Preparation method and application of thermoplastic shape memory epoxy resin

A flexible epoxy resin and epoxy resin technology, applied in the field of materials, can solve the problems of low fracture strain in mechanical properties and effective recycling of material shape memory effects, etc., to achieve improved fracture strain, excellent thermally induced shape memory performance, Effect of improving processing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The first step, according to the molar ratio of 16:1, weigh 3.69g of bisphenol A diglycidyl ether and 0.37g of polypropylene glycol diglycidyl ether at room temperature, and add an equivalent of 1.05g of diethylene glycol amine, add 0.3 g of polytrimethylene adipate plasticizer with a molecular weight of 2000; use a vortex shaker to stir and mix for 5 minutes;

[0027] The second step is to sonicate the mixed system in an ultrasonic cleaner for 5 minutes, then vortex stirring, and repeat the operation several times until the system becomes transparent and free of bubbles; the third step is to pour the evenly mixed epoxy resin system into In the mold, step heating and curing of 60°C / 2h+80°C / 2h+120°C / 2h is performed in an oven to obtain a thermoplastic shape memory epoxy resin.

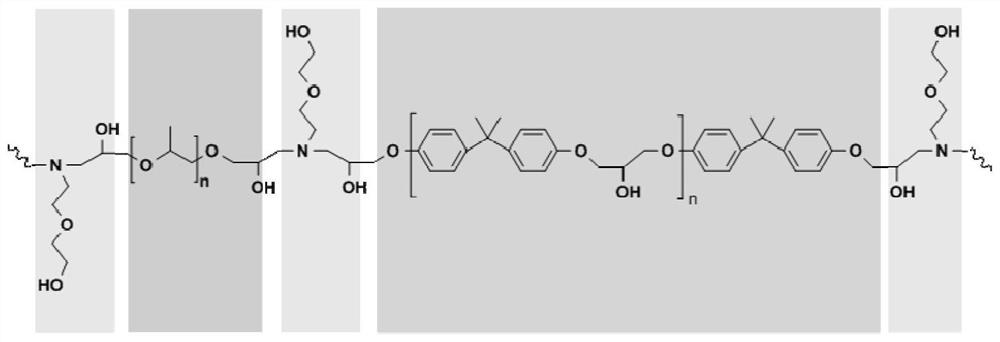

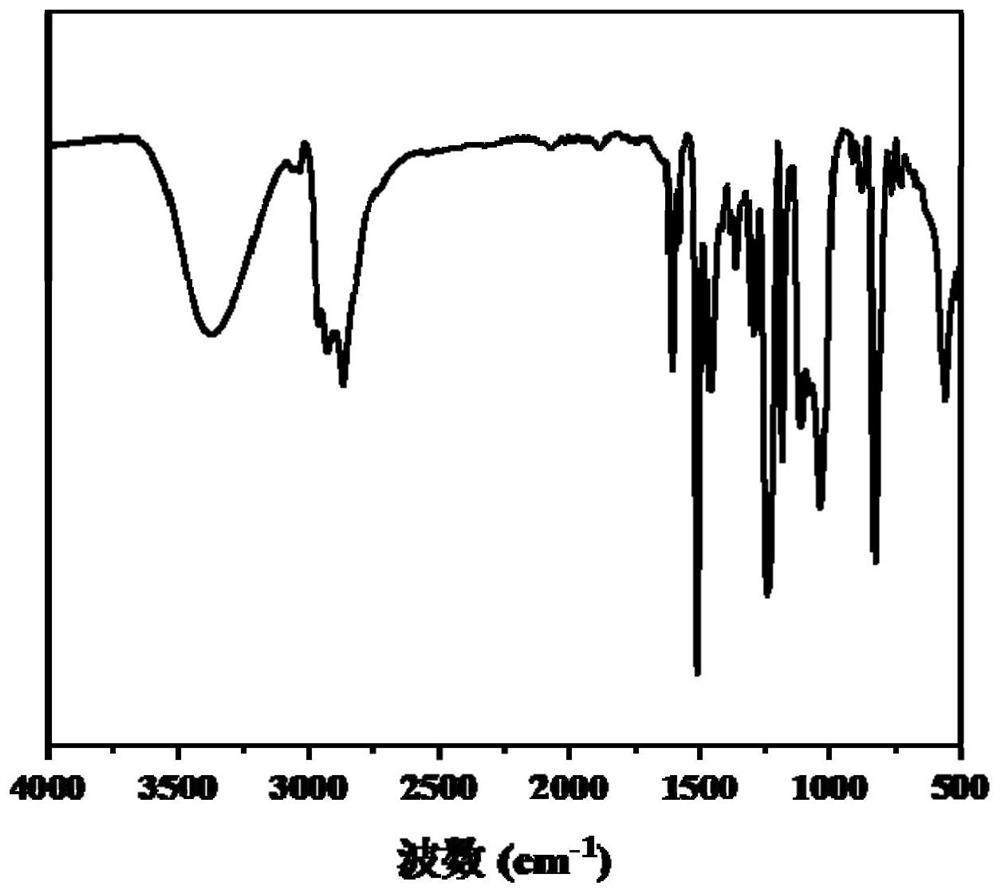

[0028] The chemical structural formula of the prepared thermoplastic shape memory epoxy resin is as follows: figure 1 shown. In the infrared spectrum test, the characteristic absorption peak of...

Embodiment 2

[0030] In the first step, according to the molar ratio of 12:1, 3.62g of bisphenol A diglycidyl ether and 0.48g of polypropylene glycol diglycidyl ether were weighed at room temperature, and an equivalent of 1.05g of diethylene glycol amine was added, Add 0.4 g of polycaprolactone diol plasticizer with a molecular weight of 1000; use a vortex shaker to stir and mix for 5 minutes;

[0031] The second step is to sonicate the mixed system in an ultrasonic cleaner for 5 minutes, then vortex stirring, and repeat the operation several times until the system becomes transparent and free of bubbles; the third step is to pour the evenly mixed epoxy resin system into In the mold, step heating and curing of 60°C / 2h+80°C / 2h+120°C / 2h is performed in an oven to obtain a thermoplastic shape memory epoxy resin.

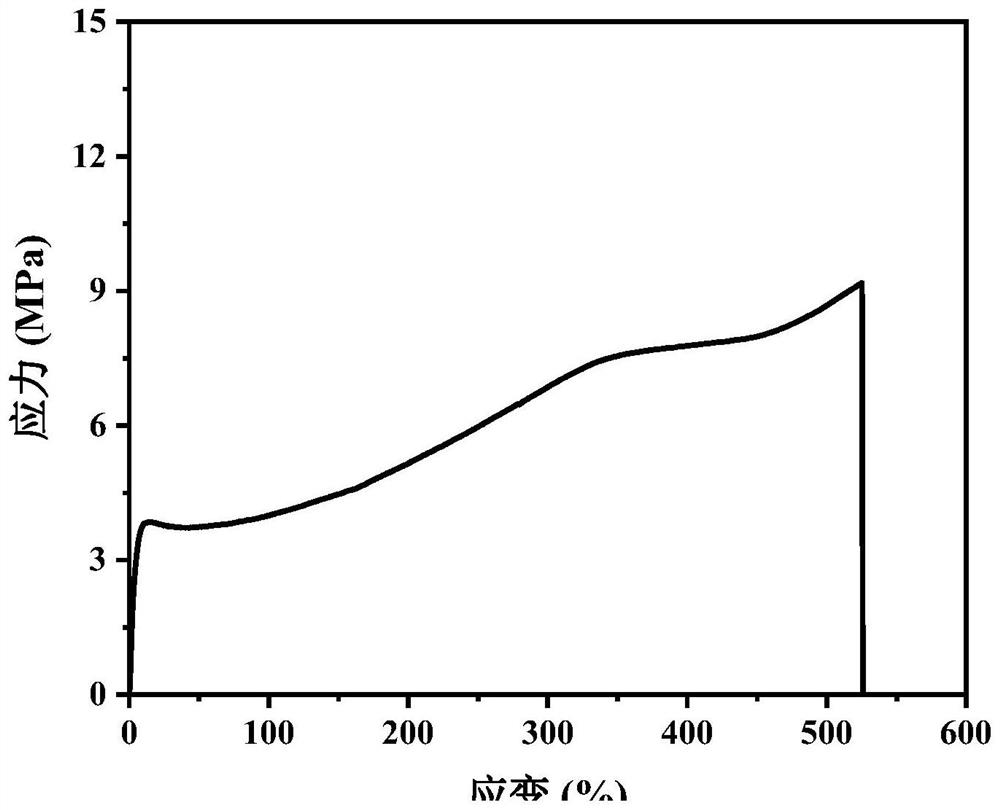

[0032] The mechanical properties of the prepared thermoplastic shape memory epoxy resin are as follows: image 3 shown, with a high fracture strain as high as 531.27%, which is favo...

Embodiment 3

[0036] In the first step, according to the molar ratio of 12:1, 3.62g of bisphenol A diglycidyl ether and 0.38g of polyethylene glycol diglycidyl ether were weighed at room temperature, and an equivalent amount of 1.05g of diethylene glycol was added. Amine, add 0.5g of polyester plasticizer (brand CCP-D1050) with a molecular weight of 2000; use a vortex shaker to stir and mix for 5min;

[0037] The second step is to sonicate the mixed system in an ultrasonic cleaner for 5 minutes, then vortex stirring, and repeat the operation several times until the system becomes transparent and free of bubbles; the third step is to pour the evenly mixed epoxy resin system into In the mold, step heating and curing of 60°C / 2h+80°C / 2h+120°C / 2h is performed in an oven to obtain a thermoplastic shape memory epoxy resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| fracture strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com