Method for pulverizing waste denitration catalyst and waste denitration catalyst powder prepared thereby

A waste denitrification catalyst and powder technology, which is applied in the direction of grain processing, etc., can solve the problems such as the difficulty of crushing the waste denitrification catalyst, and achieve a simple and easy crushing method, excellent strength and catalytic performance, and is conducive to subsequent processing and reuse. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] 1) Use a crusher to crush the waste denitration catalyst, and then screen out D 50 It is the pretreated powder below 30mm;

[0072] 2) Take 2.5g of the pretreated powder obtained in step 1) and put it into a teflon ball mill jar, add 25g of zirconia ball mill beads, including 15g of large ball mill beads with a diameter of 3-5.2mm and a diameter of 0.87mm 10g of small ball grinding beads, then add 3mL polyoxyethylene lauryl ether aqueous solution, the pH of the solution is 6.7, and the polyoxyethylene lauryl ether content is 10g / L;

[0073] 3) Ball milling for 2h under the condition of rotating speed of 200r / min;

[0074] 4) filtering the ball-milling slurry obtained in step 3), removing the ball-milling beads, and washing the ball-milling slurry obtained after filtering with an ethanol solution with a concentration of 99.5% by weight, wherein the content of the ethanol solution is 5 times the volume of the ball-milling slurry, After washing, it was placed at 25 °C fo...

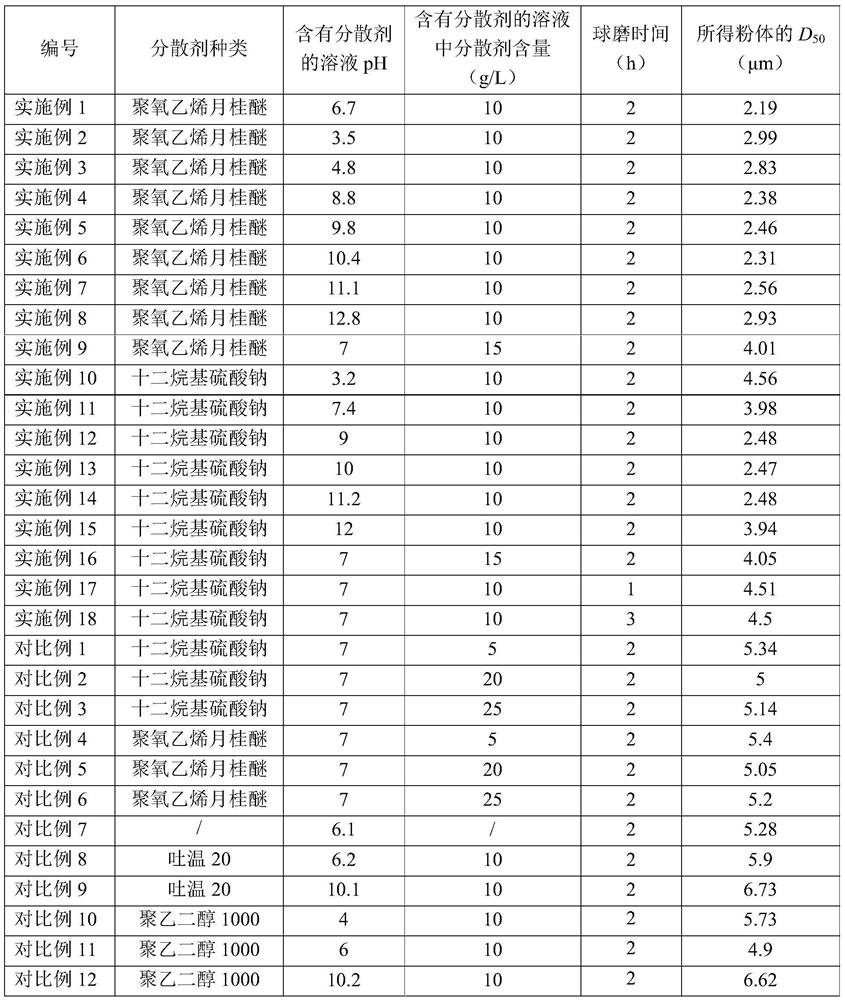

Embodiment 2-18 and comparative example 1-12

[0076] Carry out according to the method of embodiment 1, the difference is:

[0077] The pH of polyvinyl lauryl ether solution and the consumption of polyoxyethylene lauryl ether are different in embodiment 2-9;

[0078] In embodiment 10-18, dispersant is sodium lauryl sulfate, and the pH of sodium lauryl sulfate solution, the consumption of sodium lauryl sulfate and ball milling time are different;

[0079] In Comparative Examples 1-3, the dispersant is sodium lauryl sulfate, and its consumption is different;

[0080] In Comparative Examples 4-6, the dispersing agent is polyoxyethylene lauryl ether, and its consumption is different;

[0081] In Comparative Example 7, without using a dispersant, the polyoxyethylene lauryl ether aqueous solution in Example 1 was replaced with 3 mL of deionized water;

[0082] Comparative examples 8-12 replace polyoxyethylene lauryl ether with different dispersants (Tween 20 or polyethylene glycol 1000), and the pH of the solutions containing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com