Slow-release coagulation-accelerating composite material, preparation method thereof and application of slow-release coagulation-accelerating composite material in cement-based material

A technology for cement-based materials and composite materials, applied in the field of building material additives, can solve problems such as affecting the microstructure of cement stone and affecting the hardening performance of cement-based materials, and achieve the effect of shortening the setting time and promoting the formation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

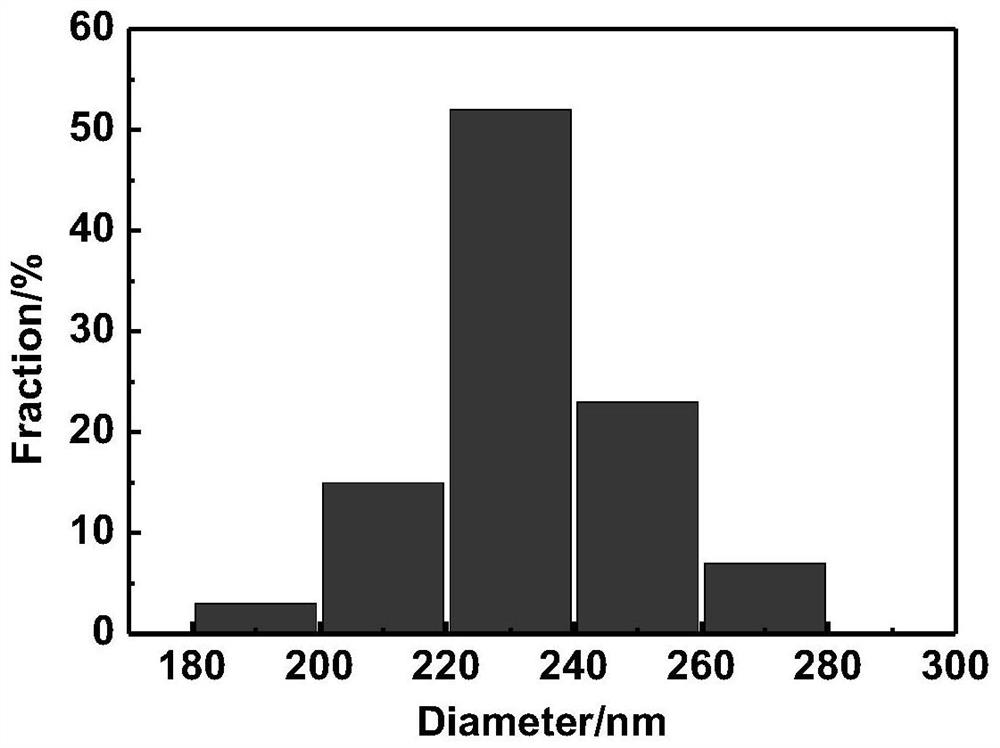

[0055] First, 5.0 g of aluminum sulfate was prepared into a 20 wt% aluminum sulfate solution as an aqueous solution of an inorganic salt coagulant.

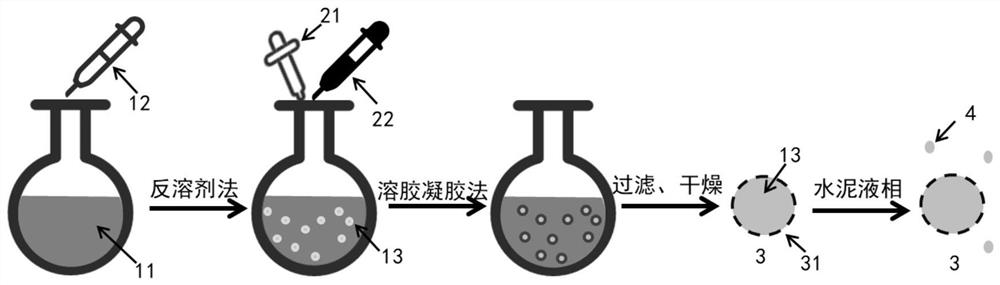

[0056] Then, a flask containing 200 g of ethanol was placed in an ultrasonic water tank, the ultrasonic dispersion was turned on, and the above-mentioned aluminum sulfate solution was added to the flask at a speed of 5 mL / h to 10 mL / h with a peristaltic pump, and aluminum sulfate particles were prepared by the anti-solvent method.

[0057] In the third step, 1.0g of ammonia water was added to the flask under ultrasonic stirring, and 20.0g of tetraethyl orthosilicate was added to the flask using a dropping funnel, and ultrasonically dispersed at 20°C to 30°C. In the reaction system, sulfuric acid was added. The aluminum particles are used as the growth point of micelles, and tetraethyl orthosilicate is hydrolyzed under the action of ammonia water, and undergoes a sol-gel reaction to generate porous nano-silica.

[0058] Finally, t...

Embodiment 2

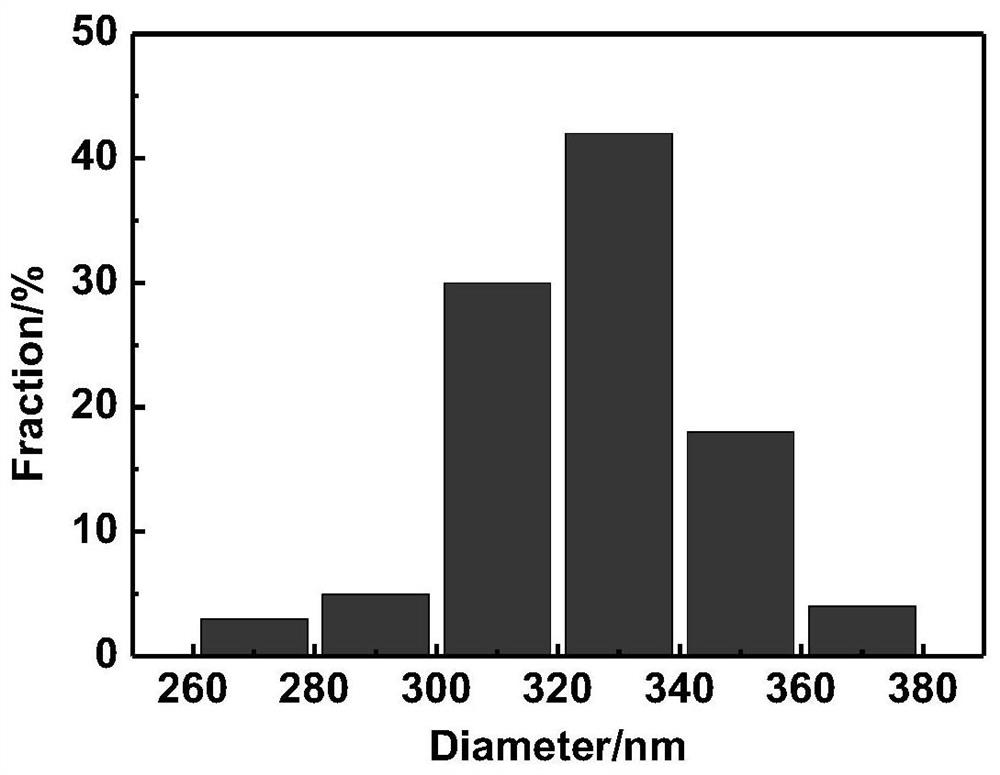

[0061] First, 3.0 g of sodium aluminate and 4.0 g of sodium silicate were respectively prepared into a sodium aluminate solution and a sodium silicate solution of 20 wt %.

[0062] Then, place a flask containing 200 g of acetone in an ultrasonic water tank, turn on ultrasonic dispersion, and add the above-mentioned sodium aluminate solution and sodium silicate solution to the flask at a speed of 5 mL / h to 10 mL / h with a peristaltic pump. Preparation of sodium aluminate particles and sodium silicate particles.

[0063] In the third step, 1.0g of ammonia water and 0.5g of triethanolamine were added to the flask under ultrasonic stirring, and 10.0g of methyl orthosilicate and 15.0g of butyl orthosilicate were added to the flask using a dropping funnel. Ultrasonic dispersion at ℃, sodium aluminate particles and sodium silicate particles are used as micelle growth points in the reaction system, methyl orthosilicate and butyl orthosilicate are hydrolyzed under the action of ammonia ...

Embodiment 3

[0067] First, 4.0 g of aluminum sulfate, 3.0 g of sodium silicate, 2.0 g of magnesium fluorosilicate and 1.0 g of sodium fluorosilicate were respectively prepared into 20 wt% aluminum sulfate solution, sodium silicate solution, magnesium fluorosilicate solution and Sodium Fluorosilicate Solution.

[0068] Then, place a flask containing a mixed organic reagent of 100g ethanol and 100g acetone in an ultrasonic water tank, turn on ultrasonic dispersion, and add the above four inorganic salts to the flask at a speed of 5mL / h~10mL / h with a peristaltic pump to accelerate coagulation. The aqueous solution of the agent is used to prepare aluminum sulfate particles, sodium silicate particles, magnesium fluorosilicate particles and sodium fluorosilicate particles by anti-solvent method.

[0069] In the third step, 1.5g of diethanolamine and 0.5g of tetraethylammonium hydroxide were added to the flask under ultrasonic stirring, and 15.0g of butyl orthosilicate and 15.0g of tetrabutyl tit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com