Waterproof coating construction method and laying device for implementing waterproof coating construction method

A technology of waterproof coating and construction method, which is applied in the direction of architecture and building construction, etc., and can solve problems such as easy occurrence of air bubbles between waterproof coating and defoaming layer, weak adhesion between waterproof coating and defoaming layer, and poor waterproof effect of waterproof layer , to achieve the effect of improving waterproof effect, high waterproof effect and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

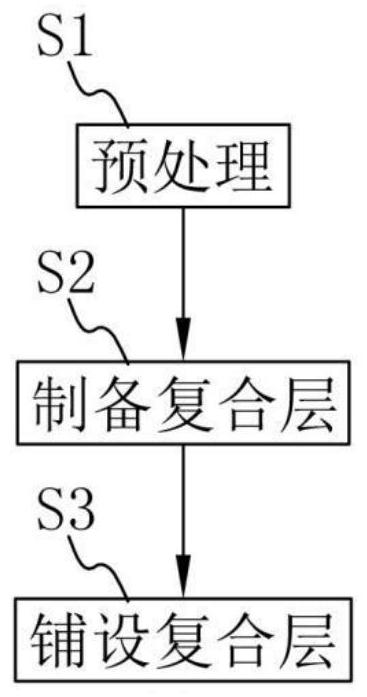

[0058] refer to figure 1 , a waterproof coating construction method, comprising the following steps:

[0059] S1. Pretreatment: Pretreatment of the base layer, cleaning the surface of the base layer, removing dust and other impurities on the surface of the base layer, and keeping the surface of the base layer dry.

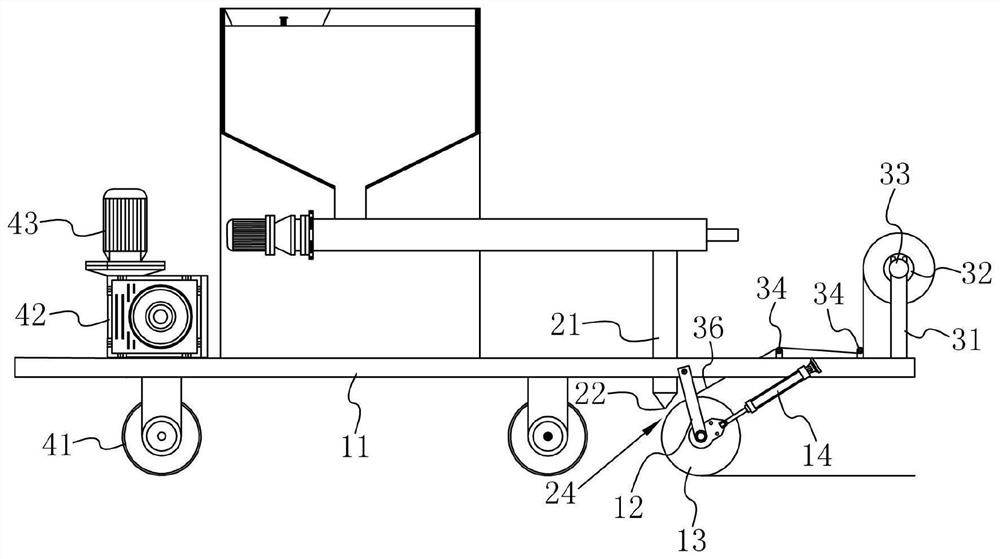

[0060] S2. Prepare the composite layer: prepare the carrier layer 36. The carrier layer 36 is preset on the unwinding assembly with the tension adjusting element 33. The carrier layer 36 can be a polymer film, a polyester mat, a glass fiber mat, or a glass fiber grid. One or more of cloth, cotton mixed fiber non-woven fabric, and non-woven fabric are mixed. In this embodiment, the carrier layer 36 is made of PET film, and the guide roller 13 of the unwinding assembly conveys the carrier layer 36; The carrier layer 36 is kept in a tensioned state during the waterproof coating; the waterproof coating is attached to the carrier layer 36 to form a composite layer; the...

Embodiment 2

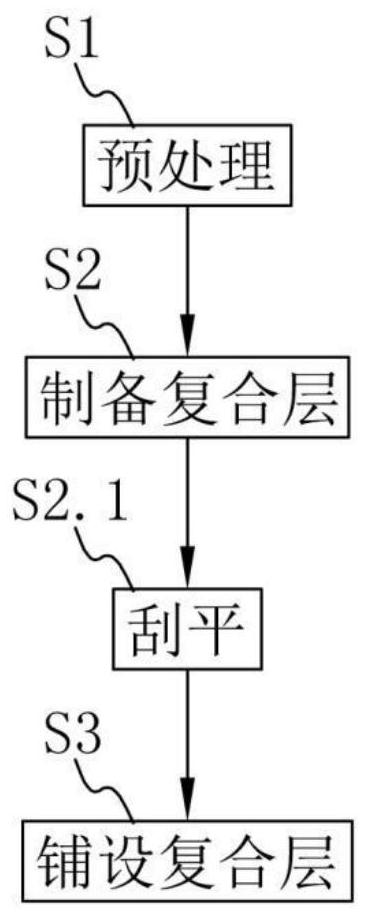

[0091] refer to image 3 , a waterproof coating construction method, comprising the following steps:

[0092] S1. Pretreatment: Pretreatment of the base layer, cleaning the surface of the base layer, removing dust and other impurities on the surface of the base layer, and keeping the surface of the base layer dry.

[0093] S2. Preparation of the composite layer: the carrier layer 36 is preset on the unwinding assembly with the tension adjusting element 33. In this embodiment, the carrier layer 36 is made of PET film, and the guide roller 13 of the unwinding assembly conveys the carrier layer 36; When the waterproof coating is attached to the carrier layer 36, the carrier layer 36 is kept in a tensioned state; the waterproof coating is attached on the carrier layer 36 to form a composite layer; Apply the waterproof paint; the waterproof paint in the coating die 21 flows down through the discharge port 22 to the carrier layer 36 on the upper surface of the guide roller 13; the ...

Embodiment 3

[0102] refer to Figure 5 , a waterproof coating construction method, comprising the following steps:

[0103] S1. Pretreatment: Pretreatment of the base layer, cleaning the surface of the base layer, removing dust and other impurities on the surface of the base layer, and keeping the surface of the base layer dry.

[0104] S2. Prepare the composite layer: prepare the carrier layer 36. The carrier layer 36 is preset on the unwinding assembly with the tension adjusting element 33. In this embodiment, the carrier layer 36 is made of PET film, and the guide roller 13 of the unwinding assembly conveys the carrier layer. 36; The carrier layer 36 is kept in a tensioned state when the waterproof coating is attached to the carrier layer 36; the waterproof coating is attached on the carrier layer 36 to form a composite layer; The upper surface of the roller 13 is coated with waterproof coating; the coating die 21 is used to attach the waterproof coating on the carrier layer 36, the coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com