Interior wall inorganic coating prepared from organic-inorganic composite emulsion and preparation method of interior wall inorganic coating

An inorganic composite and inorganic coating technology, which is applied in the direction of fireproof coatings, antifouling/underwater coatings, alkali metal silicate coatings, etc., can solve the problems of poor storage stability and difficult quality control of inorganic coatings, and achieve stable and high chemical properties , fine manufacturing process, the effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

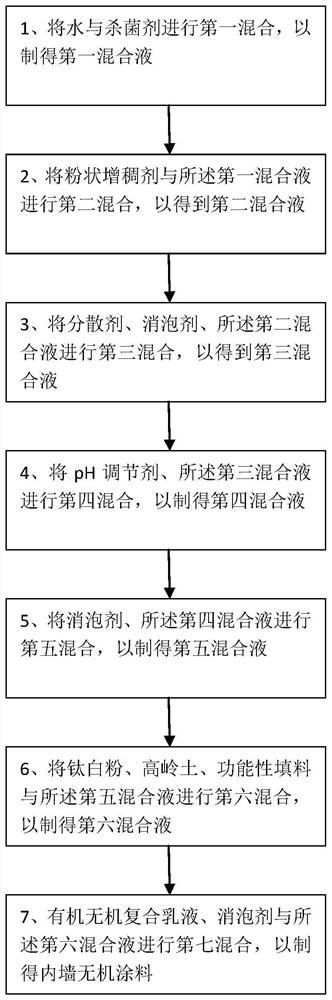

[0067] The present invention also provides a method for preparing an inorganic coating for interior walls made of the above-mentioned organic-inorganic composite emulsion, characterized in that it includes the following steps:

[0068] S100, first mixing water and bactericide to obtain a first mixed solution;

[0069] S200, carrying out the second mixing of the powdery thickener and the first mixed solution to obtain the second mixed solution;

[0070] S300, performing a third mixing of the dispersant, the defoaming agent, and the second mixed solution to obtain a third mixed solution;

[0071] S400, performing a fourth mixing with the pH regulator and the third mixed solution to obtain a fourth mixed solution;

[0072] S500, carrying out the fifth mixing of the defoaming agent and the fourth mixed solution to obtain the fifth mixed solution;

[0073] S600, carrying out sixth mixing of titanium dioxide, kaolin, functional filler and the fifth mixed solution to obtain a sixth...

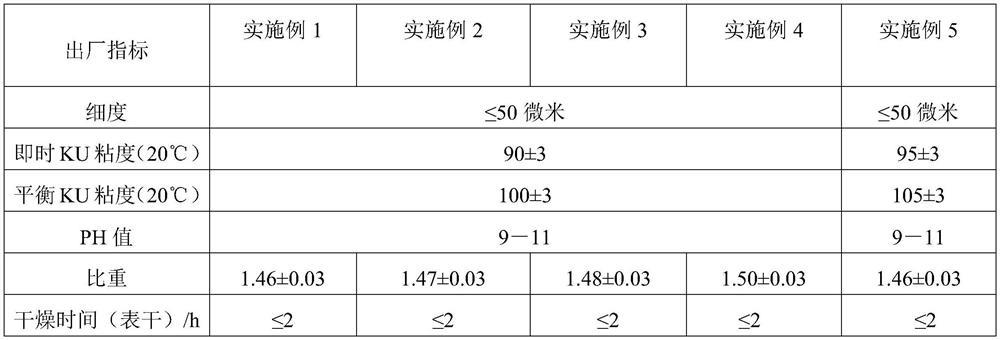

Embodiment 1

[0086] A raw material preparation (total 100g): water 18g, powdery thickener 0.2g, bactericide 0.1g, dispersant 0.4g, wetting agent 0.1g, defoamer 0.7g, pH adjuster 0.1g, titanium dioxide 20g, 3g kaolin, 22.4g functional filler, 35g organic-inorganic composite emulsion.

[0087] B. Preparation of inorganic coatings for interior walls:

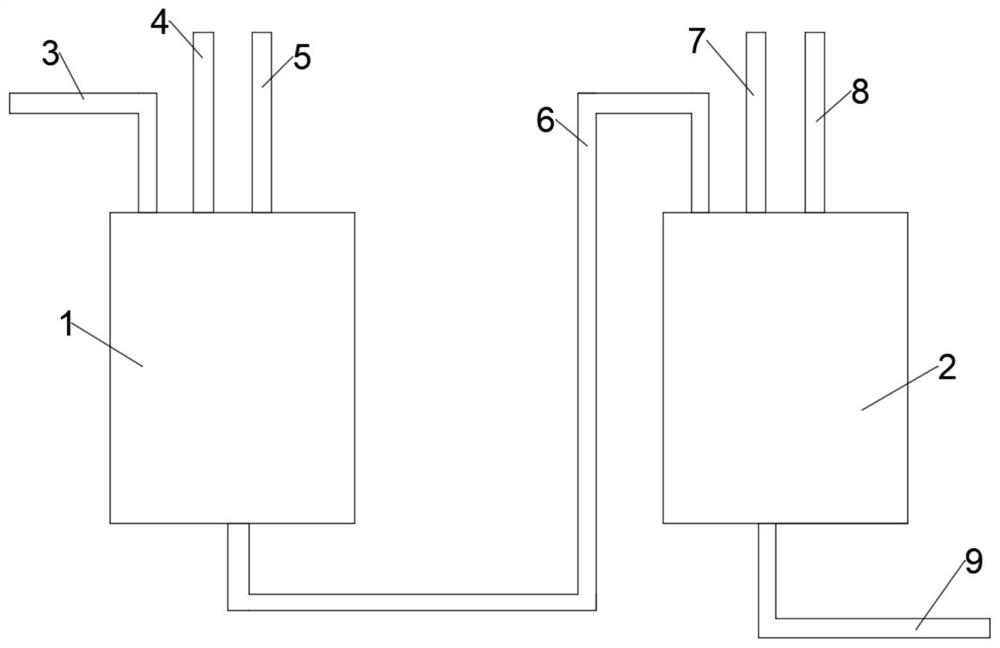

[0088] 1) Use deionized water for high-speed dispersion kettle 1, low-speed paint-adjusting kettle 2, powder transportation pipeline 3, water transportation pipeline 4, high-speed dispersion process liquid auxiliary raw material transportation pipeline 5, water slurry delivery pipeline 6, The liquid raw material conveying pipeline 7, the organic-inorganic composite emulsion conveying pipeline 8, and the finished product unpacking pipeline 9 in the paint mixing process are cleaned up, and the excess polyvalent ion impurities are taken out;

[0089] 2) Add deionized water to the high-speed dispersing kettle 1 through the water delivery pipeline ...

Embodiment 2

[0097] A raw material preparation (total 100g): water 25g, powdery thickener 0.5g, bactericide 0.15g, dispersant 0.6g, wetting agent 0.15g, defoamer 0.45g, pH adjuster 0.15g, titanium dioxide 15g, 5g kaolin, 28g functional filler, 25g organic-inorganic composite emulsion.

[0098] B. Preparation of inorganic coatings for interior walls:

[0099]1) Use deionized water for high-speed dispersion kettle 1, low-speed paint-adjusting kettle 2, powder transportation pipeline 3, water transportation pipeline 4, high-speed dispersion process liquid auxiliary raw material transportation pipeline 5, water slurry delivery pipeline 6, The liquid raw material conveying pipeline 7, the organic-inorganic composite emulsion conveying pipeline 8, and the finished product unpacking pipeline 9 in the paint mixing process are cleaned up, and the excess polyvalent ion impurities are taken out;

[0100] 2) Add deionized water to the high-speed dispersing kettle 1 through the water delivery pipeline...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com