High-dispersity activated carbon supported metal catalyst and preparation method thereof

A metal catalyst, high-dispersion technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, chemical instrument and method, physical/chemical process catalyst, etc., can solve the impact, unfavorable dispersion and stability of loaded metal And other problems, to achieve good stability, high catalytic activity and stability, high dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

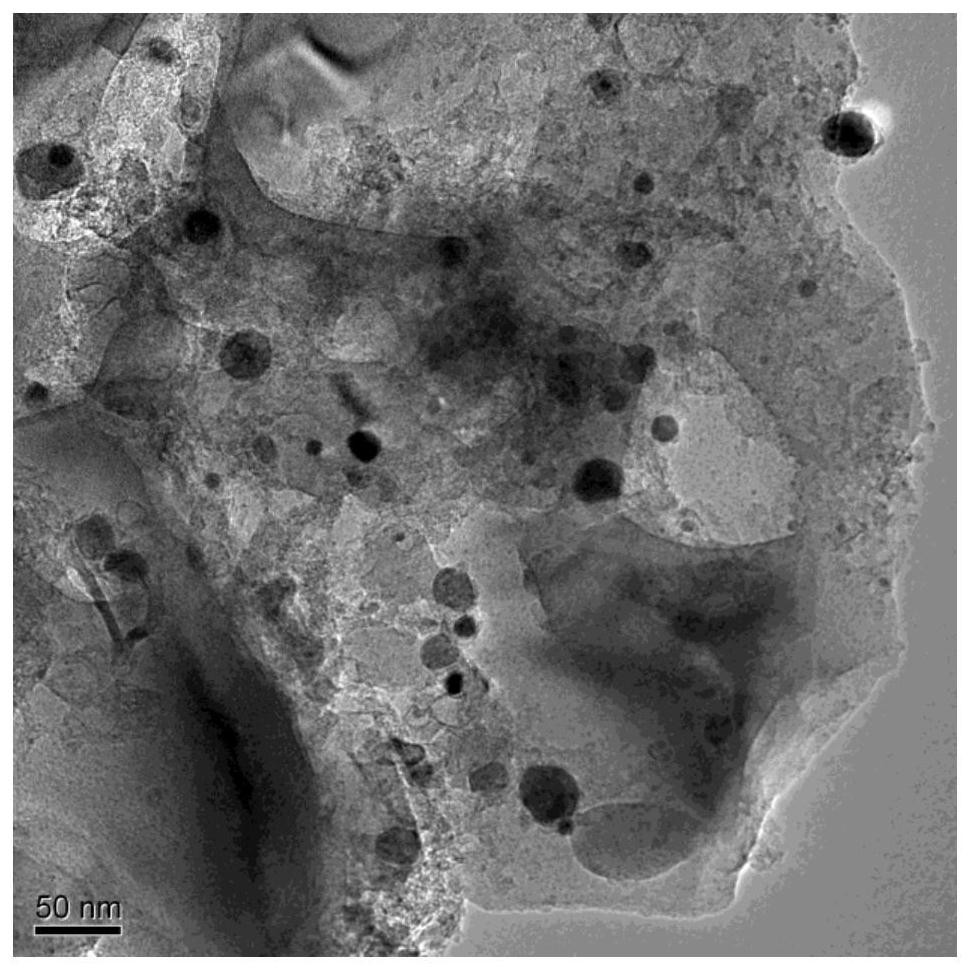

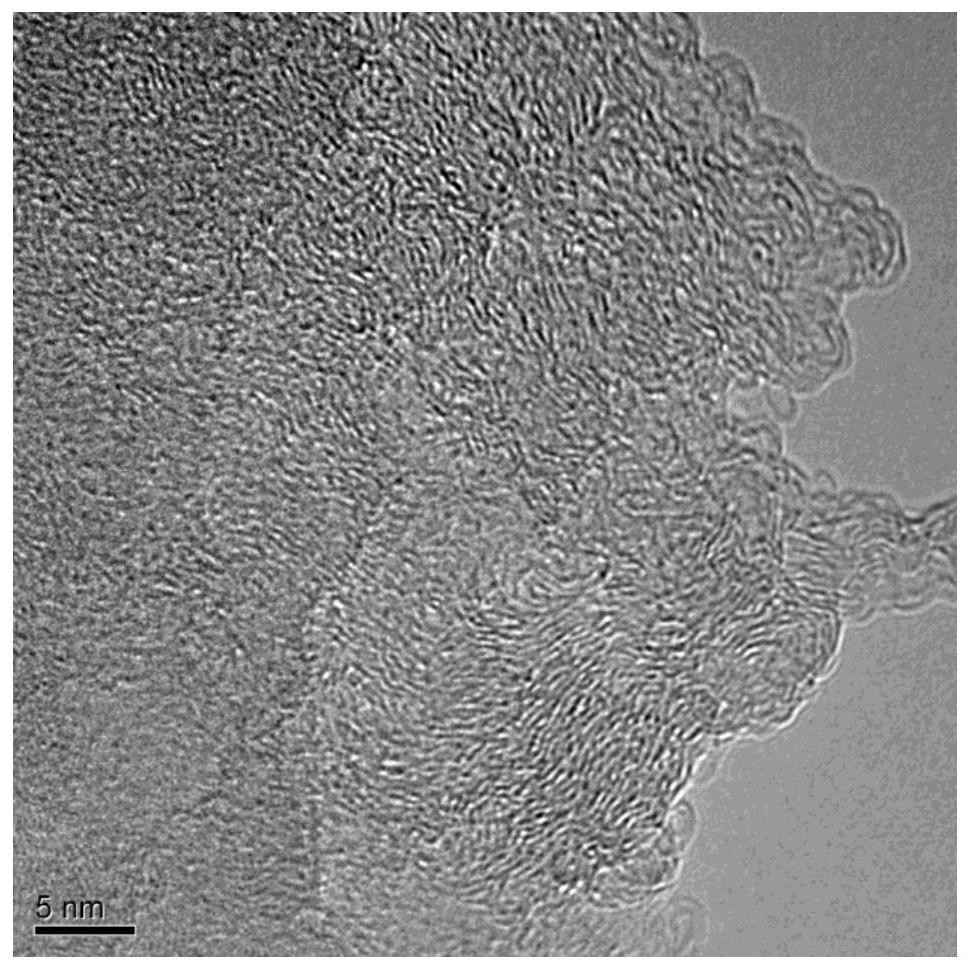

[0026] Mix 6g of activated carbon with 300mL and 6mol / L of hydrochloric acid, stir magnetically for 24 hours at room temperature, then wash with deionized water until neutral, and dry at 150°C for 24 hours to obtain activated carbon washed with hydrochloric acid. like figure 1 and figure 2 As shown, through transmission electron microscope observation, the impurity particles on the surface are obviously reduced, and the surface is more regular.

Embodiment 2

[0028] Mix 6 g of activated carbon with 300 mL of 6 mol / L nitric acid, stir magnetically for 24 hours at room temperature, then wash with deionized water until neutral, and dry at 150°C for 24 hours to obtain nitric acid-washed activated carbon. like image 3 As shown, through transmission electron microscope observation, the impurity particles on the surface are obviously reduced, and the surface is more regular.

Embodiment 3

[0030] Weigh 10.45mg of chloroauric acid tetrahydrate reagent and dissolve it in 10mL of aqua regia, then add dropwise to 5g of activated carbon after acid washing with hydrochloric acid and stir evenly. After drying in a vacuum oven for 24 hours, a hydrochloric acid-modified activated carbon-supported gold catalyst with a high-dispersion gold loading of 0.1 wt% was obtained. like Figure 4 As shown, through transmission electron microscope observation, the surface of the activated carbon is uniformly distributed with highly dispersed gold particles with a particle size of 1-3 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com