Drilling, punching and protecting integrated system and method

A technology of drilling punching and subsystems, which is applied in the direction of drilling equipment and methods, drilling tools, mining fluids, etc., which can solve the problems of coal fragmentation, easy collapse of drilling holes, lack of pertinence, etc., and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

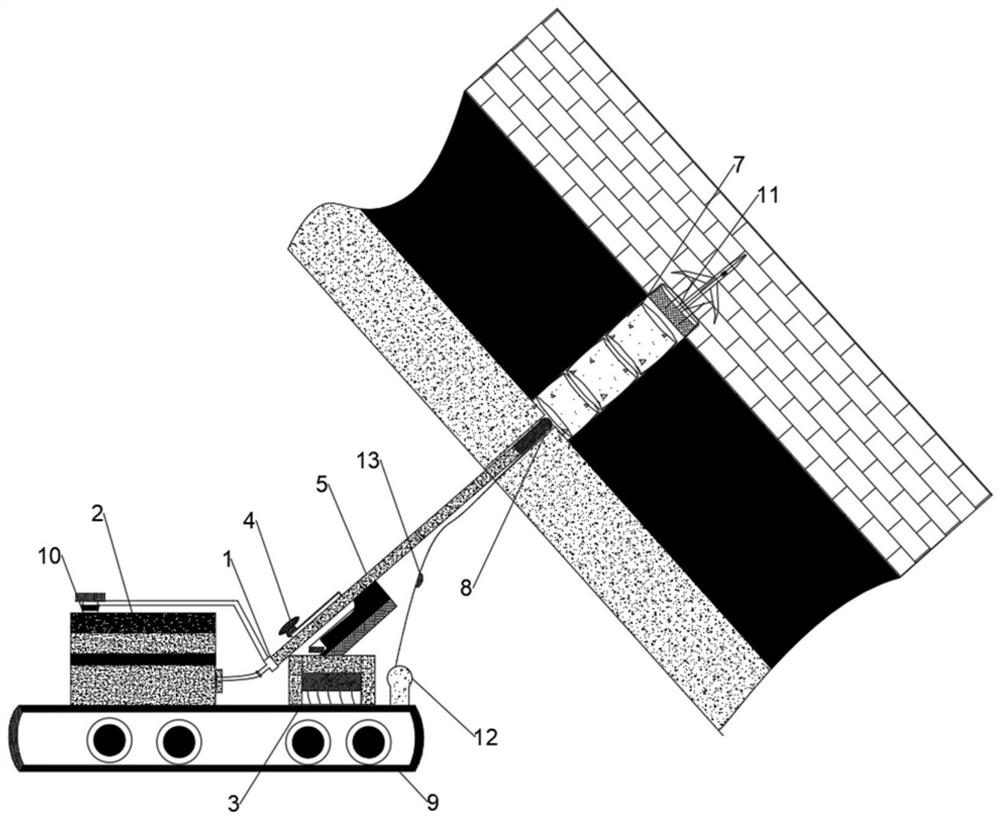

[0020] In view of the characteristics of complex geological structure and low permeability of broken and soft coal seams, large drilling deformation, and easy instability of the hole wall under the action of in-situ stress, gas pressure, tectonic stress and other factors, this embodiment provides a drilling punch Protection integrated system, including hydraulic punching tool subsystem and hole protection subsystem.

[0021] The hydraulic punching tool subsystem includes a high pressure water braid 1 , a water tank 2 , an emulsification pump station 3 , a pressure relief valve 4 , a sealed drill pipe 5 , a high pressure hose 6 , a drill bit 8 , a drilling rig 9 and a flow meter 10 .

[0022] The sealed drill rod 5 is a hollow circular tube as a whole. The drill bit 8 is provided with an axial nozzle for ejecting high-pressure water. The drill bit 8 is installed at the head end of the sealed drill rod 5 . The central hole of the drill bit 8 communicates with the inner cavity ...

Embodiment 2

[0028] This embodiment provides an integrated method for drilling, flushing and protection using the system described in Embodiment 1, including the following steps:

[0029] a. Install the system and ground lines and inspect them.

[0030] b. Drilling construction. The drilling rig is transported to the preset position according to the selected location of the construction plan, and the drilling construction starts.

[0031] c. After the drilling is formed, exit the drilling tool, move the power head forward, connect the high-pressure water braid 1, install the special punching bit 8 on the drill pipe, and push the drilling again.

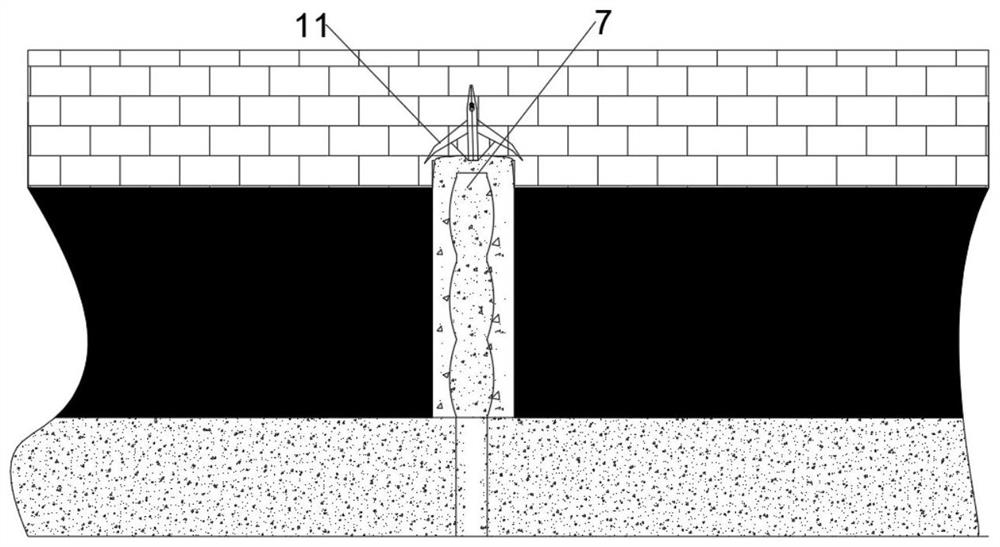

[0032] d. The front end fixing device 11 protrudes from the central hole of the drill bit 8 . The supporting claws are deployed and embedded in the coal seam on the inner wall of the borehole. At the same time, the pocket 7 embedded on the outside of the drill pipe is pushed into the hole in the coal seam with a push rod.

[0033] e. Turn on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com