Method for continuously preparing dimethyl 2, 6-naphthalate slice

A dimethyl naphthalate and slicing technology, which is applied in the field of continuous preparation of 2,6-dimethyl naphthalate slicing, can solve problems such as low operating efficiency, increased energy consumption, and poor color, and achieve improved refining efficiency , increase energy consumption, the effect of less methanol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

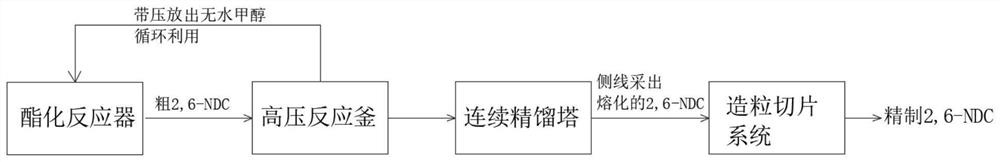

Method used

Image

Examples

Embodiment 1

[0058] The obtained crude 2,6-NDA (purity 98.0%) and anhydrous methanol were added to the esterification reactor, the mass ratio of 2,6-NDA to anhydrous methanol was 1:7.5, the catalyst sulfuric acid (8%wt) Under the action, the esterification reaction was carried out under the conditions of 170° C. and 2.4 MPa (gauge pressure), and the reaction was carried out for 5 hours. After the reaction was completed, after cooling, washing with deionized water and suction filtration, the obtained yellow flaky crystal was crude 2,6-NDC, the yield was 98.0%, the purity was 95.0%, and the chromaticity was 120.

[0059] Add the crude 2,6-NDC to the high pressure reaction kettle, the bottom discharge port of the kettle has a pressure-resistant sand core filter plate (pore size 7.5 microns), add 2.5 times the quality of 2,6-NDC anhydrous methanol, The mixture was heated to 160° C. for 30 minutes by stirring, and the mixture was cooled to 75° C., and the discharge valve was opened. Transfer t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com