of the material liquid is adjusted by charging carbon dioxide. After the aeration was completed, the pressure was maintained for 20 minutes to...

Embodiment 3

[0046] a) After unpacking 3 tons of Keemun black tea leaves, grind them to 50 mesh with a pulverizer.

[0047]b) Feed the crushed Keemun black tea leaves into the countercurrent circulating extraction equipment, and the temperature of the circulating countercurrent extraction is controlled at 70°C; the feeding amount is controlled at 300kg per hour; the water addition amount is 5t per hour; and the extraction time is 40min. Extracted to obtain tea juice.

[0048] c) The tea juice obtained by extraction is cooled to 25°C by heat exchange, then calcium hydroxide and magnesium hydroxide are added to mix precipitating agent at 1:1 (mass ratio), the pH of the tea juice is adjusted to 10, and the tea is allowed to settle for 45 minutes to precipitate the tea. cheese;

[0049] d) Centrifuge the precipitation liquid disc to remove the precipitation, pump the tea juice into a vacuum tank, and charge carbon dioxide to adjust the pH of the liquid. After the aeration is over, keep the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com