Method for preparing hydrophobic silicon dioxide aerogel felt under normal pressure

A technology of hydrophobic silica and airgel felt, which is applied to ceramic products, household utensils, and other household utensils. It can solve the problems of uneven hydrophobization of the gel, increased production costs, and long reaction cycles. Large-scale continuous production, elimination of dead ends, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

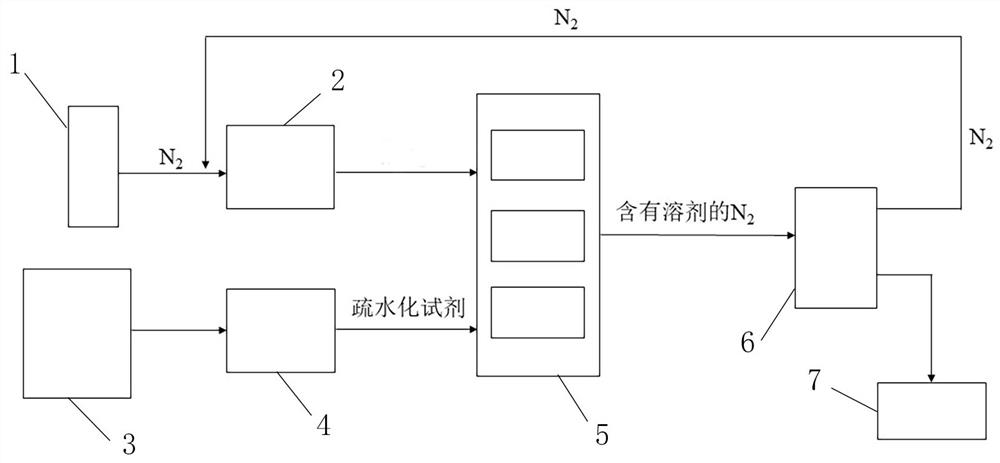

[0033] refer to figure 1, a method for preparing hydrophobic silica aerogel felt at normal pressure, using a device for preparing hydrophobic aerogel at normal pressure, the device comprises: a nitrogen generator 1, a nitrogen heater 2, and a hydrophobizing reagent replenishing tank 3 , reagent tank 4, hydrophobic drying box 5, solvent recovery device 6 and solvent tank 7 and other preparation components, the preparation components are connected by a plurality of pipelines that play a communication role and valves arranged on the pipelines, and the valves can control the connected pipelines. Whether the connection between the preparation components at both ends is not.

[0034] Each hydrophobic drying box 5 includes two inlets and one outlet, and its outer wall is wrapped with a thermal insulation layer with thermal insulation effect. The thermal insulation layer can be made of aerogel felt, aerogel composite board, and foam composite board One or more of the thermal insulati...

Embodiment 2

[0046] The preparation parts and the connection relationship are the same as those in Example 1. A method for preparing hydrophobic silica aerogel felt at normal pressure, by nitrogen generator 1, nitrogen heater 2, hydrophobizing reagent replenishing tank 3, reagent tank 4, hydrophobic drying box 5, solvent recovery device 6 and solvent tank 7 and other preparation equipment are prepared, and the preparation steps are as follows:

[0047] (1), take silicon source, ethanol and water and mix evenly, then add catalyst and stir evenly to obtain silica sol; wherein, in terms of molar ratio, it is obtained by mixing silicon source:ethanol:water=1:6:2; The source is ethyl orthosilicate and methyl orthosilicate, and the catalyst is ammonium fluoride solution;

[0048] (2) After immersing the fiber mat in the silica sol obtained in step (1) for 12 hours, static aging at 60°C for 8 hours;

[0049] (3), place the silica wet gel felt obtained in step (2) in the hydrophobic drying box 5...

Embodiment 3

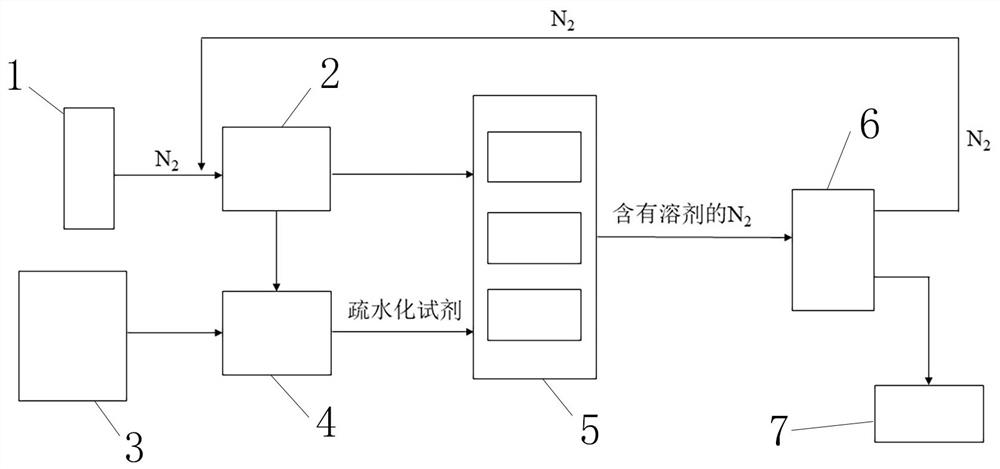

[0054] refer to figure 2 , a method for preparing hydrophobic silica aerogel felt at normal pressure, prepared by a device for preparing hydrophobic aerogel at normal pressure, the device comprising: a nitrogen generator 1, a nitrogen heater 2, a hydrophobizing reagent replenishing tank 3. Reagent tank 4, hydrophobic drying box 5, solvent recovery device 6, solvent tank 7, several pipes and valves.

[0055] The difference from Example 1 is that the nitrogen heater 2 transports nitrogen to the inlet of the hydrophobic drying box 5 and the reagent tank 4 through two pipelines and valves arranged on the pipelines, respectively.

[0056] The working process is as follows: Nitrogen is prepared by the nitrogen generator 1. First, the nitrogen heater 2 is not turned on, the valve on the pipeline between the nitrogen heater 2 and the reagent tank 4 is closed, and the connection between the nitrogen heater 2 and the hydrophobic drying box 5 is maintained. To ensure the smooth flow of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com