Microphone reinforcing flexible circuit board and preparation method thereof

A flexible circuit board, flexible circuit substrate technology, applied in the direction of printed circuit manufacturing, printed circuits, transducer circuits, etc., can solve the problem of microphone hole sound leakage, avoid microphone hole sound leakage, ensure high performance and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

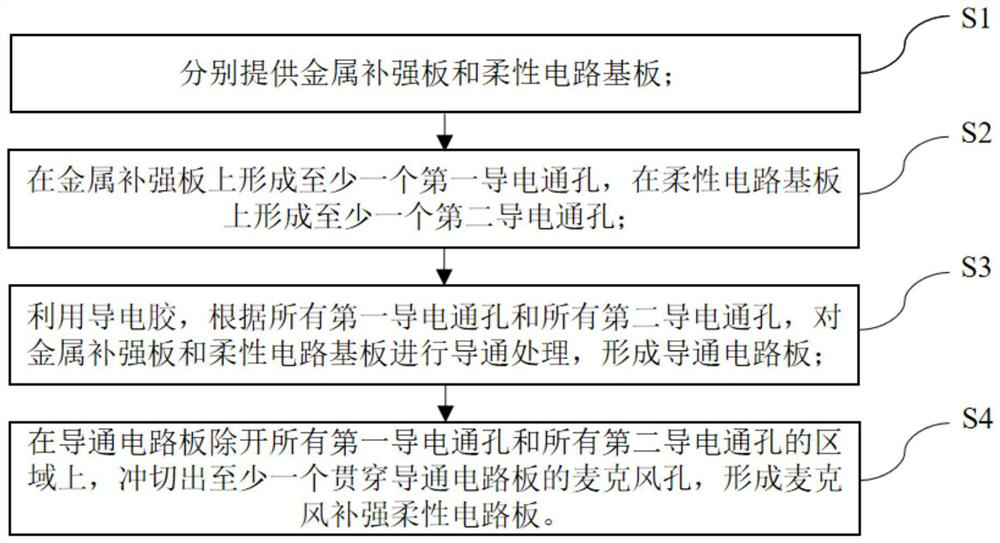

[0053] This embodiment provides a preparation method of a microphone reinforced flexible circuit board, such as figure 1 shown, including the following steps:

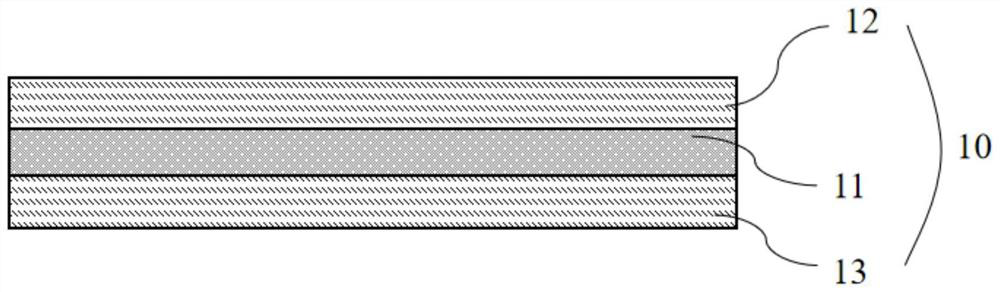

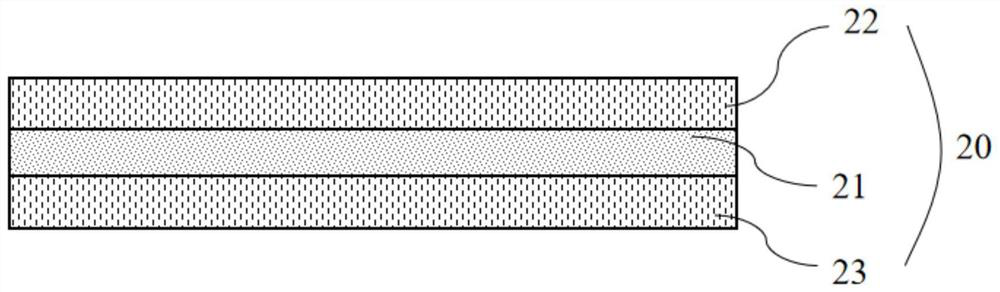

[0054] S1: Provide metal reinforcing plate and flexible circuit substrate respectively;

[0055] S2: forming at least one first conductive through hole on the metal reinforcing plate, and forming at least one second conductive through hole on the flexible circuit substrate;

[0056] S3: Conduct conduction processing on the metal reinforcing plate and the flexible circuit substrate according to all the first conductive through holes and all the second conductive through holes by using the conductive glue to form a conductive circuit board;

[0057] S4 : punching out at least one microphone hole penetrating the conductive circuit board on the area of the conductive circuit board except all the first conductive through holes and all the second conductive through holes to form a microphone reinforced flexible circuit bo...

Embodiment 2

[0106] This embodiment provides a microphone reinforced flexible circuit board, which is prepared by using the preparation method described in the first embodiment.

[0107] The microphone reinforced flexible circuit board in this embodiment can not only meet the requirement of reinforced grounding on the back of the microphone, but also avoid the problem of sound leakage through the microphone hole, thereby ensuring the high performance and high yield of the microphone.

[0108] The preparation method of the microphone reinforced flexible circuit board described in this embodiment is the same as the preparation method described in Embodiment 1. For details not described in this embodiment, please refer to Embodiment 1 and Figure 1 to Figure 8 The specific description is not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com