Cultivation sewage circulation purification method

A technology for aquaculture sewage and recycling purification, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as high cost, low treatment cost, and non-normal operation of facilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

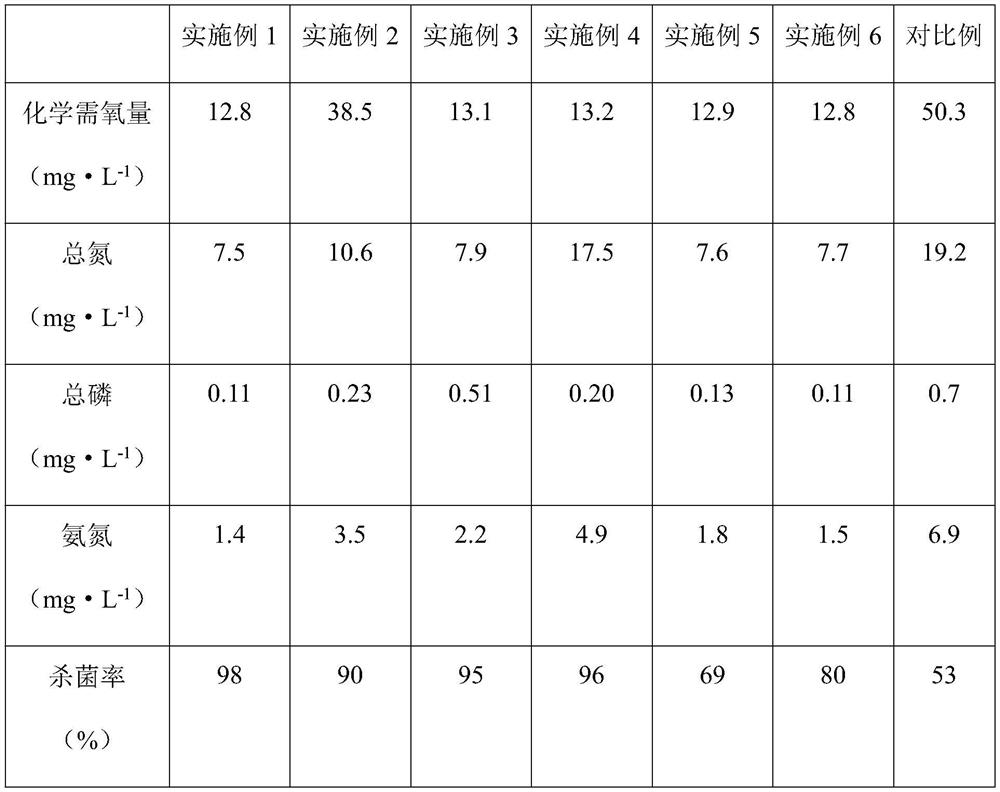

Examples

Embodiment 1

[0042] A method for circulating and purifying aquaculture sewage mainly comprises the following steps:

[0043] (1) After passing the aquaculture sewage through the artificial grille, it enters the water collecting well and is lifted to the inclined screen by the pump, and after being screened, the filtered sewage is obtained;

[0044] (2) The filtered sewage flows into the adsorption system, and after the adsorption in the adsorption system, the sewage can be adsorbed and treated;

[0045] (3) the adsorption treatment sewage will flow into the disinfection tank containing the bactericide, and after standing for 40min, the disinfection treatment sewage must be obtained;

[0046] (4) self-flow into the neutralization pond containing the neutralizing agent, and let it stand for 20 minutes to obtain the neutralized and treated sewage;

[0047] (5) After the neutralized sewage flows into the constructed wetland, it is transported to the farm.

[0048] Further, the grid in step (...

Embodiment 2

[0069] A method for circulating and purifying aquaculture sewage mainly comprises the following steps:

[0070] (1) After passing the aquaculture sewage through the artificial grille, it enters the water collecting well and is lifted to the inclined screen by the pump, and after being screened, the filtered sewage is obtained;

[0071] (2) The filtered sewage flows into the adsorption system, and after the adsorption in the adsorption system, the sewage can be adsorbed and treated;

[0072] (3) the adsorption treatment sewage will flow into the disinfection tank containing the bactericide, and after standing for 40min, the disinfection treatment sewage must be obtained;

[0073] (4) The sterilized treated sewage flows into the neutralization tank containing the neutralizing agent, and let it stand for 20 minutes to obtain purified water.

[0074] Further, the grid in step (1) is made of SS304 material, the grid gap is 5mm; the size of the water collecting well is 4.0m×1.5m×3....

Embodiment 3

[0093] A method for circulating and purifying aquaculture sewage mainly comprises the following steps:

[0094] (1) After passing the aquaculture sewage through the artificial grille, it enters the water collecting well and is lifted to the inclined screen by the pump, and after being screened, the filtered sewage is obtained;

[0095] (2) The filtered sewage flows into the adsorption system, and after the adsorption in the adsorption system, the sewage can be adsorbed and treated;

[0096] (3) the adsorption treatment sewage will flow into the disinfection tank containing the bactericide, and after standing for 40min, the disinfection treatment sewage must be obtained;

[0097] (4) self-flow into the neutralization pond containing the neutralizing agent, and let it stand for 20 minutes to obtain the neutralized and treated sewage;

[0098] (5) After the neutralized sewage flows into the constructed wetland, it is transported to the farm.

[0099] Further, the grid in step (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap