Exposed (001) crystal face titanium dioxide/titanium carbide nanosheet as well as preparation method and application thereof

A technology of titanium dioxide and titanium carbide, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of application limitations, weak photocatalytic performance, etc., achieve excellent conductivity and improve separation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

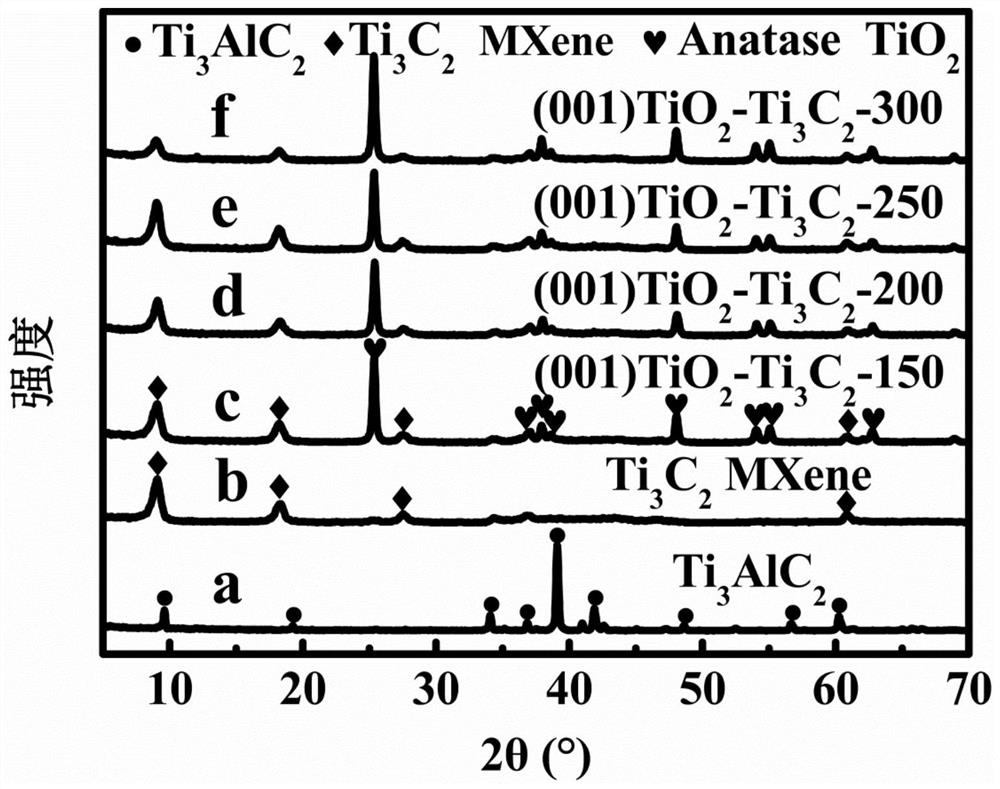

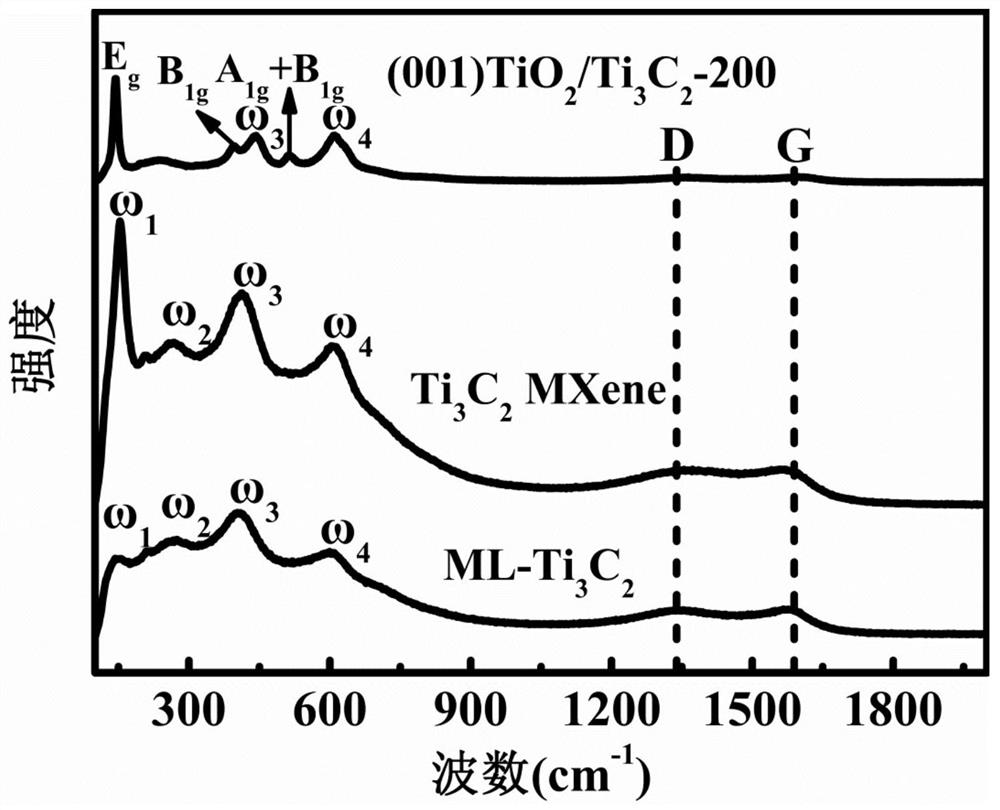

[0047] Step 1: Add MAX phase ceramic powder Ti 3 AlC 2 Add it into the HF solution at a concentration of 0.1g / mL, stir at room temperature for 27 hours to obtain a reaction solution, wash the reaction solution with deionized water and ethanol to a pH of 6, and then vacuum dry it at 60°C for 12 hours to obtain ML-Ti 3 C 2 Powder;

[0048] Step 2: Take 1g ML-Ti 3 C 2 Disperse in 40mL deionized water, ultrasonically break at room temperature for 100min, and the ultrasonic power is 70W, to obtain Ti 3 C 2 MXene solution, the Ti 3 C 2 The MXene solution was collected by centrifugation and dried under vacuum at 60 °C for 12 h to obtain Ti 3 C 2 MXene.

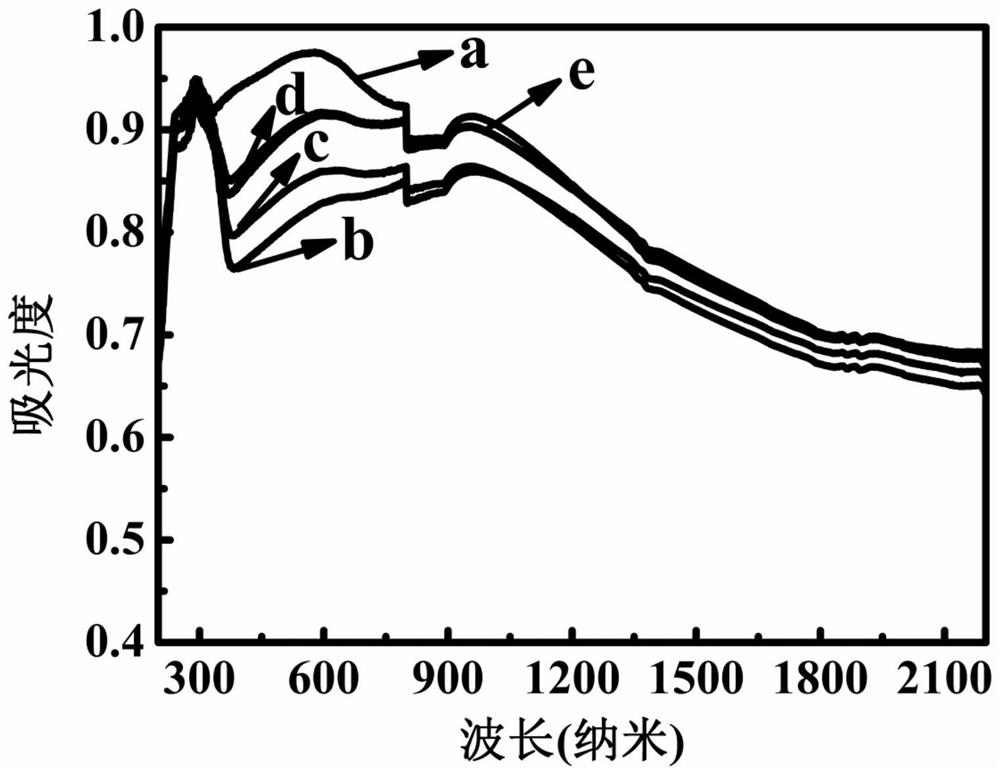

[0049] Step 3, take 150mgTi 3 C 2 Add MXene to 30mL HCl solution with a concentration of 1mol / L, and add 0.33gNaBF at the same time 4 As a crystal surface control agent, stir for 30 minutes, ultrasonic for 10 minutes, then transfer to a polytetrachlorethylene hydrothermal reaction kettle for hydrothermal reaction at ...

Embodiment 2

[0051] Step 1: Add MAX phase ceramic powder Ti 3 AlC 2 Add HF solution at a concentration of 0.1 g / mL, stir at room temperature for 27 hours to obtain a reaction solution, centrifuge the reaction solution with deionized water and ethanol to pH 7, and then vacuum-dry it at 60°C for 12 hours to obtain ML-Ti 3 C 2 ;

[0052] Step 2: Take 1g ML-Ti 3 C 2 Disperse in 40mL deionized water, ultrasonically break at room temperature for 100min, and the ultrasonic power is 70W, to obtain Ti 3 C 2 MXene solution, the Ti 3 C 2 The MXene solution was collected by centrifugation and dried under vacuum at 60 °C for 12 h to obtain Ti 3 C 2 MXene.

[0053] Step 3, take 200mgTi 3 C 2 Add MXene to 30mL HCl solution with a concentration of 1mol / L, and add 0.33gNaBF at the same time 4 As a crystal surface control agent, stir for 30 minutes, ultrasonic for 10 minutes, then transfer to a polytetrachlorethylene hydrothermal reaction kettle for hydrothermal reaction at 160°C for 12 hou...

Embodiment 3

[0055] Step 1: Add MAX phase ceramic powder Ti 3 AlC 2 Add it into the HF solution at a concentration of 0.1g / mL, stir at room temperature for 27 hours to obtain a reaction solution, wash the reaction solution with deionized water and ethanol to a pH of 6, and then vacuum dry it at 60°C for 12 hours to obtain ML-Ti 3 C 2 ;

[0056] Step 2: Take 1g ML-Ti 3 C 2 Disperse in 40mL deionized water, ultrasonically break at room temperature for 100min, and the ultrasonic power is 70W, to obtain Ti 3 C 2 MXene solution, the Ti 3 C 2 The MXene solution was collected by centrifugation and dried under vacuum at 60 °C for 12 h to obtain Ti 3 C 2 MXene.

[0057] Step 3, take 250mgTi 3 C 2 Add MXene to 30mL HCl solution with a concentration of 1mol / L, and add 0.33gNaBF at the same time 4 As a crystal surface control agent, stir for 30 minutes, ultrasonic for 10 minutes, then transfer to a polytetrachlorethylene hydrothermal reaction kettle for hydrothermal reaction at 160°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com