Crosslinkable cycloolefin copolymer as well as preparation method and application thereof

A technology of olefin copolymers and cross-linked rings, which is applied in the field of cross-linkable cyclic olefin copolymers and its preparation, can solve problems such as limited material use, unfavorable precision processing, complex systems, etc., and achieves easy shape change, convenient precision processing, Apply a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

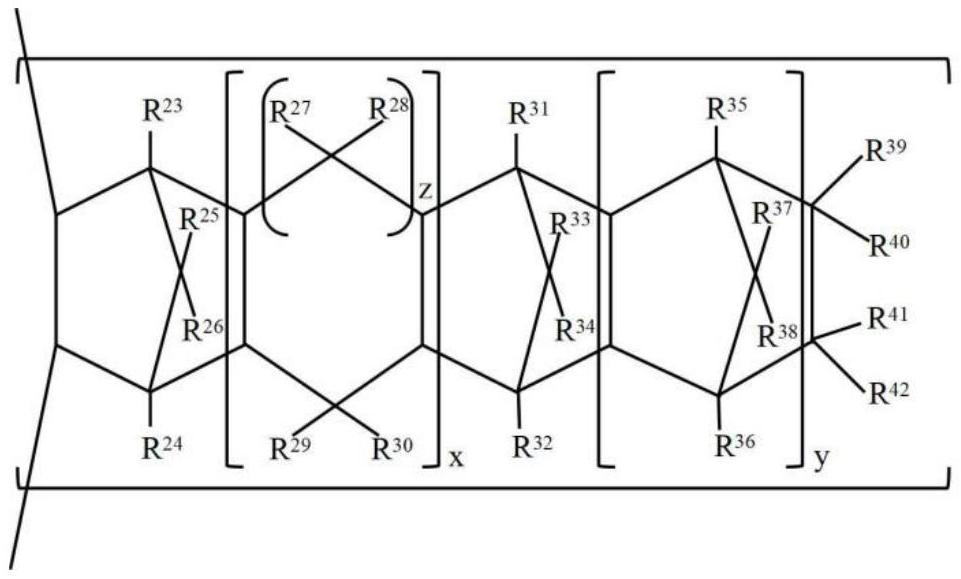

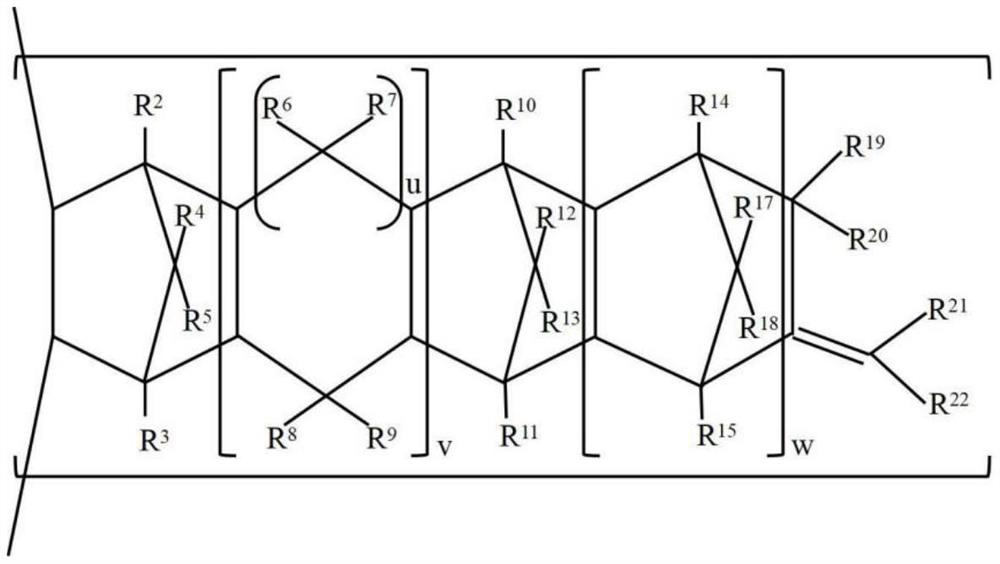

Method used

Image

Examples

Embodiment 1

[0065] The reaction kettle with an effective volume of 2L was treated with water and oxygen; the temperature of the reaction system was controlled to be 40°C; The system is uniform; ethylene monomer is introduced, about 2 g, and 1 ml of the main catalyst Cs-symmetric fluorenyl aminodimethyltitanium complex solution (the solute content is 20 μmol) and 40 μmol of the cocatalyst C2H5AlCl2 solution are successively injected with a syringe, and the reaction time is 20 minutes. After the polymerization, 50 g of absolute ethanol was injected into the reaction kettle to terminate the reaction, the solution was taken out, washed repeatedly with acetone and absolute ethanol, and then placed in an oven at 60 °C for 6 h after suction filtration. The cross-linkable cyclic olefin copolymer product is obtained, and after the cross-linkable cyclic olefin copolymer product is dried, it is stored and used for testing.

[0066] The types of main catalyst and co-catalyst used in Examples 2-18 are...

Embodiment 2-6

[0068] The content of each monomer in Examples 2-6 was adjusted according to Table 1, and the process parameters were adjusted according to Table 2, and others were the same as in Example 1.

[0069] Monomer formulations of Examples 2-6 of Table 1

[0070] Monomer a Monomer b monomer c Example 2 200 40 5 Example 3 200 100 35 Example 4 200 160 60 Example 5 200 240 70 Example 6 200 300 120

[0071] Solvent and process parameter of table 2 embodiment 2-6

[0072]

Embodiment 7-12

[0074] Source monomer a in embodiment 7-12 is The source monomer b is 5-ethyl-2-norbornene, the source monomer c is ethylene, and the reaction solvent is cyclohexane. .

[0075] Monomer formulations of Table 3 Examples 7-12

[0076] Monomer a Monomer b monomer c Example 7 200 20 2 Example 8 200 40 10 Example 9 200 100 30 Example 10 200 160 90 Example 11 200 240 110 Example 12 200 300 180

[0077] Solvent and process parameter of table 4 embodiment 7-12

[0078]

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com