Light-emitting device and preparation method thereof

A technology for light-emitting devices and quantum dots to emit light, which is applied in the manufacture of semiconductor/solid-state devices, semiconductor devices, and electric solid-state devices, etc. It can solve problems affecting electron injection efficiency, charge accumulation, poor interface fusion, etc. Interface gap optimization, good interface bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

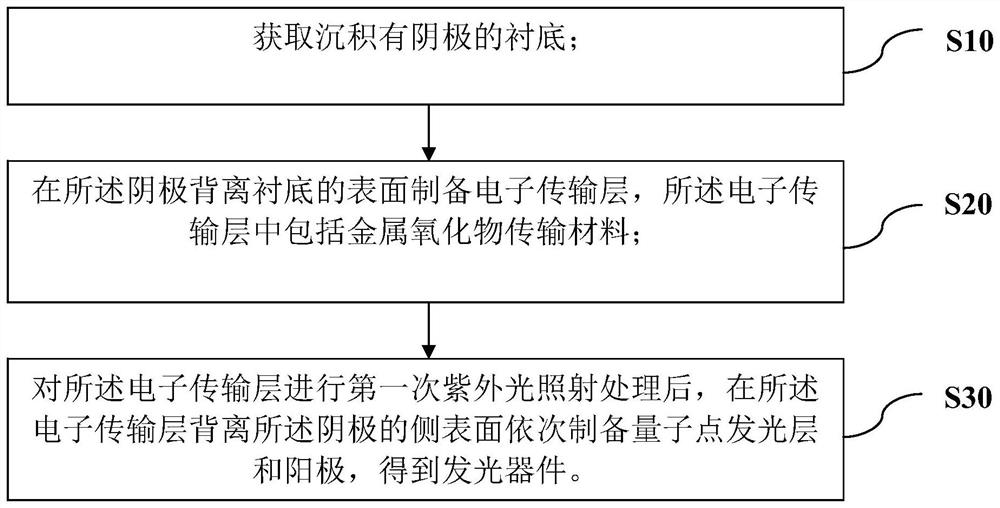

[0023] as attached figure 1 As shown, the first aspect of the embodiments of the present application provides a method for preparing a light-emitting device, including the following steps:

[0024] S10. Obtain the substrate on which the cathode is deposited;

[0025] S20. Prepare an electron transport layer on the surface of the cathode away from the substrate, and the electron transport layer includes a metal oxide transport material;

[0026] S30. After the first ultraviolet light irradiation treatment is performed on the electron transport layer, a quantum dot light-emitting layer and an anode are sequentially prepared on the side surface of the electron transport layer away from the cathode to obtain a light-emitting device.

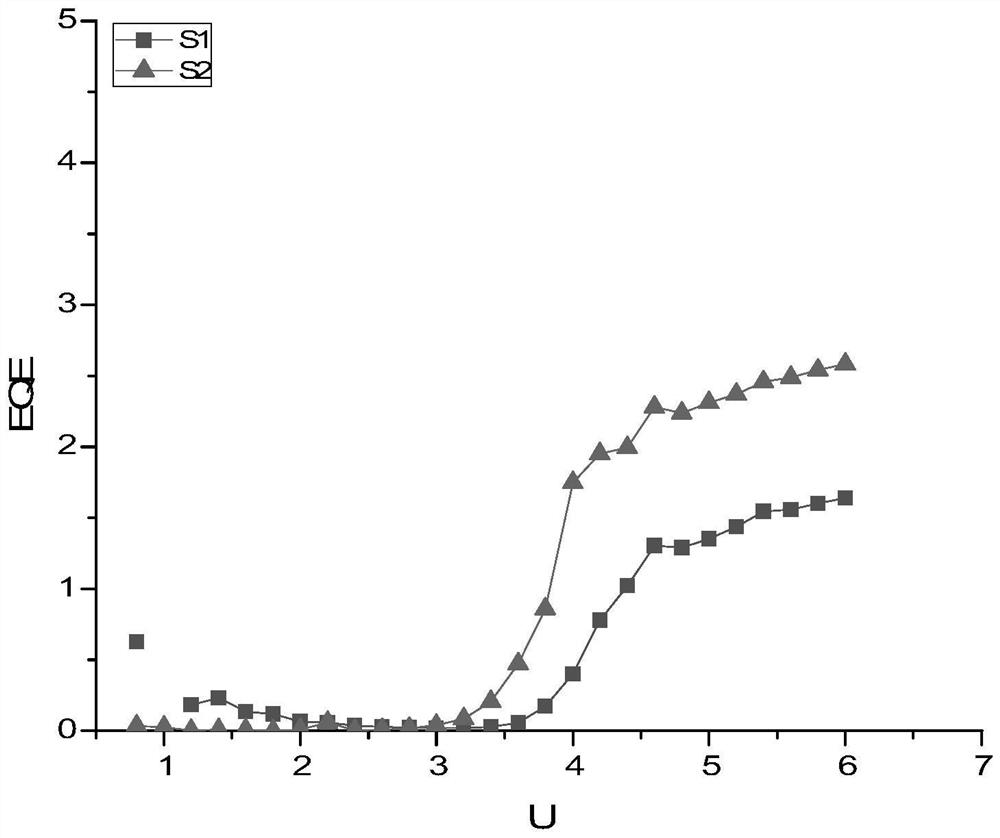

[0027] In the method for preparing a light-emitting device provided by the first aspect of the present application, after a metal oxide electron transport layer is prepared on the surface of the cathode, the electron transport layer is subjected to ...

Embodiment 1

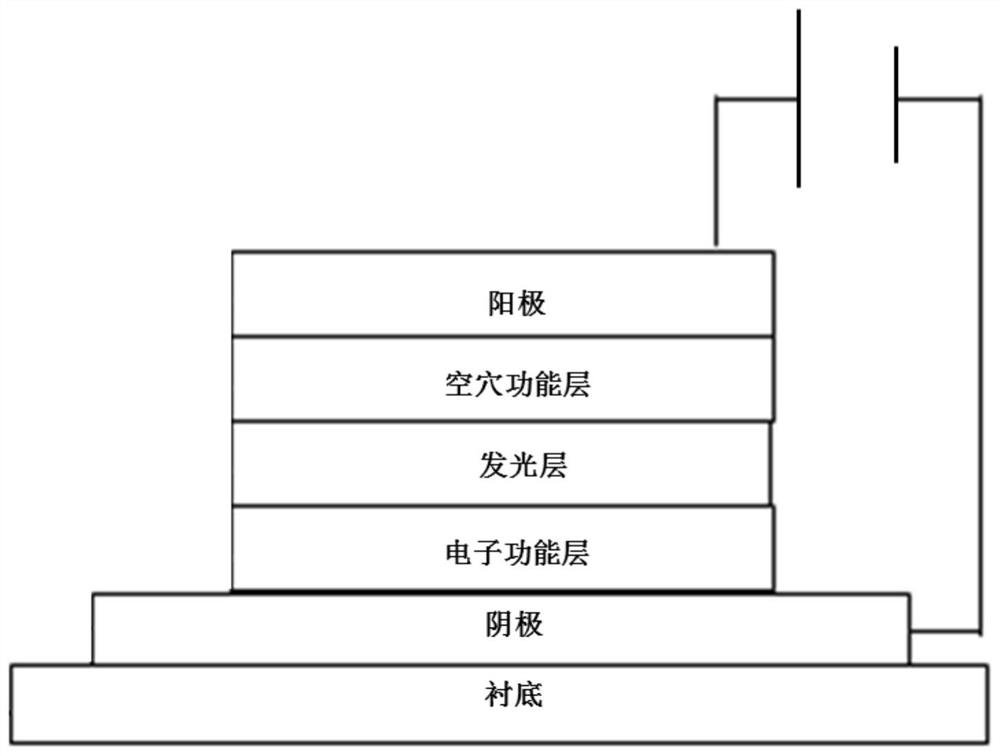

[0076] A light-emitting diode, comprising the following preparation steps:

[0077] (1) Provide a substrate on which Al cathode is deposited, and perform pre-cleaning treatment on the substrate.

[0078] (2) forming an electron transport layer on the Al cathode of step (1): in a glove box (water oxygen content is less than 0.1 ppm), spin-coat ZnO solution (concentration is 45 mg / mL, solvent is ethanol) on the ITO cathode , spin coating at 3000rpm for 30s and then anneal at 80℃ for 30min to form an electron transport layer.

[0079] (3) in H 2 The O content is less than 1 ppm and the temperature is 100°C, the electron transport layer is irradiated vertically from the electron transport layer side, UV wavelength 400nm, intensity 100mJ / cm 2 , UV time 30min.

[0080] (4) Form the light-emitting layer on the electron transport layer: take the CdSe / ZnS quantum dot solution (concentration is 30mg / mL, the solvent is n-octane), put the CdSe / ZnS quantum dot solution in a glove box (w...

Embodiment 2

[0086] A light-emitting diode, the difference between its preparation steps and Example 1 is: in step (3), vertical UV irradiation is performed from the cathode side, the UV wavelength is 300nm, and the intensity is 200mJ / cm 2 , UV time 30min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com