Super-hydrophobic composite anti-corrosion coating as well as construction method and application thereof

A super-hydrophobic and anti-corrosion technology, used in anti-corrosion coatings, coatings, metal material coating processes, etc., can solve the problems of poor binding force, low introduction of inorganic nanoparticles, poor anti-corrosion effect, etc., to enhance the binding force. , prolong the diffusion path and time, and improve the effect of anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Magnetically stir 0.28g of silane coupling agent KH-550 and 5g of absolute ethanol for 0.5h until the mixture is uniform. After that, 0.05 g ZnPA@ZIF-8 / PDA-MoS was added to the above mixed solution under ice bath condition 2 The nanocomposite materials were sonicated in an ultrasonic cell pulverizer for 5 min, then transferred to an ultrasonic cleaner for 20 min of sonication, magnetically stirred for 20 h after the end, washed and dried to obtain superhydrophobic ZnPA@ZIF-8 / PDA-MoS 2 Nanocomposites.

[0037] (2) Using the layer-by-layer spraying method, firstly, 1.0g of polyacrylate emulsion was evenly sprayed on the surface of the tinplate metal substrate after polishing with 800-mesh sandpaper, and dried and cured in a vacuum oven at 85°C for 5min; then 0.01g of triethylenetetramine was added. The cross-linking agent was mixed with 3 g of acetone uniformly, and then sprayed on the surface of the above coating; finally, 0.10 g of superhydrophobic ZnPA@ZIF-8 / PDA-M...

Embodiment 2

[0039] (1) Magnetically stir 0.30 g of silane coupling agent KH-570 and 7 g of absolute ethanol for 0.6 h until the mixture is uniform. After that, 0.07 g ZnPA@ZIF-8 / PDA-MoS was added to the above mixed solution under ice bath condition 2 The nanocomposites were sonicated in an ultrasonic cell pulverizer for 7 min, then transferred to an ultrasonic cleaner for 24 min, and then magnetically stirred for 22 h, washed and dried to obtain superhydrophobic ZnPA@ZIF-8 / PDA-MoS 2 Nanocomposites.

[0040] (2) Using the layer-by-layer spraying method, firstly, 1.1g of polyacrylate emulsion was evenly sprayed on the surface of the tinplate metal substrate polished with 800-mesh sandpaper, and dried and cured in a vacuum oven at 85°C for 7min; then 0.02g of aziridine was cross-linked Mixed with 4 g of anhydrous ethanol and sprayed on the surface of the above coating; finally, 0.12 g of superhydrophobic ZnPA@ZIF-8 / PDA-MoS 2 The nanocomposite was dispersed in 9g absolute ethanol for 36min ...

Embodiment 3

[0042] (1) Magnetically stir 0.33 g of hexamethyldisilazane and 9 g of anhydrous ethanol for 0.8 h until the mixture is uniform. After that, 0.09 g ZnPA@ZIF-8 / PDA-MoS was added to the above mixed solution under ice bath condition 2 The nanocomposite was sonicated in an ultrasonic cell pulverizer for 9 min, then transferred to an ultrasonic cleaner for 28 min, and then magnetically stirred for 24 h, washed and dried to obtain superhydrophobic ZnPA@ZIF-8 / PDA-MoS 2 Nanocomposites.

[0043] (2) Using the layer-by-layer spraying method, firstly, 1.2g of polyurethane emulsion was evenly sprayed on the surface of the tinplate metal substrate polished with 800-mesh sandpaper, and dried and cured in a vacuum oven at 85°C for 9min; then 0.03g of hexahydrophthalic anhydride was sprayed The cross-linking agent was mixed with 5 g of anhydrous ethanol uniformly, and then sprayed on the surface of the above coating; finally, 0.14 g of superhydrophobic ZnPA@ZIF-8 / PDA-MoS was added. 2 The na...

PUM

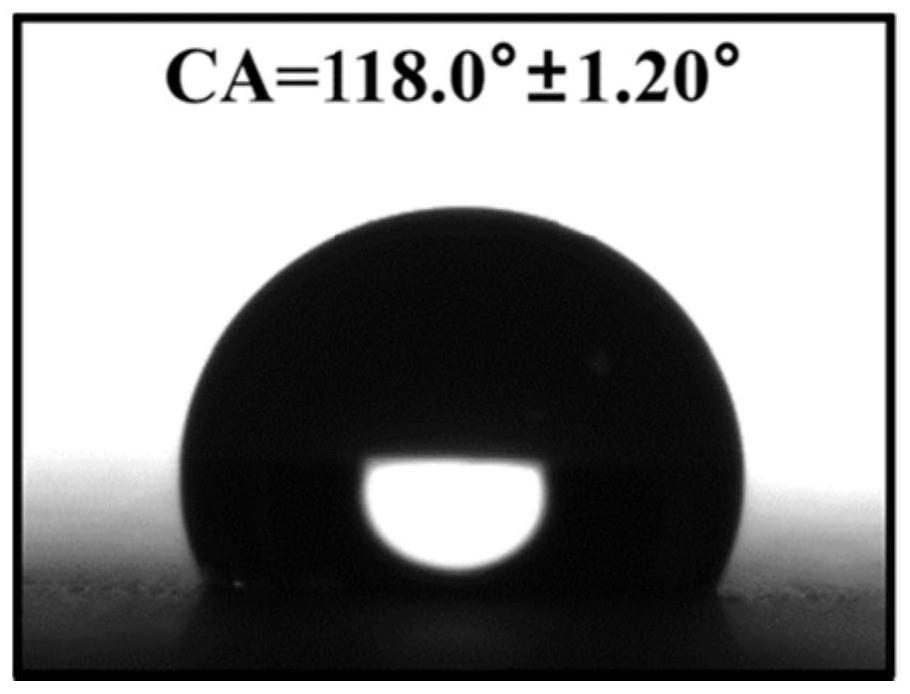

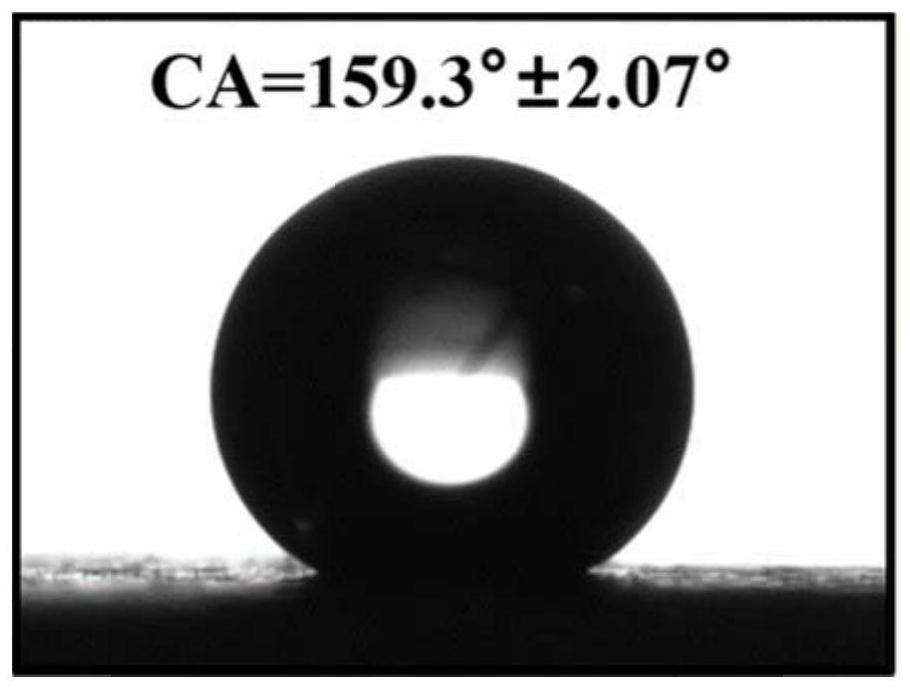

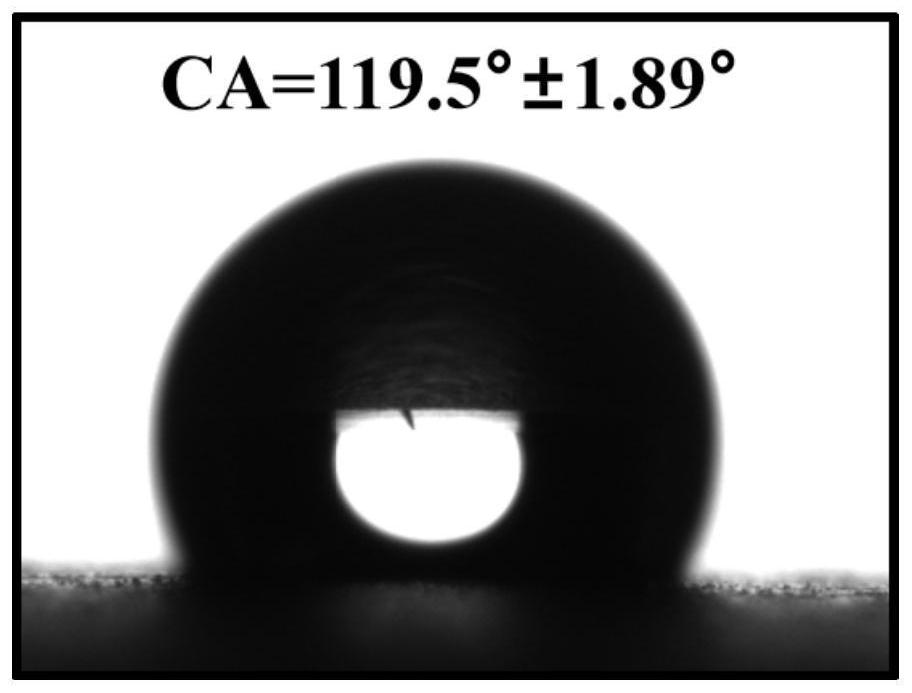

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com