Preparation and application of bismuth titanate-coated NH2-MIL-125 photocatalyst

A NH2-MIL-125, photocatalyst technology, applied in the direction of physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, chemical instruments and methods, etc., can solve low light response, low conductivity, Hinder the application and other problems, to achieve the effect of inhibiting recombination and improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] NH 2 -The preparation method of MIL-125 includes the following steps:

[0031](1) 2-Aminoterephthalic acid (2.86 g, 15.8 mmol) was added to a mixed solution of 10 mL of anhydrous methanol and 40 mL of anhydrous N,N-dimethylformamide, and stirred at room temperature until 2 - The aminoterephthalic acid dissolves completely. Next, titanium isopropoxide (2.86 mL, 9.7 mmol) was added to the above mixed solution, then transferred to a 100 mL polytetrafluoroethylene-lined autoclave, and heated at 110° C. for 72 h. Let stand to cool to room temperature;

[0032] (2) the solid obtained by centrifugation in (1) is immersed in DMF and anhydrous methanol successively and soaked twice and centrifugally washed;

[0033] (3) Vacuum-dry the solid obtained in (2) at 100° C. for 12 h to obtain NH 2 -MIL-125.

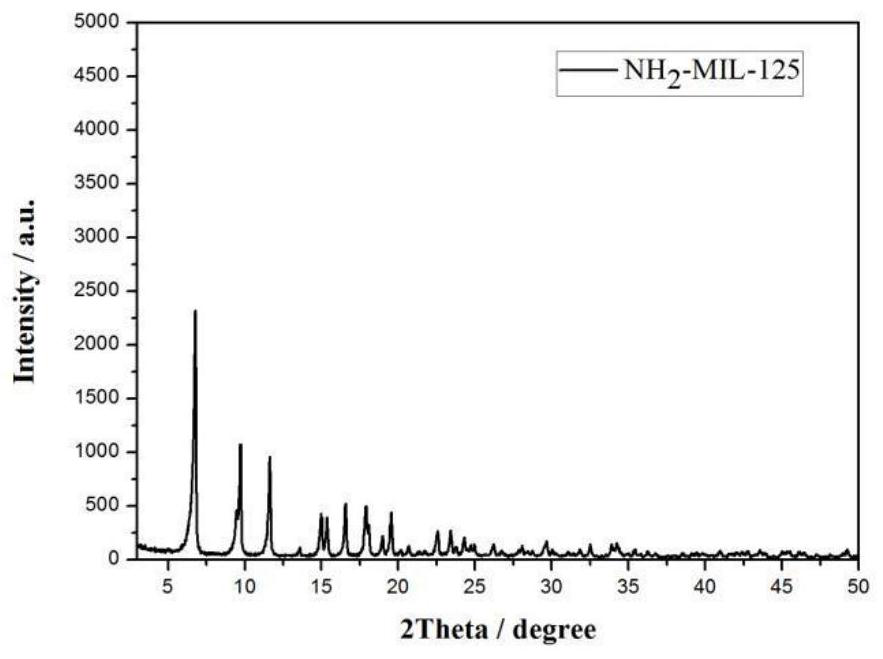

[0034] like figure 1 shown. from figure 1 The XRD pattern can be seen with the predecessors made of NH 2 - The XRD patterns of MIL-125 are consistent, indicating that our...

Embodiment 2

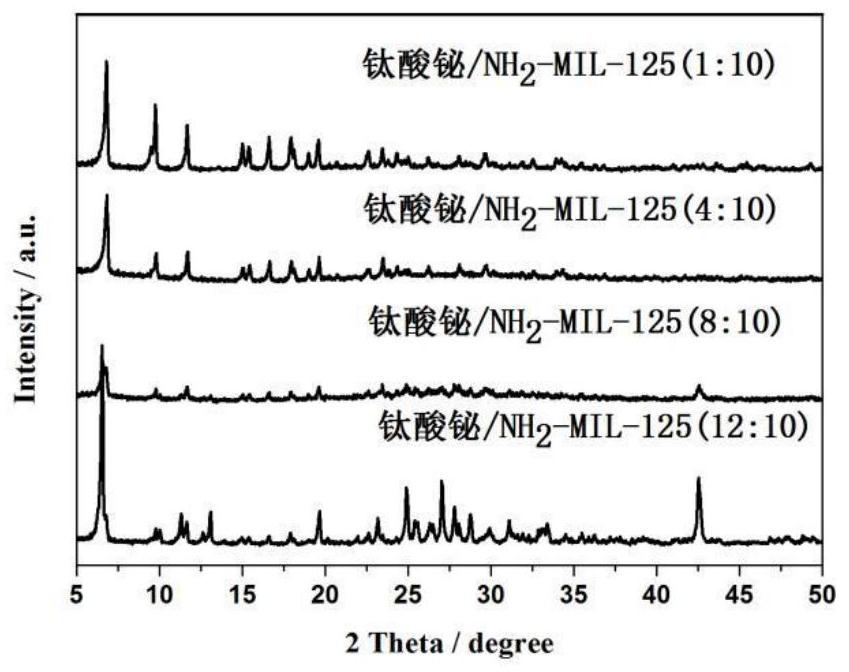

[0039] Bismuth Titanate@NH 2 -The preparation method of MIL-125 (1:10) material includes the following steps:

[0040] (1) Take 300mg of NH 2 -MIL-125 is poured into a clean beaker, followed by 50mL of HNO 3 (1 mmol / L) aqueous solution, ultrasonically dissolved, then added 30 mg of bismuth nitrate pentahydrate, ultrasonicated for 15 min to dissolve, and then the mixed solution was stirred at room temperature for 7 h;

[0041] (2) the solid obtained by centrifugation in (1) is centrifuged and washed three times with deionized water and absolute ethanol alcohol respectively;

[0042] (3) The solid obtained in (2) was vacuum-dried at 80 °C for 12 h to obtain bismuth titanate@NH 2 -MIL-125 (1:10).

Embodiment 3

[0044] Bismuth Titanate@NH 2 -The preparation method of MIL-125 (4:10) material includes the following steps:

[0045] (1) Take 300mg of NH 2 -MIL-125 is poured into a clean beaker, followed by 50mL of HNO 3 (1mmol / L) aqueous solution, ultrasonically dissolved, then added 120mg bismuth nitrate pentahydrate, ultrasonicated for 15min to dissolve, and then the mixed solution was stirred and reacted at room temperature for 7h;

[0046] (2) the solid obtained by centrifugation in (1) is centrifuged and washed three times with deionized water and absolute ethanol alcohol respectively;

[0047] (3) The solid obtained in (2) was vacuum-dried at 80 °C for 12 h to obtain bismuth titanate@NH 2 -MIL-125 (4:10).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com