High-rate spherical hard carbon composite material and preparation method thereof

A composite material and high-magnification technology, which is applied to structural parts, electrical components, battery electrodes, etc., can solve the problems of low initial efficiency, material dynamic performance degradation, and dynamic performance degradation, achieving high lithium ion conductivity and improving Second-generation binding force, the effect of improving electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

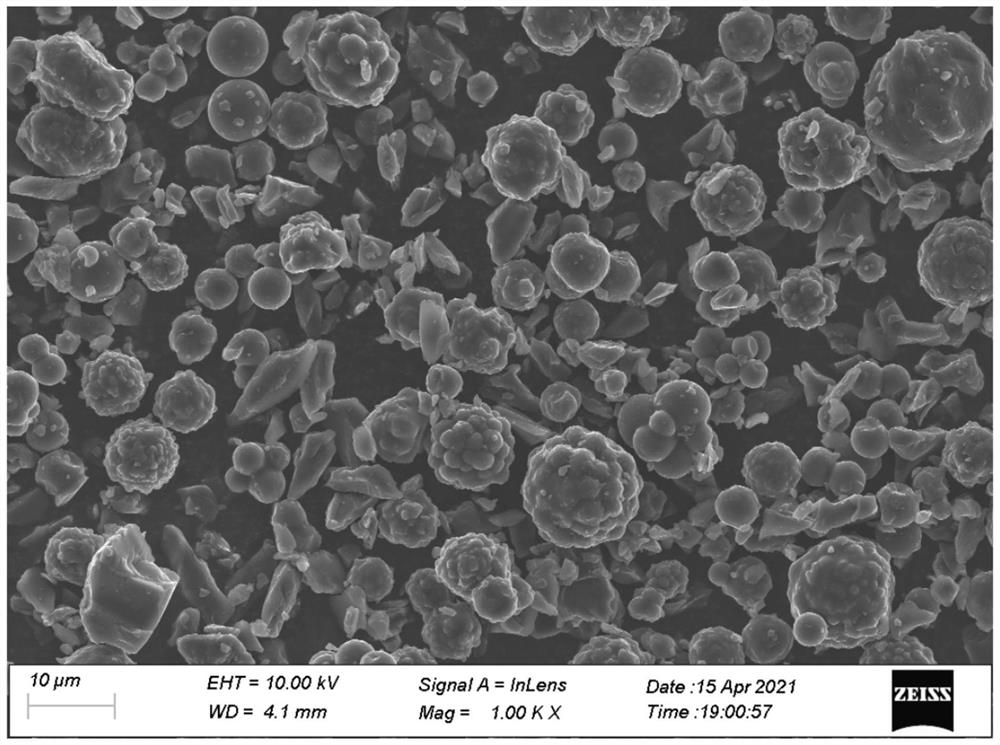

Image

Examples

preparation example Construction

[0026] The present invention also provides the preparation method of the high-rate spherical hard carbon composite material, comprising the following steps:

[0027] S1. After pulverizing the coconut shell, add terephthalaldehyde crosslinking agent, boric acid and a small amount of asphalt binder in an inert atmosphere of nitrogen and stirring speed, and heat up to 200-300 °C at a heating rate of 1-10 °C / min. ℃ reaction for 1 ~ 6h, cross-linking reaction occurs. After that, the nitrogen was stopped and changed to oxygen, and (NH) was added to the material system 4 ) 2 S 2 O 8 As an oxidant, the cross-linked oxidized resin was obtained by constant temperature reaction in an oxygen atmosphere for 2 hours; then transferred to a carbonization furnace, and under the protection of a fluorine gas nitrogen mixture (fluorine gas: nitrogen gas = 1:4), the temperature was 1 ~ 10 ° C The rate of / min was raised to 800~1200℃, kept for 1~6h, cooled to room temperature naturally, pulveri...

Embodiment 1

[0034] A preparation method of a high-rate spherical hard carbon composite material, comprising the following steps:

[0035] S1, after crushing 100g coconut shell, under the protection of nitrogen inert atmosphere, add 20g terephthalaldehyde crosslinking agent, 3g boric acid, 3g petroleum asphalt binder while stirring, and heat up to 5°C / min 250 ℃ reaction for 3h, cross-linking reaction occurs. Then stop nitrogen and change it to pass oxygen, and add 100ml, 1wt% (NH 4 ) 2 S 2 O 8 The solution was reacted at a constant temperature for 2 h in an oxygen atmosphere to obtain a cross-linked oxidized polymer. Then, the cross-linked oxidized polymer was transferred to a carbonization furnace, and under the protection of a fluorine gas nitrogen mixture (fluorine gas: nitrogen gas = 1:4), the temperature was raised to 900 °C at a rate of 5 °C / min for 3 hours. , naturally cooled to room temperature, and pulverized to obtain a high-magnification spherical secondary particle hard ca...

Embodiment 2

[0038] A preparation method of a high-rate spherical hard carbon composite material, comprising the following steps:

[0039] S1, after crushing 100g coconut shells, add 10g terephthalaldehyde crosslinking agent, 1g boric acid, 1g petroleum asphalt binder under nitrogen inert atmosphere and stirring speed, and heat up to 200°C at a heating rate of 1°C / min After 6h of reaction, a cross-linking reaction occurred. Then stop nitrogen and change it to oxygen, and add 100ml, 0.5wt% (NH 4 ) 2 S 2 O 8 The solution was reacted at a constant temperature for 2 h in an oxygen atmosphere to obtain a cross-linked oxidized polymer. Then, the cross-linked oxidized polymer was transferred to a carbonization furnace, and under the protection of a fluorine gas nitrogen mixture (fluorine gas: nitrogen gas = 1:4), the temperature was raised to 800 °C at a rate of 1 °C / min for 6 h. , naturally cooled to room temperature, and pulverized to obtain a high-magnification spherical secondary particl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com