Testing method of woven composite material blade

A technology of composite materials and testing methods, which is applied in the direction of testing the strength of materials by applying a stable bending force, which can solve the problems of different structures and the inability to measure the compressive properties of woven composite material blades.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

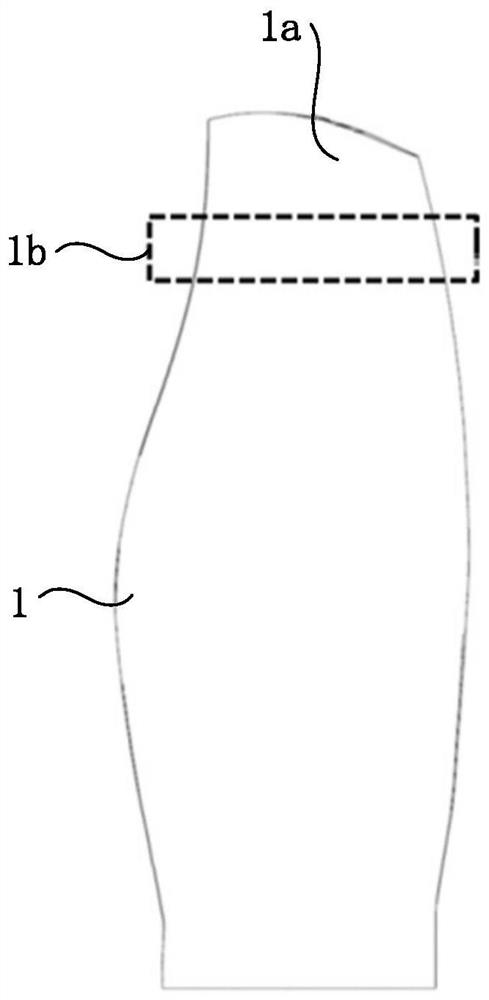

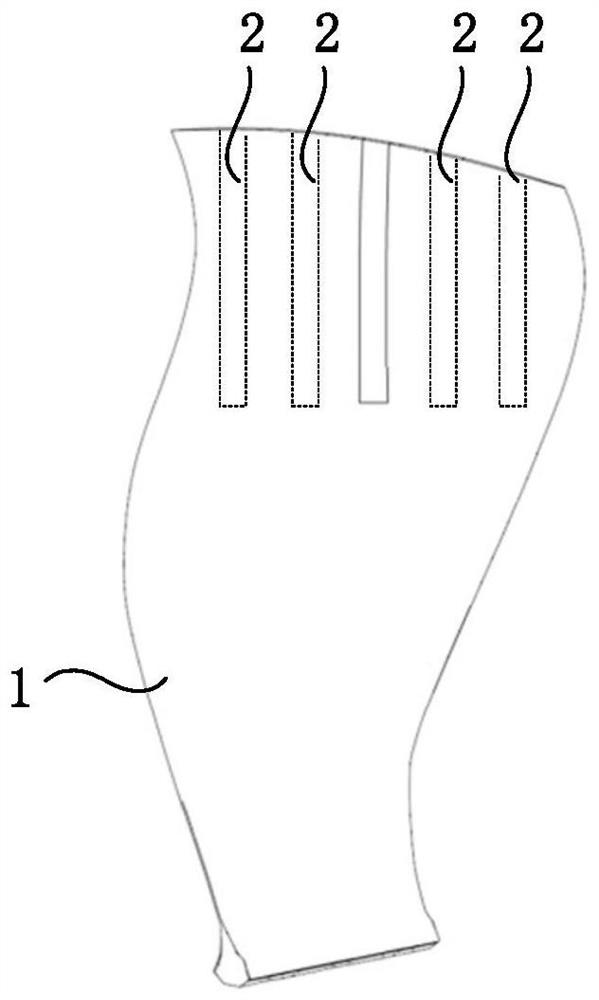

[0036] Combine below Figure 1 to Figure 6 The technical solutions provided by the present invention are described in more detail.

[0037] The embodiment of the present invention provides a testing method for a woven composite material blade, which is used for testing an actual woven composite material blade 1 . The method includes the following steps:

[0038] Step S100 , setting a target area on the woven composite material blade 1 .

[0039] The woven composite blade 1 is an actual manufactured blade to be used on an aeroengine. It is not a sample manufactured for testing, so the woven composite blade 1 can reflect all the structural characteristics of the blade, and can reflect the compressive performance of the woven composite material caused by the blade profile distortion, thickness and other structural characteristics during the manufacturing process. Impact. It can be seen that the woven composite material blade 1 can be used to test its compression performance u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com