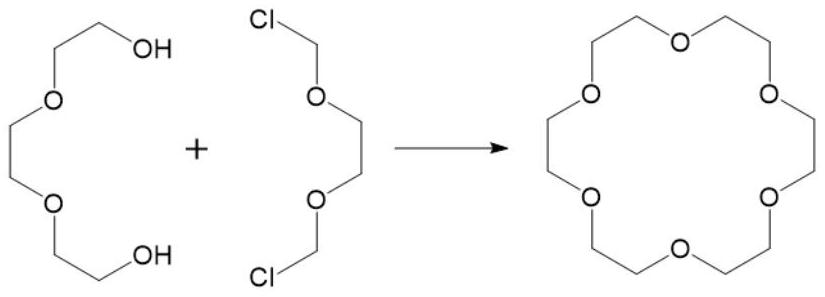

Method for preparing aliphatic crown ether from ethylene oxide through oligomerization

A technology of ethylene oxide and aliphatic, which is applied in the field of preparation of aliphatic crown ether by oligomerization of ethylene oxide, which can solve the problems of high market price, need for batch operation, and large equipment occupation, so as to broaden the range of catalysts Types and proportions, reducing equipment material requirements, and avoiding the effect of recycling problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

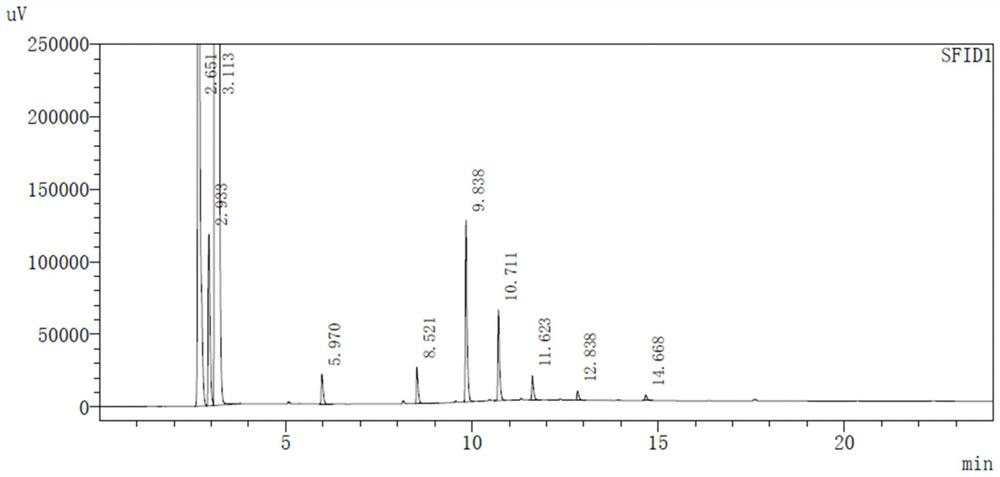

Embodiment 1

[0055] Embodiment 1: a kind of boron trifluoride catalyzes the method for oligomerization of ethylene oxide into aliphatic crown ether, carries out according to the following steps:

[0056] (1) Preparation of polymerization raw materials:

[0057] Monomer solution: A 500 mL volume steel cylinder was charged with 86.3 g (100 mL) of commercially available ethylene oxide. 258.9g (393mL) of commercially available pressurized liquefied dimethyl ether is stored in a steel cylinder, the outlet of the steel cylinder is connected to a coil, cooled to below -30°C in a -40°C ethanol cooling bath, and then filled with the aforementioned The steel cylinder forms a solution, which is used as a monomer solution after shaking.

[0058] Catalyst solution: 9.0 g (8 mL) of a commercially available boron trifluoride ether solution (weight ratio 1:1.04) was poured into a 100 mL volume cylinder. 81.0g (88mL) of commercially available pressurized liquefied dimethyl ether is stored in a steel cylind...

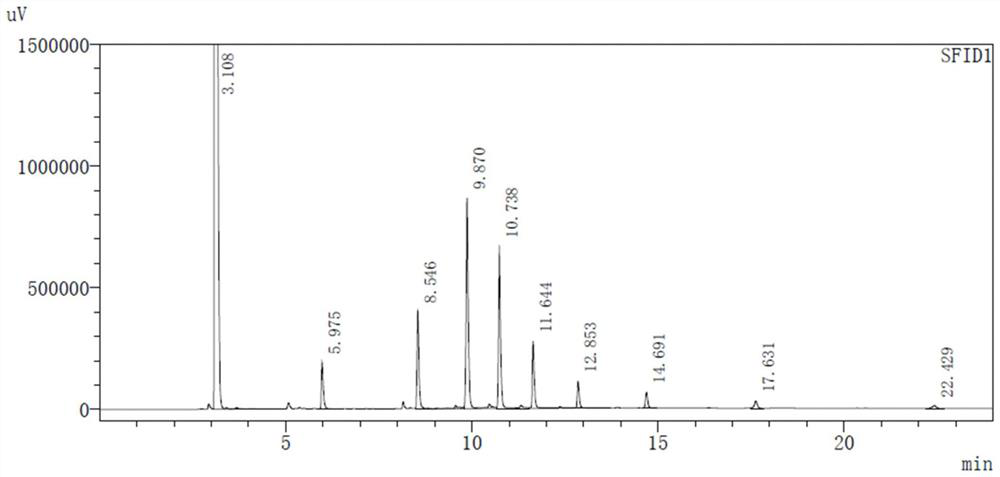

Embodiment 2

[0065] Embodiment 2: a kind of method that aluminum trichloride catalyzes ethylene oxide oligomerization into aliphatic crown ether, carries out according to the following steps:

[0066] (1) Preparation of polymerization raw materials:

[0067] Monomer solution: A 500 mL volume steel cylinder was charged with 86.3 g (100 mL) of commercially available ethylene oxide. 345.2g (375mL) of commercially available pressurized liquefied methyl chloride is stored in a steel cylinder, the outlet of the cylinder is connected to a coil, cooled to 0°C in a -20°C ethanol cold bath, and then filled into the aforementioned steel cylinder containing ethylene oxide to form a solution , shake well and use it as a monomer solution for later use.

[0068] Catalyst solution: 1.0 g of commercially available anhydrous aluminum trichloride powder and 1.0 g of deionized water were injected into a steel cylinder with a volume of 100 mL. 54.0g (82mL) of commercially available pressurized liquefied meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com