Cellulose nanowhisker, synthetic fiber, cement-based composite material and reinforcing method

A nano-whisker, synthetic fiber technology, applied in the field of fiber surface modification and modification, to achieve the effects of superior bonding performance, fiber surface improvement, and changing physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] This embodiment of the present invention provides a method for optimizing the design of functional groups on the surface of cellulose nanowhiskers. Based on the molecular dynamics simulation analysis of the adsorption performance of functional groups at the atomic level interface microstructure and chemical coordination, and the principle of quantum chemical calculation, the surface The functional groups were optimized to form functionalized cellulose nanowhiskers with the best adsorption performance with cement-based materials.

[0063] The atomic-level interface microstructure and chemical coordination are analyzed based on quantum chemical calculation and molecular dynamics simulation, and functional groups are optimized and designed with the help of deep learning according to adsorption characteristics:

[0064] (1) Multi-scale computational analysis of nanocellulose:

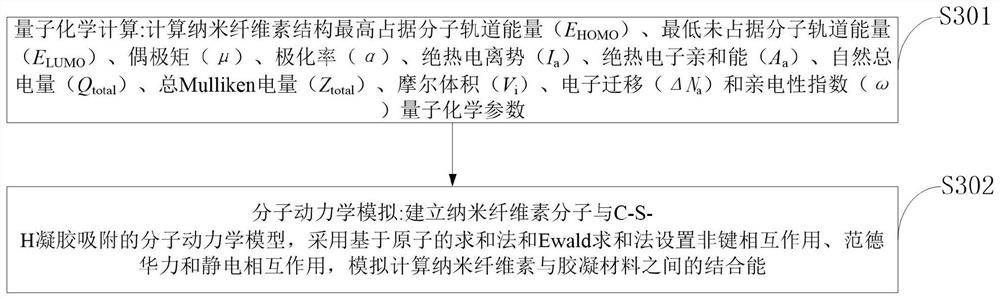

[0065] (1.1) Quantum chemical calculation: Calculate the highest occupied molecular orbital energ...

Embodiment 2

[0079] Based on the above Embodiment 1, this embodiment of the present invention provides a surface-modified synthetic fiber of cellulose nano-whiskers, and the surface-modified synthetic fiber of cellulose nano-whiskers is composed of the cellulose nano-whisker polymer nanomaterials. As a coating, it coats the surface of the PE fiber to form a rough surface structure, which makes the surface of the PE fiber rough.

Embodiment 3

[0081] Based on the above-mentioned Embodiment 2, this embodiment of the present invention provides a method for preparing a synthetic fiber surface-modified with cellulose nanowhiskers, including:

[0082] The cellulose nano-whiskers are configured into a mixed solution, and by soaking and heating to solidify, the cellulose nano-whiskers are coated on the surface of the PE fiber and form a film with sufficient electrostatic adsorption, and used as a coupling agent to strengthen the cellulose nano-crystals Bonding between synthetic fibers to be surface-modified and cement-based materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com