Polyamic acid, and thermosetting composition, cured film and liquid crystal display element using same

A polyamic acid, thermosetting technology, applied in the field of electronic parts, can solve the problem of few reports, etc., and achieve the effect of suppressing corrosion, high voltage retention rate, and high transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

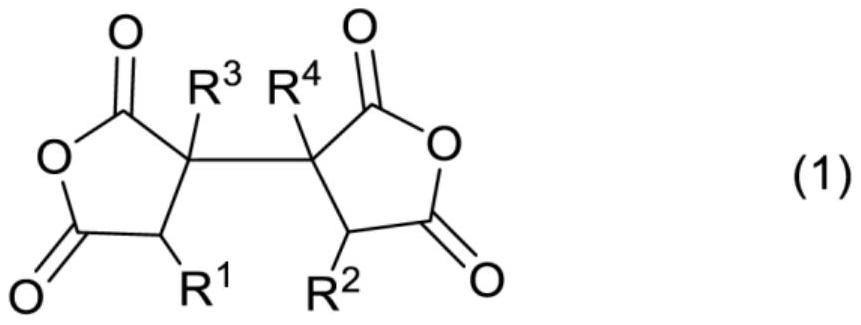

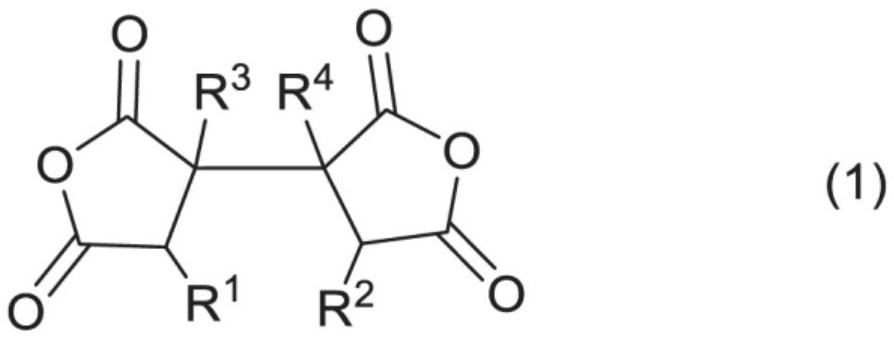

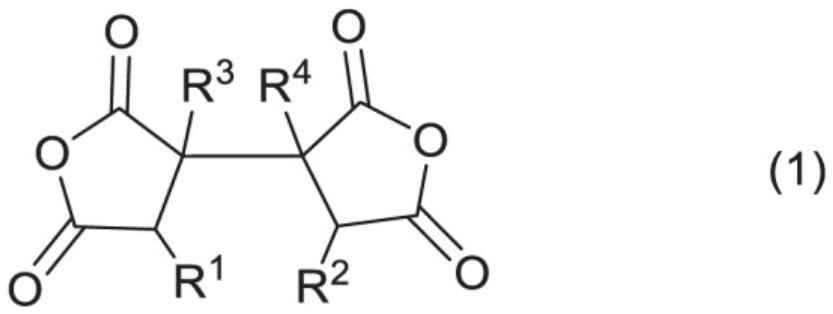

Image

Examples

preparation example Construction

[0119] 2-4. Preparation of thermosetting composition

[0120] The thermosetting composition of the present invention can be obtained by selectively adding a polyamic acid (A), a solvent (B2), a curing agent (C) as needed, a compound having a polymerizable double bond, a surfactant, Additives (D) such as adhesion improvers, antioxidants, and other additives are uniformly mixed and dissolved.

[0121] 2-5. Storage of thermosetting composition

[0122] When the thermosetting composition of the present invention is stored in the range of -30°C to 25°C, the stability over time of the composition becomes favorable, which is preferable. More preferably, it is -20 degreeC - 10 degreeC.

[0123] 3. Cured film obtained from thermosetting composition

[0124] A coating film can be formed by applying the thermosetting composition prepared as described above to the surface of a substrate by conventionally known coating methods such as spin coating, roll coating, dipping, and slit coatin...

Embodiment

[0129] Next, the present invention will be specifically described with reference to Synthesis Examples, Examples, and Comparative Examples, but the present invention is not limited to these Examples at all.

[0130] About the abbreviations described in the Examples, the corresponding compound names, trade names, etc. are described below.

[0131]

[0132] GBL: gamma-butyrolactone

[0133] ECa: Diethylene glycol monoethyl ether acetate

[0134] BCS: Ethylene Glycol Monobutyl Ether

[0135] PGME: Propylene Glycol Monomethyl Ether

[0136] EDM: Diethylene glycol ethyl methyl ether

[0137] 3MP: methyl 3-methoxypropionate

[0138]

[0139] BT-100: 1,2,3,4-butane tetracarboxylic dianhydride (Rikacid BT-100; trade name; New Japan Chemical Co., Ltd.)

[0140] ODPA: 3,3',4,4'-diphenyl ether tetracarboxylic dianhydride

[0141]

[0142] DDS: 4,4'-diaminodiphenylsulfone

[0143] 1,3-BAC: 1,3-bisaminomethylcyclohexane

[0144] NBDA: Bis(aminomethyl)norbornane (trade name; M...

Synthetic example 1

[0193] [Synthesis example 1] Synthesis of polyamic acid (A1)

[0194] At room temperature, BT-100 (27.94 g; 141.02 mmol), 1,3-BAC (20.06 g; 141.02 mmol) and GBL ( 144.00g). The reaction vessel was heated in an oil bath maintained at 85° C. for 2 hours, and it was confirmed that the contents in the reaction vessel were dissolved. After cooling to room temperature, BCS (48.00 g) was added, and the mixture was further stirred at 85°C for 5 hours. It cooled to room temperature, and obtained the solution of the uniform transparent polyamic acid (A1) whose solid content density|concentration is 20.0%. Mw of the polyamic acid (A1) was 10,700, and Mn was 9,900. The solution (hereinafter referred to as SA1) was directly used for the preparation of the thermosetting composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com