Double-layer plastic, raw material composition as well as preparation method and application of double-layer plastic

A raw material composition, plastic technology, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of slow degradation, poor mechanical properties, low utilization of papermaking waste, etc. Crystal point, low price, the effect of protecting soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

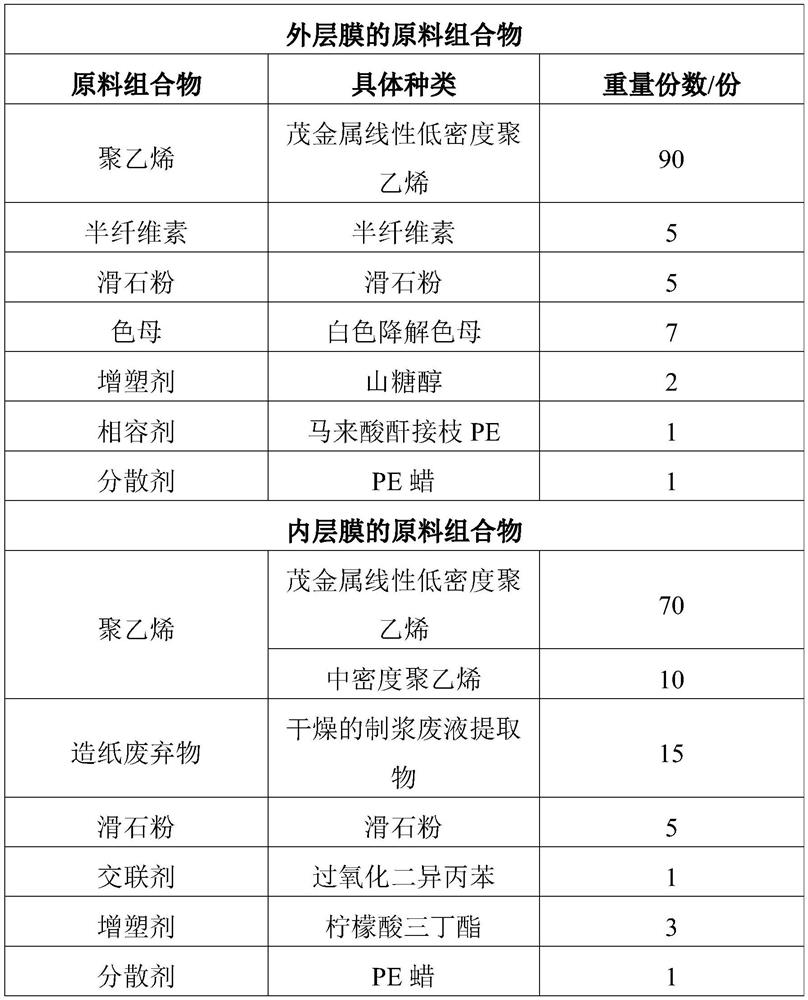

[0131] (1) The types and amounts of each component in the raw material composition of the outer layer film are shown in Table 1. The particle size of the hemicellulose is 1000 meshes. The raw material composition is added to a high-speed blender and mixed at a temperature of 150°C , the mixing speed is 300rpm, the mixing time is 90min, the above mixture is placed in a twin-screw extruder for extrusion and granulation, and the temperature of the twin-screw extruder from zone one to zone six is 150 ℃, 155 ℃, 170°C, 175°C, 180°C and 185°C; the temperature of the head of the twin-screw extruder is 175°C, and the rotational speed of the screw is 250rpm to obtain PE-hemicellulose masterbatch;

[0132] (2) The types and amounts of each component in the raw material composition of the inner layer film are shown in Table 1. The papermaking waste is the dried pulping waste liquid extract, and the particle size is 800 meshes. Each raw material composition is added into a high-speed ble...

Embodiment 2

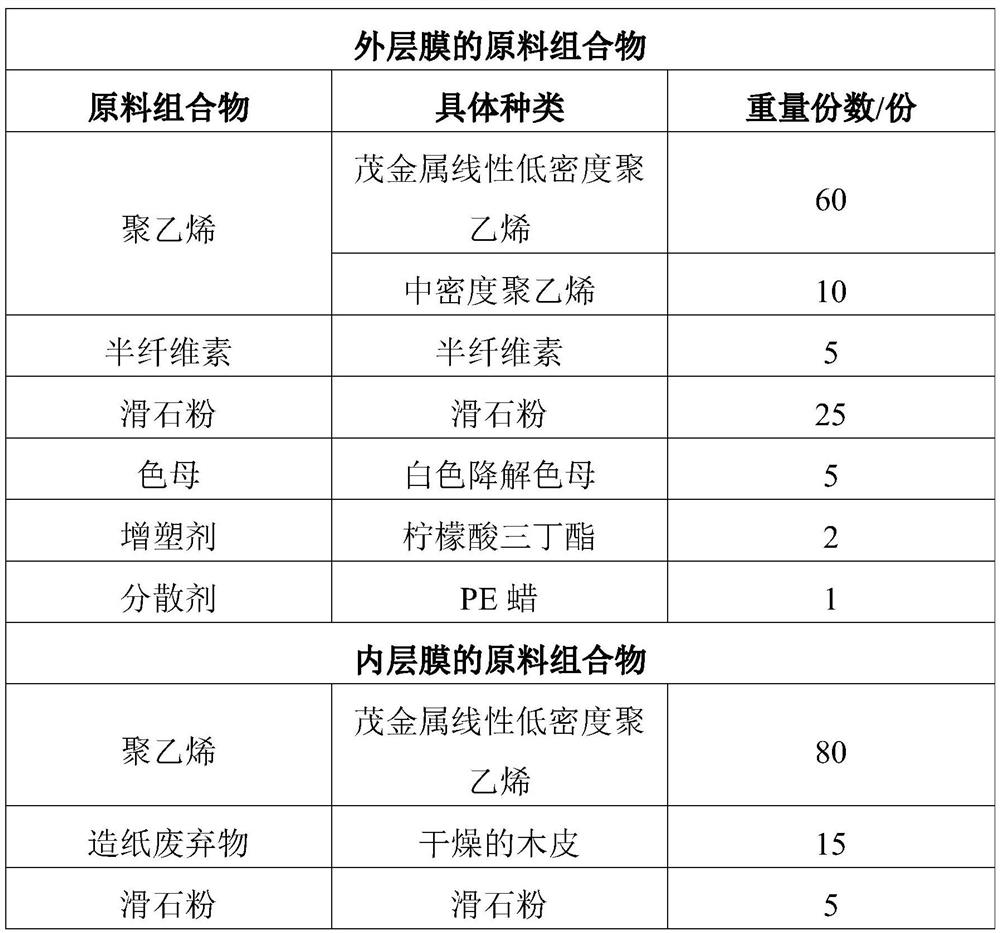

[0137] (1) See Table 2 for the types and amounts of each component in the raw material composition of the outer layer film. The particle size of the hemicellulose is 1200 mesh. The raw material composition is added to a high-speed blender and mixed at a temperature of 100°C , the mixing speed is 100rpm, the mixing time is 100min, the above mixture is placed in a twin-screw extruder for extrusion and granulation, and the temperature of the twin-screw extruder from zone one to zone six is 90 ℃, 135 ℃, 160°C, 165°C, 170°C and 170°C; the temperature of the head of the twin-screw extruder is 170°C, and the rotational speed of the screw is 220rpm to obtain PE-hemicellulose masterbatch;

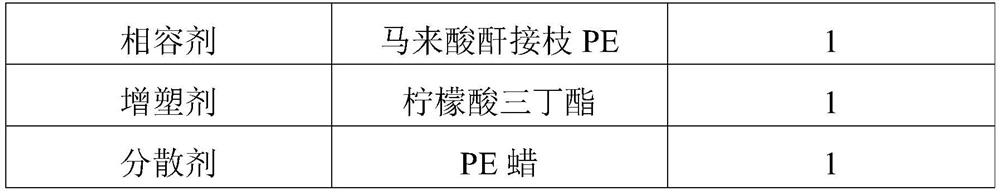

[0138] (2) See Table 2 for the types and amounts of each component in the raw material composition of the inner layer film. The papermaking waste is obtained by cleaning, drying, pulverizing and sieving the veneer, and the particle size of the dried veneer is 300 meshes. 300rpm, the mixing time i...

Embodiment 3

[0144] (1) See Table 3 for the types and amounts of each component in the raw material composition of the outer layer film. The particle size of the hemicellulose is 1200 meshes. The raw material composition is added to a high-speed blender and mixed at a temperature of 90°C , the mixing speed is 400rpm, the mixing time is 80min, the above mixture is placed in a twin-screw extruder for extrusion and granulation, and the temperature of the twin-screw extruder from zone one to zone six is 120 ℃, 145 ℃, 155°C, 170°C, 175°C and 175°C; the temperature of the head of the twin-screw extruder is 175°C, and the rotational speed of the screw is 190rpm to obtain PE-hemicellulose masterbatch;

[0145](2) The types and amounts of each component in the raw material composition of the inner layer film are shown in Table 3. The papermaking waste is obtained by cleaning, drying, pulverizing and sieving the pulp, and the particle size of the dried pulp is 1500 meshes. , adding each raw materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com