Method for recovering and preparing dabigatran etexilate mesylate from production mother liquor

A technology of dabigatran etexilate mesylate and dabigatran etexilate, which is applied in the field of preparing dabigatran etexilate mesylate, can solve problems such as difficult to purify dabigatran etexilate products and many impurities, and achieve Fewer types of solvents, reduced waste emissions, and milder reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

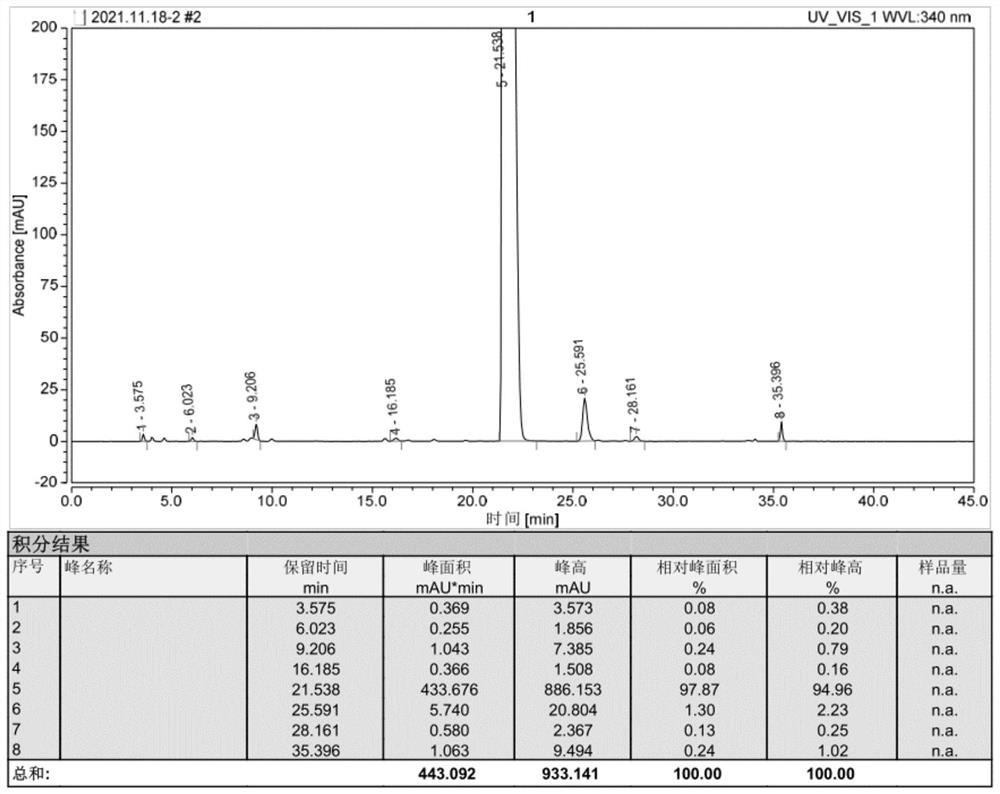

[0061] Get dabigatran etexilate mesylate and concentrate to dryness under reduced pressure at 50 ° C of the mother liquor, get 50 g of evaporated dry matter (its HPLC spectrogram is as follows: figure 1 shown), put it into a 1000ml three-necked flask, add 300g of acetonitrile, stir and heat up to 55-60°C. Adjust the pH of the system to 8 with ammonia water, keep stirring for 1 hour, slowly add 150 g of purified water, continue to keep stirring for 30 minutes after adding water, and cool down. The crystals were crystallized for 4 hours, filtered and dried to obtain 35 g of dabigatran etexilate free base.

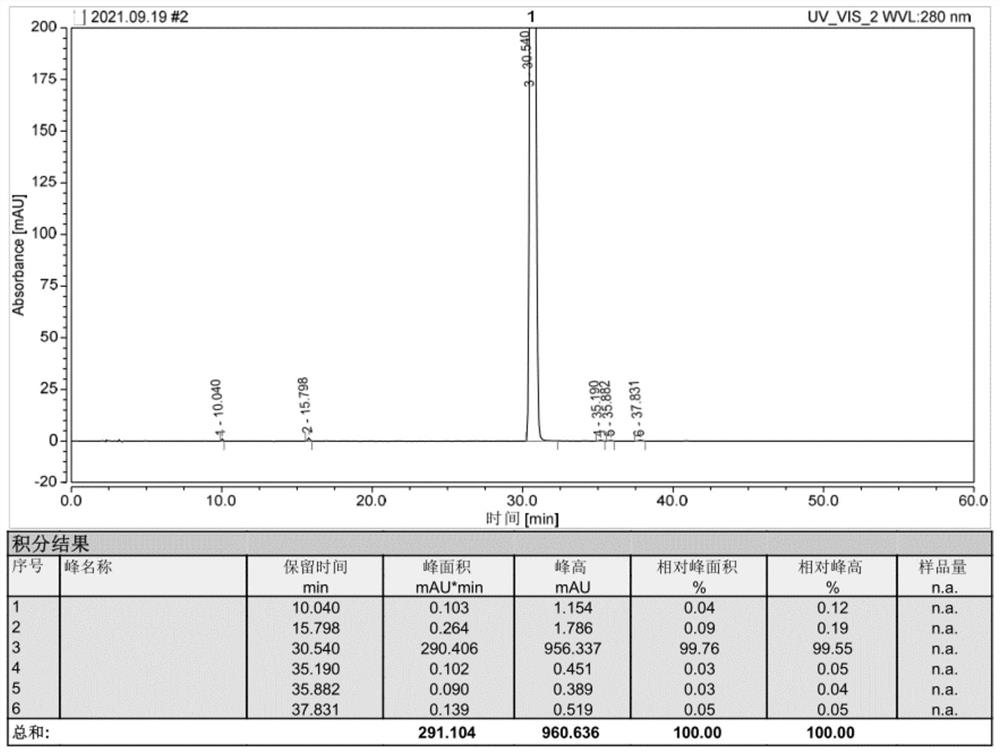

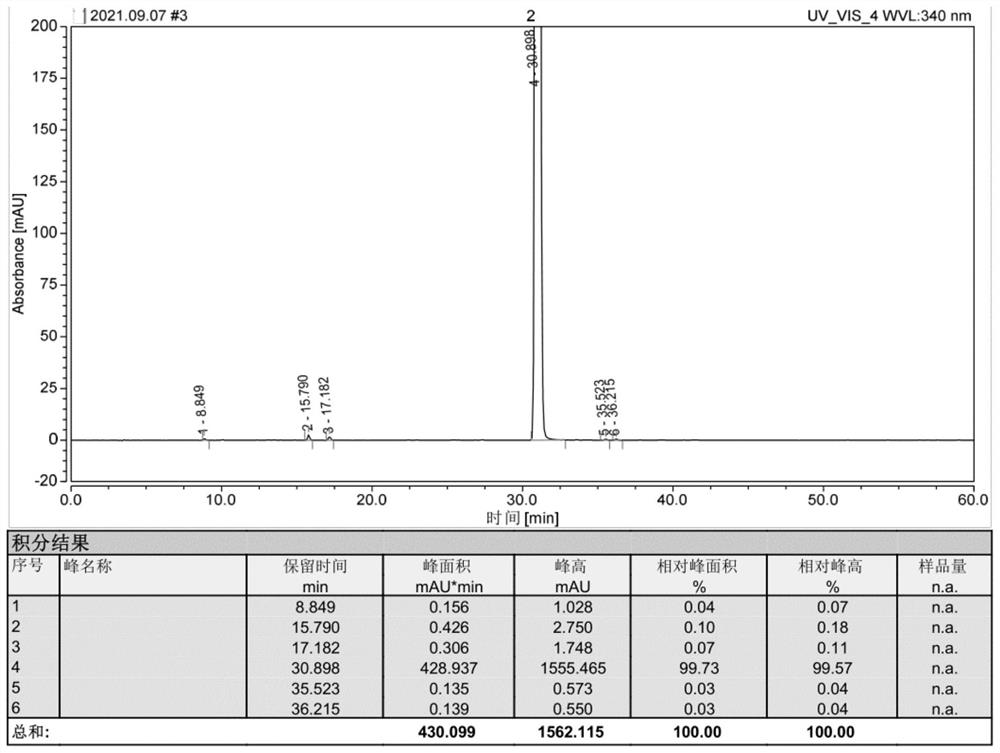

[0062] Put 35g of dabigatran etexilate free base into a 500ml three-necked bottle, add 210g of ethyl acetate, stir and heat up to dissolve until the solution is clear, the temperature of the solution is 55-60°C, keep stirring for 30min, stop heating, cool down naturally, and observe crystal precipitation. After that, the temperature at the time of crystal precipitation was m...

Embodiment 2

[0066] Get dabigatran etexilate mesylate and concentrate to dryness under reduced pressure at 50 ° C of the mother liquor, get 50 g of evaporated dry matter (its HPLC spectrogram is as follows: figure 1 shown), put it into a 1000ml three-necked flask, add 350g of acetonitrile, stir and heat up to 55-60°C. Adjust the pH of the system to 8 with triethylamine, keep stirring for 1 hour, slowly add 180 g of purified water, continue to keep stirring for 30 minutes after adding water, and cool down. , crystallized for 5 hours, filtered, and dried to obtain 34.6 g of dabigatran etexilate free base.

[0067] Put 34.6g of dabigatran etexilate free base into a 500ml three-necked flask, add 230g of ethyl acetate, stir and heat up to dissolve until the solution is clear, the temperature of the solution is 55-60°C, keep stirring for 30min, stop heating, cool down naturally, and observe the crystals. After the precipitation, the temperature at the time of crystal precipitation was maintaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com