Preparation method of spheroidic alpha alumina for grinding and polishing

A technology of α-alumina and spherical shape, which is applied in chemical instruments and methods, polishing compositions containing abrasives, aluminum compounds, etc., can solve the problems that the hardness and surface uniformity of α-alumina cannot meet high-performance polishing, etc. Achieve the effect of excellent cutting force and polishing rate, concentrated distribution and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

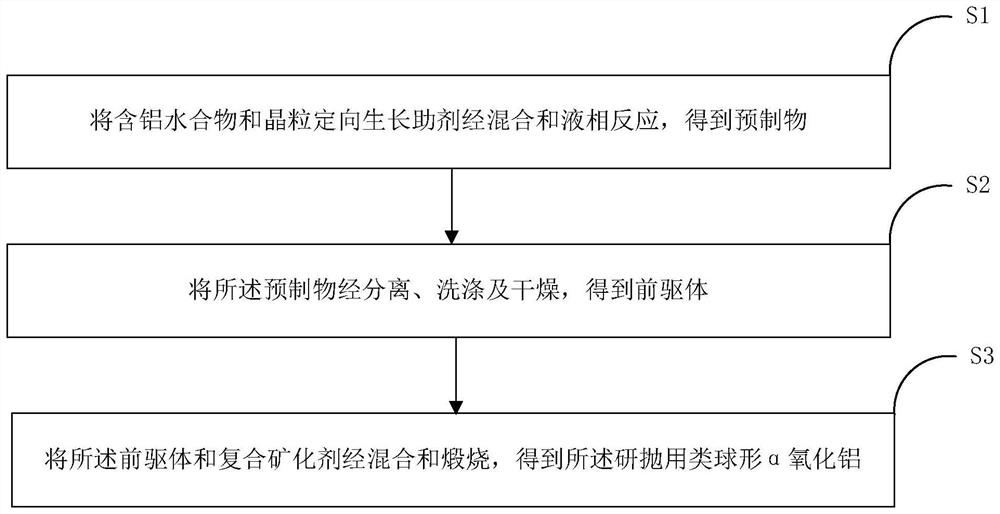

[0027] According to a typical embodiment of the present invention, there is provided a preparation method of spherical alpha alumina for grinding and polishing, comprising the following steps:

[0028] S1. The aluminum-containing compound and the grain-oriented growth aid are mixed and reacted in a liquid phase to obtain a prefabricated product.

[0029] S2. The preform is separated, washed and dried to obtain a precursor.

[0030] S3, mixing and calcining the precursor and the composite mineralizer to obtain the spherical α-alumina for grinding and polishing.

[0031] The preparation method of spherical α-alumina for grinding and polishing provided by the present invention, through the liquid phase reaction, the grain directional growth aid is uniformly coated on the surface of the aluminum-containing compound, mixed with the composite mineralizer and calcined, accompanied by the formation of α-alumina. The transformation of the crystal phase, the crystal is transformed from...

Embodiment 1

[0048] The present embodiment provides a preparation method of spherical α-alumina for grinding and polishing, and the steps are as follows:

[0049] S1, 100g of industrial alumina and 0.1g of magnesium chloride are mixed and reacted in liquid phase to obtain a prefabricated product.

[0050] Wherein: the temperature of the liquid phase reaction is 50 DEG C, the reaction time is 10min, and the heating mode is water bath heating.

[0051] S2. The preform is separated, washed and dried to obtain a precursor.

[0052] Wherein: the washing water is distilled water at 50°C, and the mass ratio of the distilled water to the aluminum-containing compound is 2:1.

[0053] S3, mixing and calcining the precursor and the composite mineralizer to obtain the spherical α-alumina for grinding and polishing.

[0054] Among them: the composite mineralizer includes fluoride and boron compound, the fluoride is aluminum fluoride, and the boride is boric acid;

[0055] The mass ratio of the fluor...

Embodiment 2

[0058] The present embodiment provides a preparation method of spherical α-alumina for grinding and polishing, and the steps are as follows:

[0059] S1. 100g of industrial alumina and 0.5g of magnesium chloride are mixed and reacted in a liquid phase to obtain a prefabricated product.

[0060] Wherein: the temperature of the liquid phase reaction is 80°C, the reaction time is 30min, and the heating mode is water bath heating.

[0061] S2. The preform is separated, washed and dried to obtain a precursor.

[0062] Wherein: the washing water is distilled water at 80°C, and the mass ratio of the distilled water to the aluminum-containing compound is 3:1.

[0063] S3, mixing and calcining the precursor and the composite mineralizer to obtain the spherical α-alumina for grinding and polishing.

[0064] Among them: the composite mineralizer includes fluoride and boron compound, the fluoride is calcium fluoride, and the boron is boric acid;

[0065] The mass ratio of the fluoride ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com