High-flux low-energy-consumption tetracycloheptane continuous flow synthesis device and method

A tetracycloheptane, low energy consumption technology, applied in the field of tetracycloheptane continuous flow synthesis device, can solve the problems of low power, low light intensity, small heat release, rapid temperature rise, etc., shorten the reaction time, reduce the unit energy The effect of consumption and increase of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

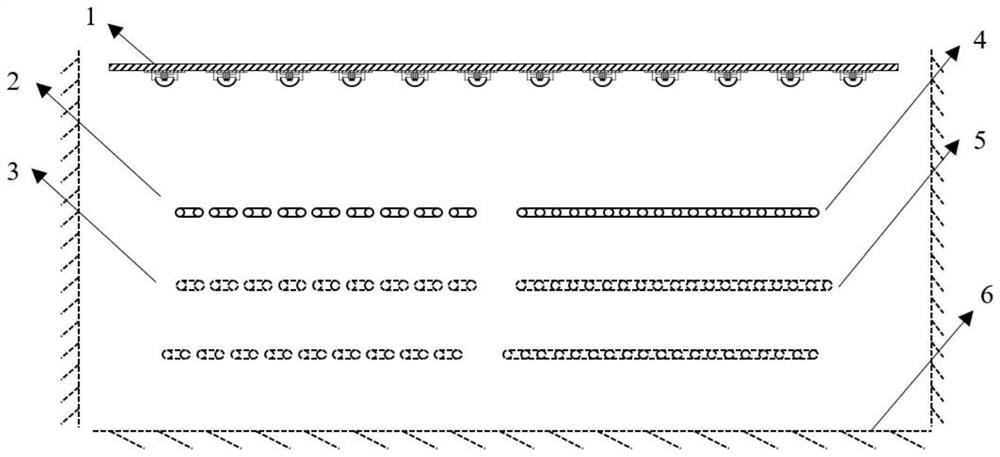

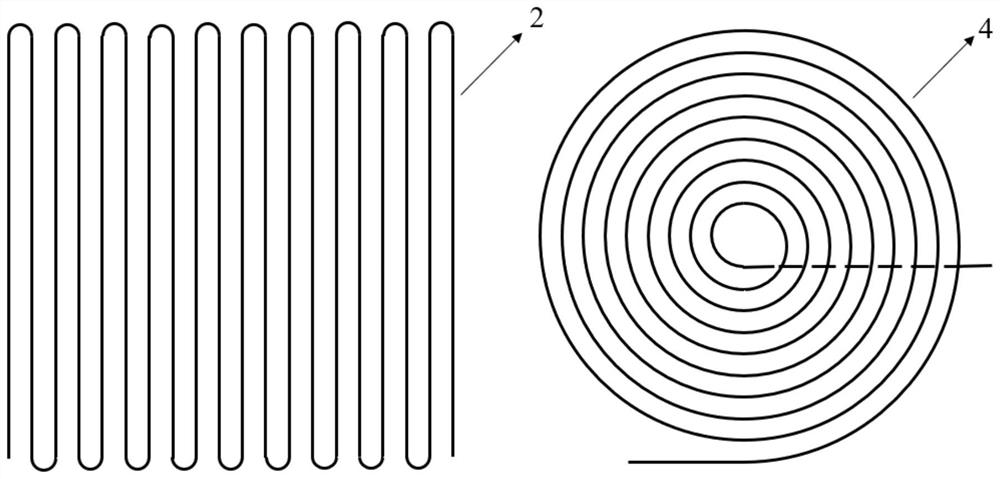

[0031] like figure 1 , figure 2 As shown, the tetracycloheptane continuous flow synthesis device of the present embodiment includes a serpentine arrangement capillary continuous flow reactor 2 formed by a serpentine arrangement of stacked capillaries 3, and a ring-shaped arrangement of stacked capillaries 5 formed by an annular arrangement. The capillary continuous flow reactor 4 is arranged, the upper part of the capillary continuous flow reactor 2 and the annular arrangement capillary continuous flow reactor 4 are provided with a high-power panel type UV-LED lamp 1, and the lower part is provided with a reflector 6.

[0032] The capillary continuous flow reactor is made of PFA, the inner diameter is 1mm, and the length is 16m.

[0033] The channels of the capillary continuous flow reactor are arranged in an annular shape and are arranged in a stacked manner, and the number of stacked layers is 2 layers.

[0034] The high-power panel UV-LED lamp emits ultraviolet light wit...

Embodiment 2

[0037] like figure 1 As shown, this embodiment includes a high-power panel UV-LED lamp 1 and a serpentine-arranged capillary continuous flow reactor 2 .

[0038] The capillary continuous flow reactor is made of quartz glass, the inner diameter is 2mm, the wall thickness is 1mm, and the length is 2.26m.

[0039] The capillary continuous flow reactor channels are arranged in a serpentine pattern and placed in a single layer.

[0040] The high-power panel UV-LED lamp emits ultraviolet light with a characteristic wavelength of 365nm and a radiation window of 1200cm 2 , the input power is 500W, and the optical power is 165mW / cm 2 .

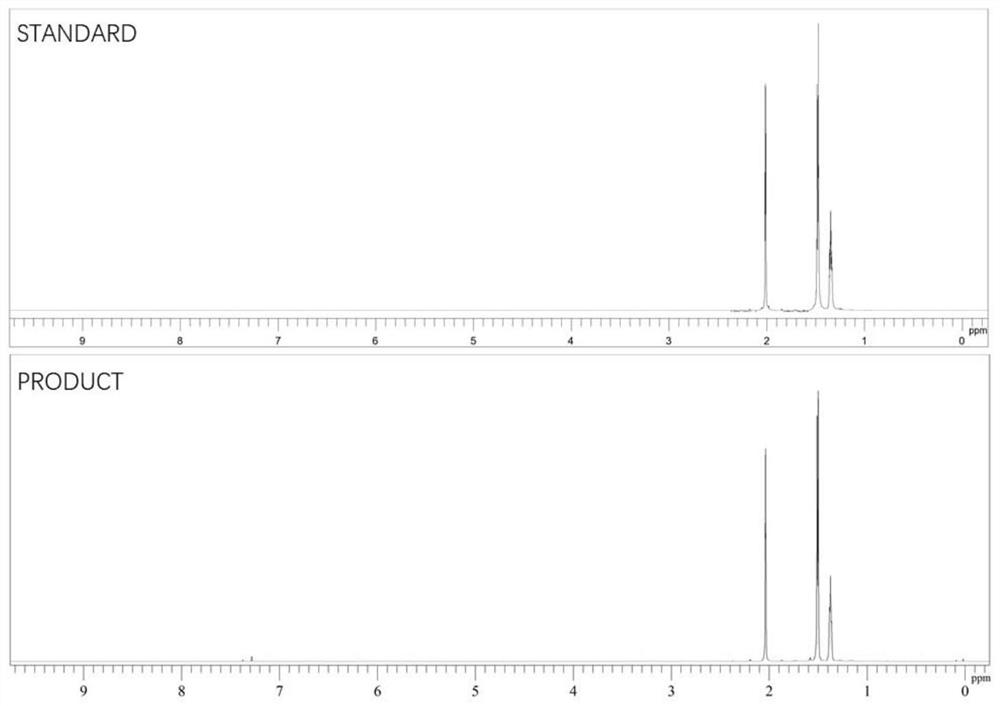

[0041] In this example, the above-mentioned system is used to carry out the photosensitized cycloaddition reaction of norbornadiene, the photosensitizer used is tetraethyl Michler's ketone, the mass fraction of the photosensitizer is 0.55%, there is no solvent, and the flow rate of the liquid phase in the capillary is 0.18ml / min, the reaction resi...

Embodiment 3

[0043] This embodiment includes: a high-power panel UV-LED lamp 1 , a continuous flow reactor 2 arranged in a serpentine shape, a laminated capillary tube 3 arranged in a serpentine shape, and a reflector 6 .

[0044] The capillary continuous flow reactor is made of quartz glass, the inner diameter is 2mm, the wall thickness is 1mm, and the length is 22.6m.

[0045] The channels of the capillary continuous flow reactor are arranged in a serpentine shape and are arranged in a stacked manner, and the number of stacked layers is 2.

[0046] The high-power panel UV-LED lamp emits ultraviolet light with a characteristic wavelength of 365nm and a radiation window of 1200cm 2 , the input power is 500W, and the optical power is 165mW / cm 2 .

[0047] A total reflector is placed under the high-power panel UV-LED lamp, and a capillary continuous flow reactor is placed between the high-power panel UV-LED lamp and the reflector.

[0048] In this example, the above-mentioned system is us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com