High-performance carbon nitrogen compound/polyoxometallate composite material electrochromic device

A polyoxometalate, electrochromic device technology, applied in instruments, nonlinear optics, optics, etc., to achieve the effects of easy operation, reduced voltage range, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

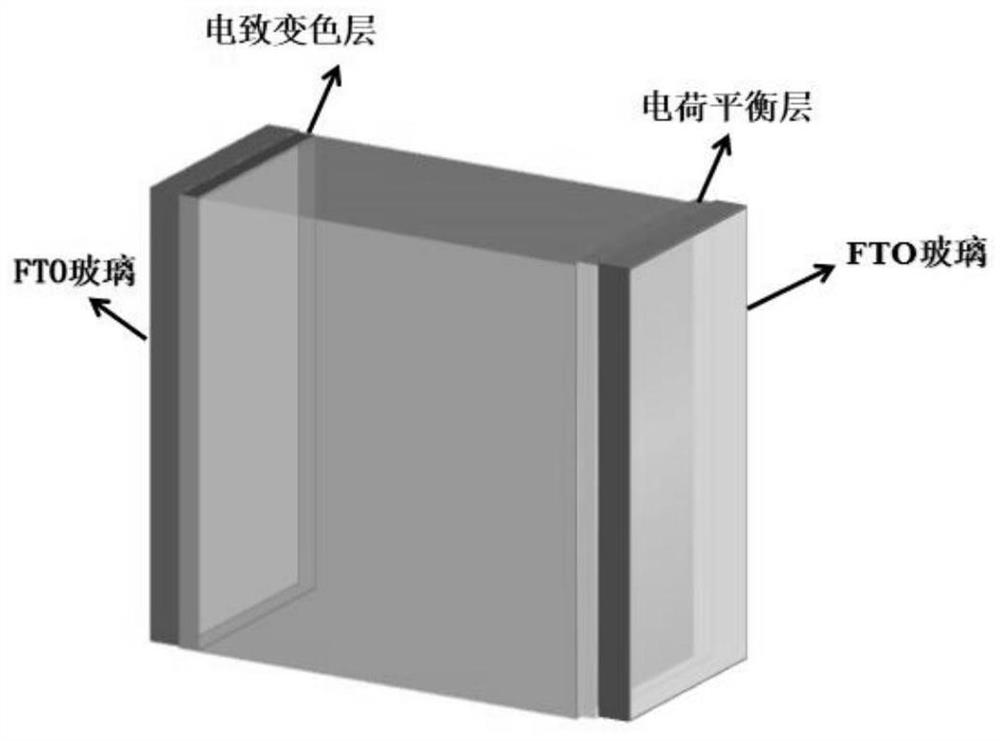

[0027] Example 1 High-performance carbonitride / polyoxometalate composite electrochromic device

[0028] (1) The preparation method is as follows

[0029] 1. Preparation of working electrode

[0030] ①Carbonitride Ti 3 C 2 T X Preparation of MXenes

[0031] 1 g of lithium fluoride (LiF, AR) was added to 10 mL of hydrochloric acid (HCl, 86%), and after stirring at 35 °C for 5 min, 0.5 g of Ti was slowly added3 AlC 2 powder, and continued stirring at 35°C for 24h. After the reaction, the product was centrifuged and washed with deionized water until the pH was 6, centrifuged and washed, the obtained precipitate was dissolved in 10 mL of deionized water, sonicated for 10 min, and the obtained suspension was centrifuged at 2000 rpm for 10 min to obtain Ti. 3 C 2 T X MXene solution with a concentration of 3.2 g / mL and an average flake size of 1 μm.

[0032] ②Keggin type polyacid K 6 [α-P 2 W 18 O 62 ]·14H 2 O(P 2 W 18 ) preparation

[0033] 30g Na 2 WO 4 ·2H 2 O...

Embodiment 2

[0047] Example 2 High-performance carbonitride / polyoxometalate composite electrochromic device

[0048] (1) The preparation method is as follows

[0049] 1. Preparation of working electrode

[0050] ①Carbonitride Ti 3 C 2 T X Preparation of MXenes

[0051] Same as Example 1

[0052] ②Keggin type polyacid K 6 [α-P 2 W 18 O 62 ]·14H 2 O(P 2 W 18 ) preparation

[0053] Same as Example 1

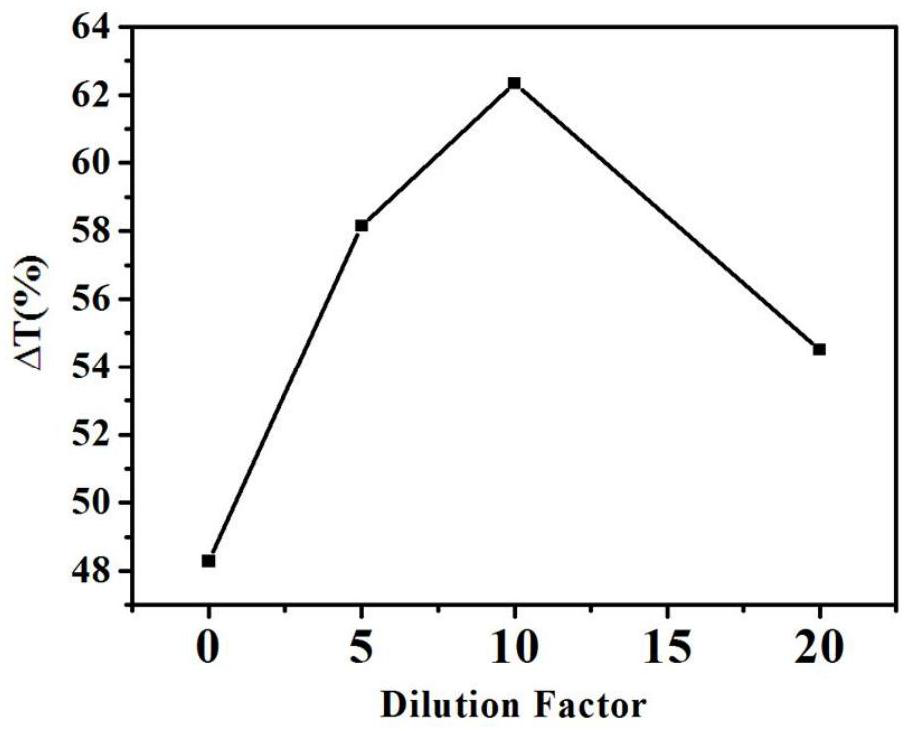

[0054] ③Ti 3 C 2 T X / P 2 W 18 Preparation of composite membranes

[0055] Add polyvinyl alcohol (PVA) powder into deionized water at a ratio of 5 mg:100 mL of material to liquid, and stir magnetically at 120° C. until PVA is completely dissolved in water to obtain a PVA crosslinking agent solution.

[0056] Ti 3 C 2 T X The MXene solution (3.2 g / mL) was placed in a cell crusher in an ice-water bath, and sonicated at 300 W for 30 min. Ti before and after crushing 3 C 2 T X The MXene solutions were named MX S and MX WS, respectively.

[0057] Take 2g P 2 W 18 Powd...

Embodiment 3

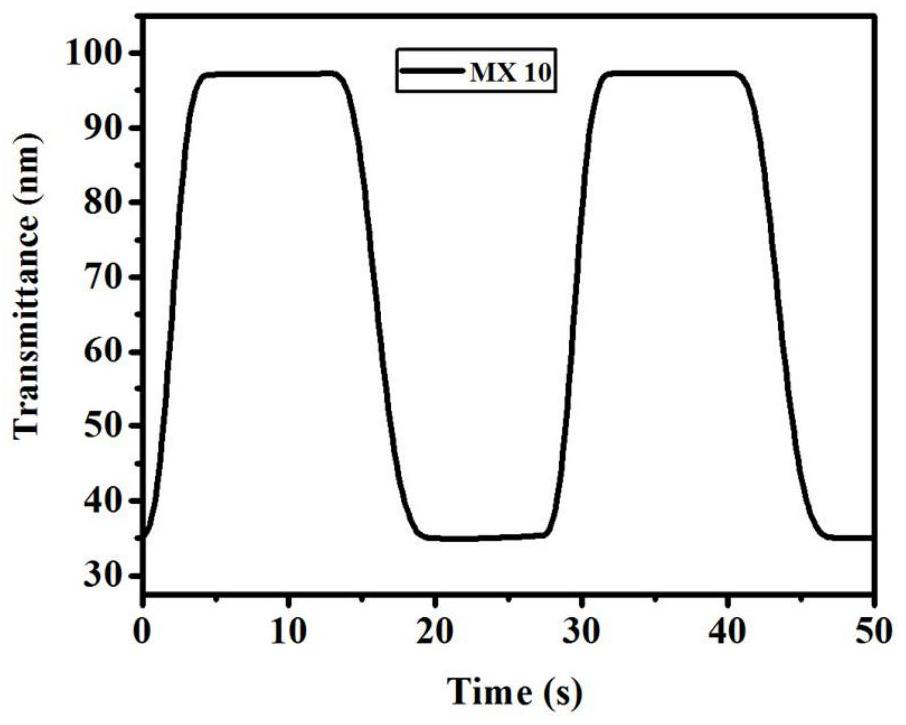

[0066] The prepared MX S / P 2 W 18 The working electrode of the composite film device or the MX WS / P2W18 composite film device is the positive electrode, and the counter electrode is the negative electrode for testing. The applied voltage is 1.5~-1.5V, the period is 50s, and the positive voltage and negative voltage are applied for the same time. In-meter test at 576nm with MX S / P 2 W 18 Composite film, MX WS / P 2 W 18 The charge-discharge curves of the device prepared with the composite film as the working electrode are as follows: Figure 3b shown. Depend on Figure 3b Visible, MX S / P 2 W 18 The charge-discharge curve of the composite film device is larger than that of the MX WS / P2W18 composite film device, which indicates that the MX S / P 2 W 18 The mass specific capacitance of the composite film device is higher, the calculated MX S / P 2 W 18 The mass specific capacitance of the composite membrane device is 5F / g. Ti used in this device 3 C 2 T X / P 2 W 18 The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coloring time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com