Carbon dioxide refrigerating unit for artificial stratum freezing system

A carbon dioxide and formation technology, applied in refrigerators, refrigeration components, irreversible cycle compressors, etc., can solve the problems of compressor hazards, inability to adapt to changes in volume ratio, adverse effects of carbon dioxide cooling effects, etc., to solve the problem of lubrication. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described below with reference to the embodiments and the accompanying drawings. The examples are only used to explain the present invention, and are not intended to limit the scope of the claimed protection of the present invention.

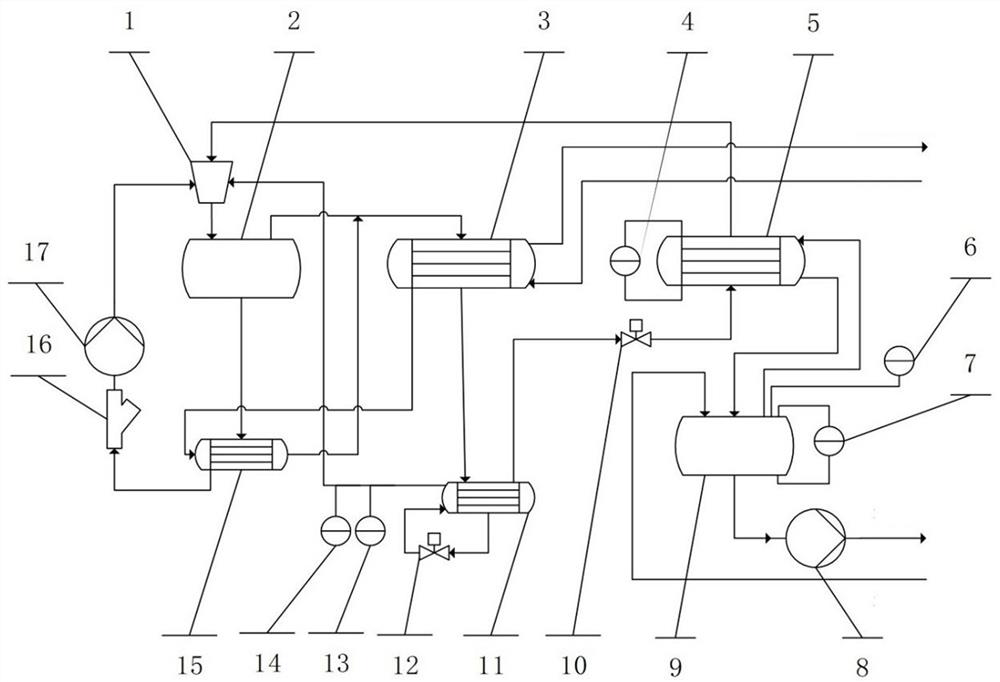

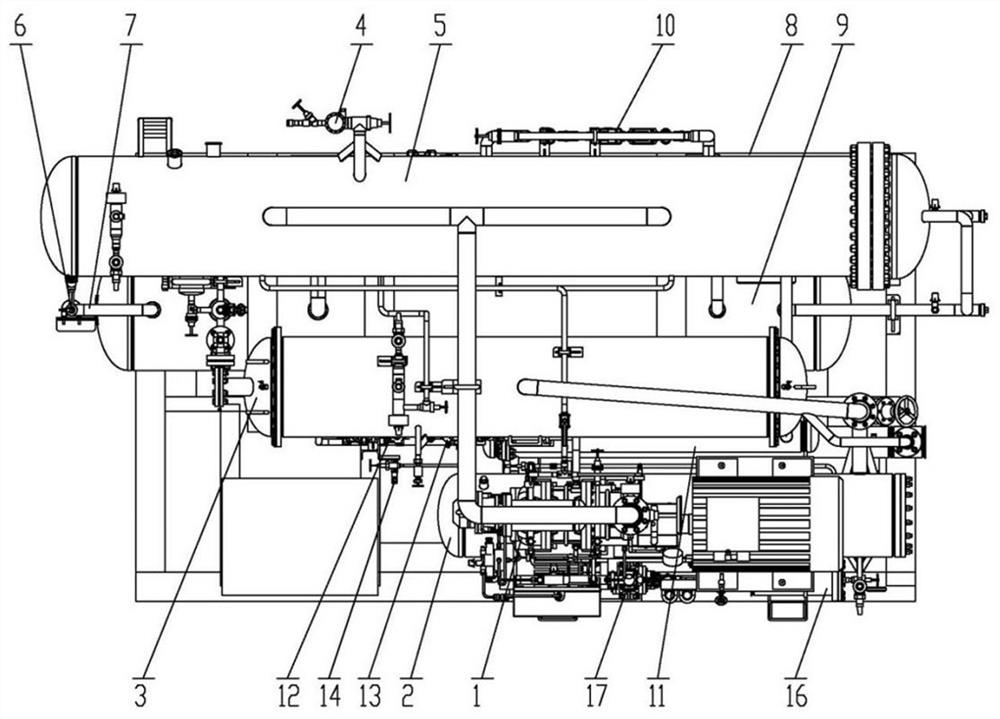

[0026] like figure 1 and figure 2 , a carbon dioxide carrier cooling unit for artificial formation freezing system, the cooling unit includes a single-stage screw compressor 1, an oil separator 2, a liquid-cooled oil cooler 15, an oil filter 16, and a lubricating oil pump 17, Economizer 11 , water-cooled condenser 3 , condensation evaporator 5 , carbon dioxide accumulator 9 , carbon dioxide shield pump 8 .

[0027] Lubricating oil side: The oil phase outlet of the oil separator 2 is connected to the shell side inlet of the liquid-cooled oil cooler 15 through a pipeline, the shell side outlet of the liquid-cooled oil cooler 15 is connected to the inlet of the oil filter 16, and the outlet of the oil filter 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com