CuCd-MOF/GO-x composite material with visible light catalytic degradation performance and preparation and application thereof

A composite material and catalytic degradation technology, applied in the field of CuCd-MOF/GO-x composite material and its preparation, can solve the problems of unclear broad-spectrum degradation effect and low degradation efficiency of catalysts, and achieve superior photocatalytic degradation rate and high preparation efficiency. High efficiency and convenient operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

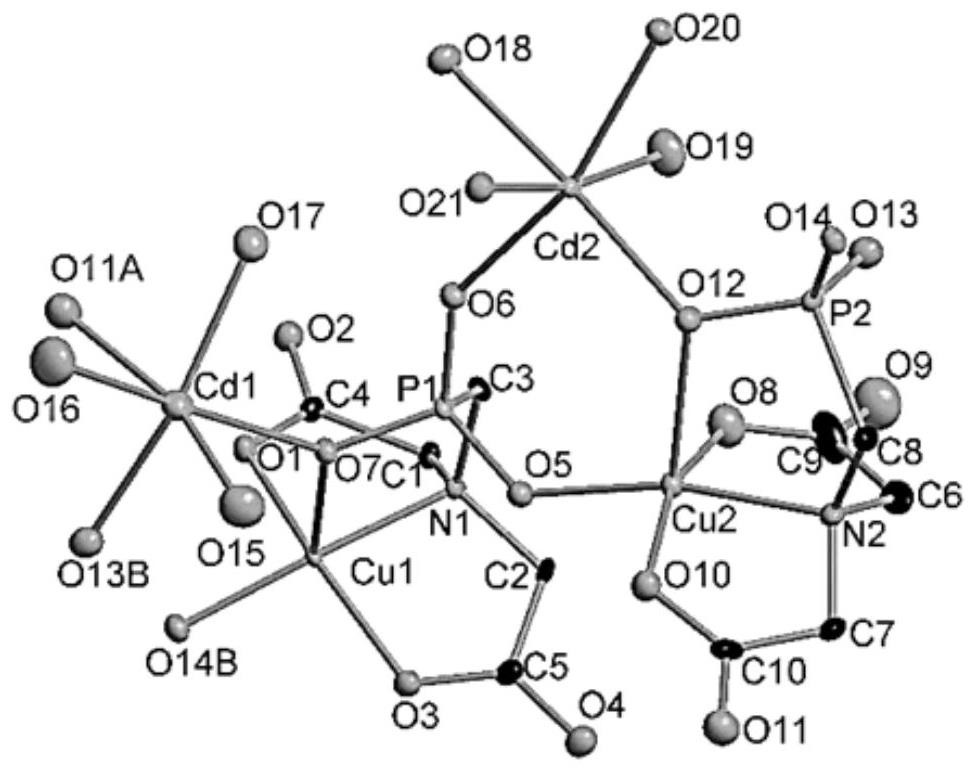

[0035] Example 1: Preparation of CuCd-MOF material

[0036] Weigh 0.0998g of copper acetate, 0.1333g of cadmium acetate and 0.1136g of N-(phosphonomethyl)iminodiacetic acid and dissolve in 6mL of water, ultrasonically make them evenly mixed, and then transfer to a 50mL autoclave. The reaction was carried out in an oven for 48 hours, cooled to room temperature, washed with ultrapure water and absolute ethanol, and dried to obtain blue crystals. The blue crystal is a pure CuCd-MOF material without doping GO, that is, the value of x in CuCd / GO-x is 0, that is, a pure CuCd-MOF material.

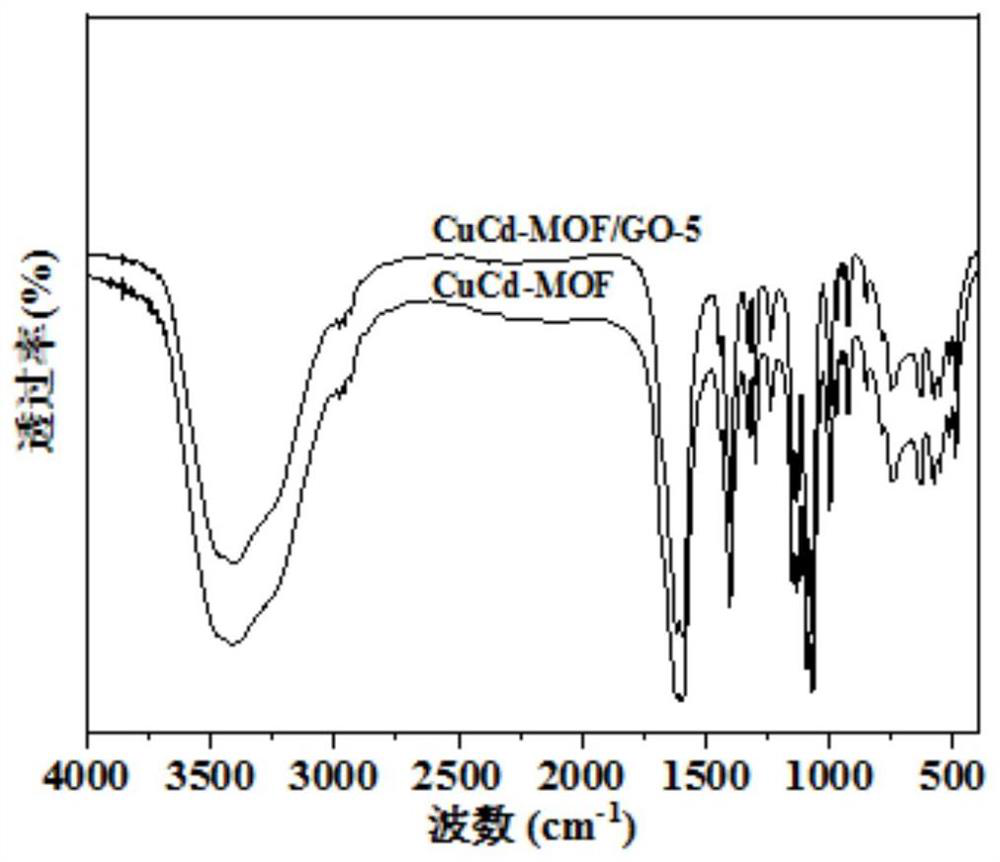

[0037] The obtained CuCd-MOF was characterized by infrared spectroscopy, and the specific results were IR(KBr,cm-1): 3408(s), 1620(s), 1593(s), 1442(w), 1402(m), 1326(w) ), 1299(w), 1240(w), 1149(m), 1130(m), 1091(s), 1070(s), 997(m), 923(w), 850(w), 788(m ), 750(m), 632(m), 578(m), 555(m), 514(w)( image 3 ).

Embodiment 2

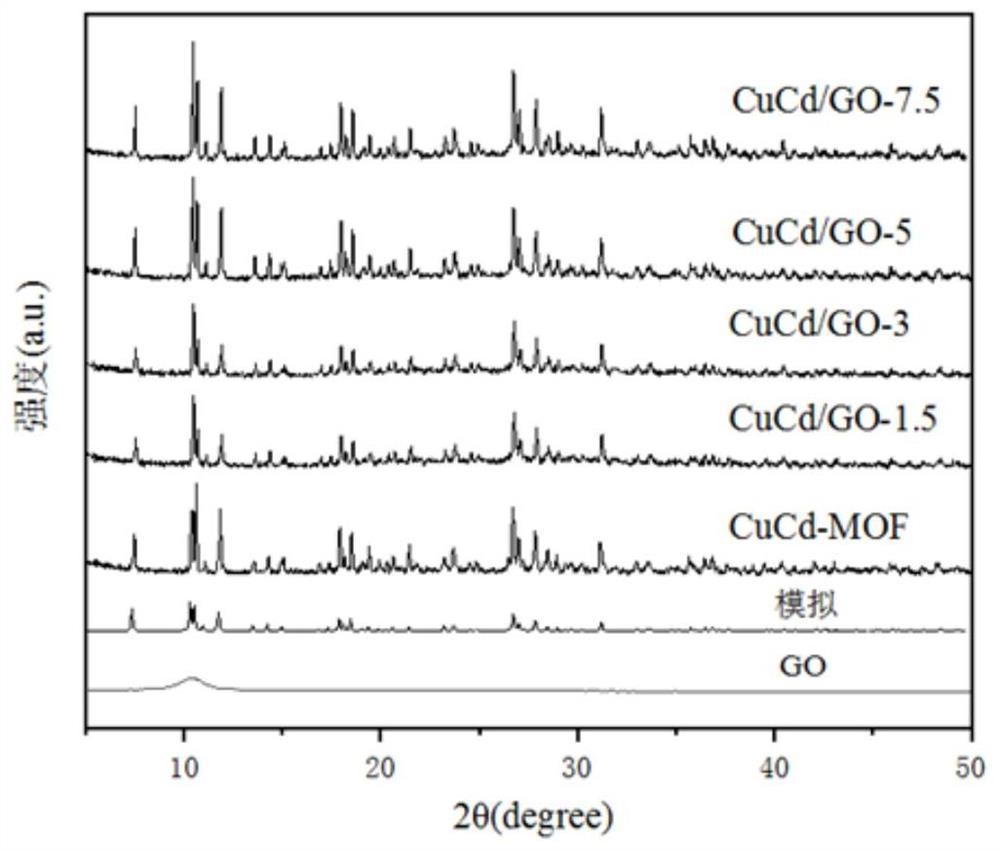

[0038] Example 2: Preparation of CuCd-MOF / GO-1.5 composite visible light catalyst

[0039] Weigh 0.0998g of copper acetate, 0.1333g of cadmium acetate and 0.1136g of N-(phosphonomethyl)iminodiacetic acid and dissolve it in 6mL of water, add 0.0052g of graphene oxide to the solution system, ultrasonically make it evenly mixed and then transfer to In a 50mL autoclave, react in an oven at 100°C for 48h, cool to room temperature, wash with ultrapure water and absolute ethanol, and dry to obtain blue-black crystals. The blue-black crystal is a CuCd-MOF / GO composite material with a GO doping ratio of 1.5%, denoted as CuCd-MOF / GO-1.5.

Embodiment 3

[0040] Example 3: CuCd-MOF / GO-3 composite visible light catalyst and its preparation

[0041] Weigh 0.0998g of copper acetate, 0.1333g of cadmium acetate and 0.1136g of N-(phosphonomethyl)iminodiacetic acid and dissolve it in 6mL of water, add 0.0104g of graphene oxide to the solution system, ultrasonically make it evenly mixed and then transfer to In a 50mL autoclave, react in an oven at 100°C for 48h, cool to room temperature, wash with ultrapure water and absolute ethanol, and dry to obtain blue-black crystals. The blue-black crystal is a CuCd-MOF / GO composite material with a GO doping ratio of 3%, denoted as CuCd-MOF / GO-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com