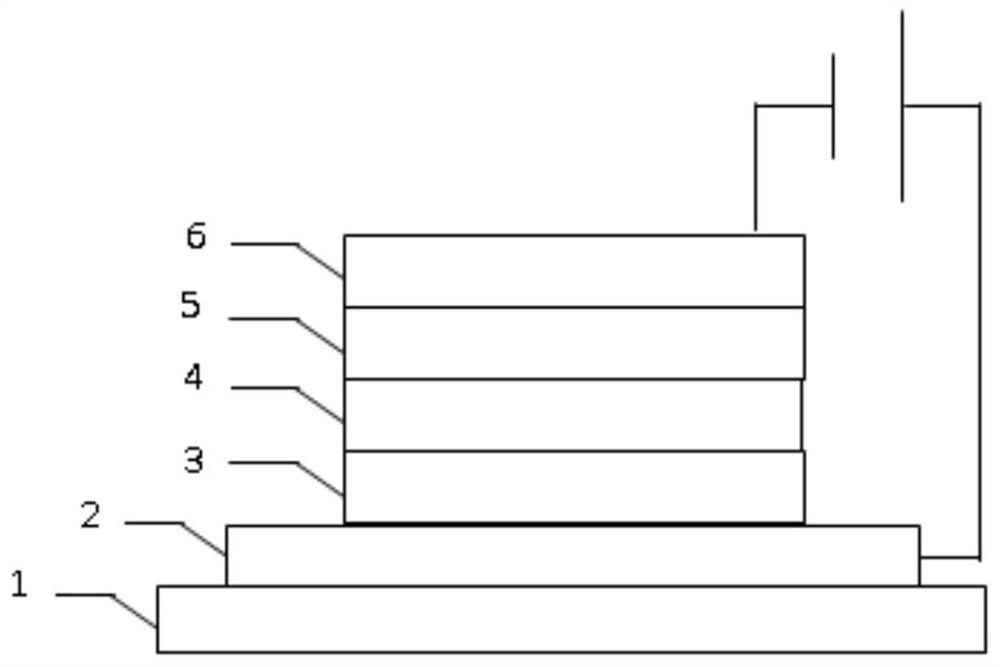

Composite material, quantum dot light emitting diode and preparation method of quantum dot light emitting diode

A composite material and electron track technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problem of low carrier transmission efficiency, achieve the effects of improving luminous efficiency, avoiding agglomeration, and improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0104] FeN in this example 4 The preparation steps of the composite material compounded with ZnO are as follows:

[0105] 1), first add an appropriate amount of zinc acetate into 50ml of ethanol to form a solution with a total concentration of 0.5M. Then stir and dissolve at 70 ° C, add the lye (molar ratio, OH) prepared by dissolving potassium hydroxide in 10 ml of ethanol - : Zn 2+ =2:1, pH=12). Continue to stir at 70 °C for 4 h to obtain a homogeneous transparent solution. Subsequently, after the solution was cooled, it was precipitated with ethyl acetate, and after centrifugation, it was dissolved with a small amount of ethanol, and the steps of precipitation and dissolution were repeated 3 times, and dried to obtain ZnO nanoparticles;

[0106] 2), the appropriate amount of FeCl 3and ammonium chloride were dissolved in 10 ml of dimethyl sulfoxide (molar ratio, Fe:N=1:5), after ultrasonic dissolution, the mixed solution was transferred to a high-pressure high-temperatu...

Embodiment 2

[0109] In this example, MnN 4 with TiO 2 The preparation steps of the composite composite material are as follows:

[0110] 1) First, add an appropriate amount of titanium nitrate into 50ml of methanol to form a solution with a total concentration of 0.8M. Then stir and dissolve at 60°C, add sodium hydroxide dissolved in 10ml methanol solution (molar ratio, OH - : Ti 4+ = 2.5:1). Continue stirring at 60°C for 4h to obtain a homogeneous solution. Then, after the solution was cooled, it was precipitated with ethyl acetate, and after centrifugation, it was dissolved with a small amount of methanol, and the steps of precipitation and dissolution were repeated 3 times, and then dried to obtain TiO 2 Nanoparticles;

[0111] 2), the appropriate amount of MnCl 2 and urea were dissolved in 10 mL of N,N-dimethylformamide (molar ratio, Mn:N=1:6), after ultrasonic dissolution, the mixed solution was transferred to a high-pressure high-temperature reaction kettle. First, apply a hi...

Embodiment 3

[0114] CoN in this embodiment 4 The preparation steps of the composite material compounded with NiO are as follows:

[0115] 1), first add an appropriate amount of nickel chloride to 50ml of propanol to form a solution with a total concentration of 1M. Then stir and dissolve at 80 ° C, add the alkaline solution (molar ratio, OH) prepared by dissolving lithium hydroxide in 10 ml propanol. - : Ni 2+ =2:1, pH=12). Continue to stir at 80°C for 4h to obtain a homogeneous solution. Subsequently, after the solution was cooled, it was precipitated with ethyl acetate, and after centrifugation, it was dissolved with a small amount of ethanol, and the steps of precipitation and dissolution were repeated 3 times, and dried to obtain NiO nanoparticles;

[0116] 2), the appropriate amount of CoCl 2 and urea were dissolved in 10 mL of tetrahydrofuran (molar ratio, Co:N=1:7), after ultrasonic dissolution, the mixed solution was transferred to a high-pressure high-temperature reaction ket...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com