Application of Fe-based metal organic framework material as combustion catalyst

A technology of combustion catalysts and organic frameworks, applied in organic compound/hydride/coordination complex catalysts, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve problems such as catalytic efficiency limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1 Mixed ligand MIL-101(Fe)-NH 2 - R % Material preparation

[0022] Synthetic series MIL-101(Fe)-NH 2 - R % ( R = 0, 9, 19, 28, 38, 48) mixed ligand materials, where R is the ratio of 2-aminoterephthalic acid ligands to total ligands (terephthalic acid and 2-aminoterephthalic acid). The specific experimental scheme is as follows: Weigh FeCl separately 3 ·6H 2 O (324 mg), terephthalic acid (H 2 BDC, 100, 90, 80, 70, 60 mg) and 2-aminoterephthalic acid (NH 2-BDC, 0, 10, 20, 30, 40, 50 mg) was dissolved in N,N dimethylformamide (DMF, 7.5 mL), after sonication for 15 minutes, the above mixed solution was transferred to the reactor, and then The reaction was heated at 125 °C for 12 h in an oven, cooled to room temperature, washed three times with DMF and ethanol, and the product obtained by centrifugation was dried at 70 °C overnight.

Embodiment 2

[0023] Example 2 Preparation of HP-MIL-101(Fe) material

[0024] Based on the mixed ligand MIL-101(Fe)-38% material synthesized in Example 1, the obtained tan powder MIL-101(Fe)-NH 2 -38% raw materials were put into a muffle furnace and heated at different temperatures (320, 300, 280, 260 and 200 °C) for 30 min to obtain HP-MIL-101(Fe)- X ( X = 320, 300, 280, 260 and 200 °C) etc. After cooling to room temperature, it was placed in a vacuum drying oven and activated at 100 °C for 6 hours. Finally, after cooling to room temperature, the obtained solid powder was transferred to a 6 ml centrifuge tube and stored in a sealed and dry condition.

Embodiment 3

[0025] Example 3 Mixed ligand MIL-101(Fe)-NH 2 - R %Material structure and morphology analysis

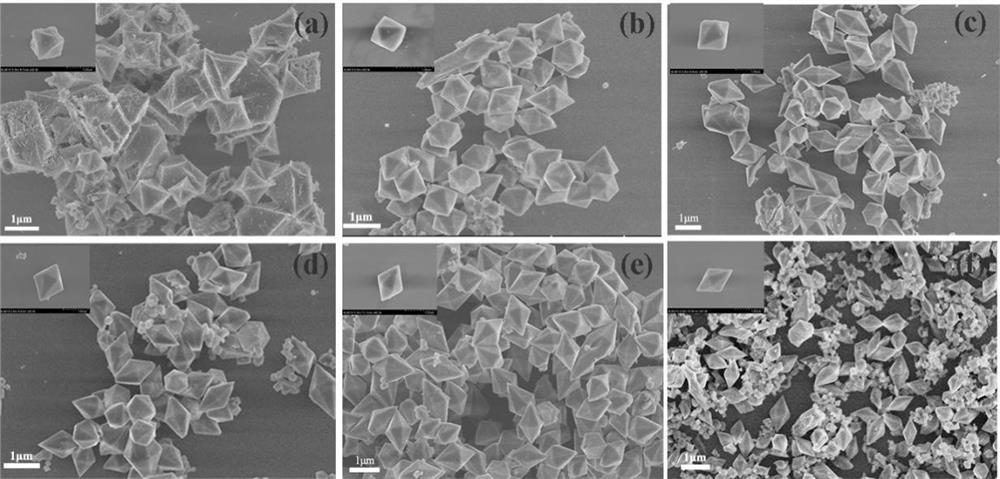

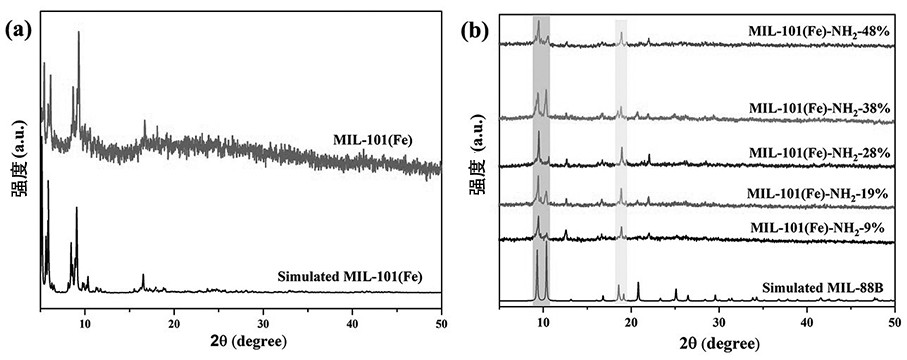

[0026] (1) MIL-101-NH 2 - R %Material Morphology Analysis

[0027] The microstructure of the material was first characterized by scanning electron microscopy (SEM). One-pot synthesis of different NH 2 -H 2 MIL-101(Fe)-NH in BDC ratio 2 - R % ( R = 0, 9, 19, 28, 38, 48) materials such as figure 1 shown. MIL-101(Fe)-NH 2 -0% exhibits a typical octahedral shape and is uniformly distributed. With NH 2 - Increased proportion of BDC ligands, MIL-101(Fe)-NH 2 - R % ( R = 9, 19, 28, 38, 48) were similar in morphology to MIL-88B, showing a spindle morphology with an average size of 1 μm in length and about 500 nm in diameter. However, when the doping ratio is too high, the mixed ligand MIL-101(Fe)-NH 2 -48% may have a strong competitive reaction, each forming a single-ligand MOF with uneven distribution.

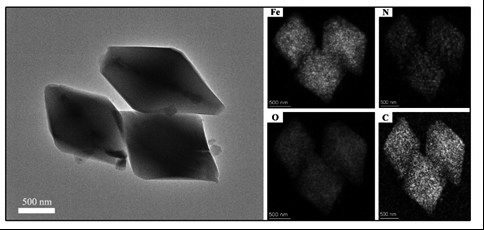

[0028] To further confirm the successful introduction of NH to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat release | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com