Composite photocatalyst as well as preparation method and application thereof

A technology of catalyst and composite light, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of poor hydrogen production activity, achieve low cost, improve electron-hole separation efficiency, and operate Simple and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

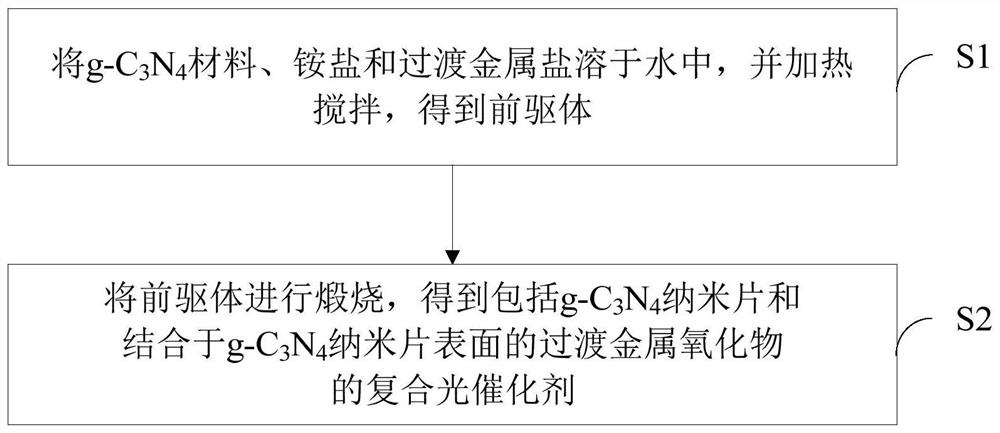

Method used

Image

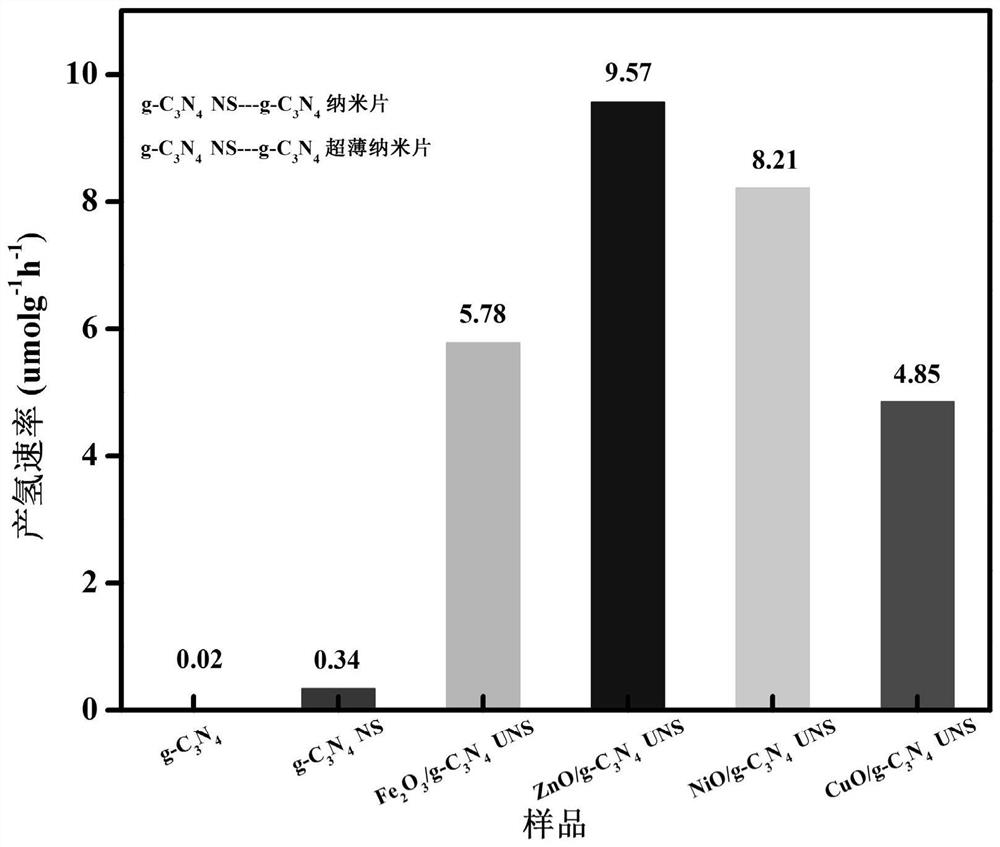

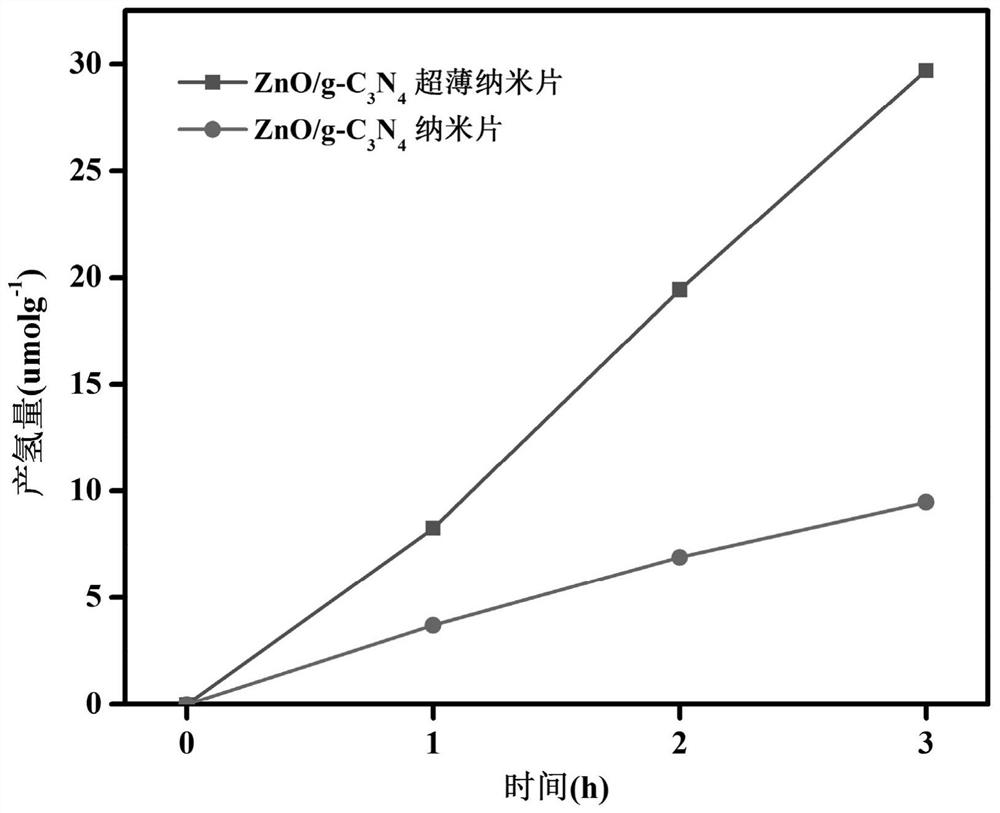

Examples

Embodiment 1

[0057] Fe in this example 2 O 3 / g-C 3 N 4 The preparation steps of the composite photocatalyst are as follows:

[0058] g-C 3 N 4 Preparation of materials: put 10 g of urea in a crucible, and place it in a muffle furnace for calcination at 550°C for 2 hours, with a heating rate of 5°C / min. The calcined product is washed with distilled water, filtered, dried in an oven and ground to obtain g-C 3 N 4 Material.

[0059] Vapor intercalation exfoliation g-C 3 N 4 Materials and Fe 2 O 3 Precursor preparation: 200 mg g-C 3 N 4 The material, 1 g of ammonium chloride and 100 mg of ferric chloride were dissolved in 30 mL of deionized water and sonicated for 10 minutes until uniformly dispersed. It was then placed in a fume hood and heated at 90°C with constant stirring with a glass rod until the precursor was obtained.

[0060] Fe 2 O 3 / g-C 3 N 4 Preparation of composite photocatalyst: The precursor was placed in a porcelain boat, calcined in a muffle furnace at 600...

Embodiment 2

[0062] This example ZnO / g-C 3 N 4 The preparation steps of the composite photocatalyst are as follows:

[0063] g-C 3 N 4 Preparation of materials: put 10 g of urea in a crucible, and place it in a muffle furnace for calcination at 550°C for 2 hours, with a heating rate of 5°C / min. The calcined product is washed with distilled water, filtered, dried in an oven and ground to obtain g-C 3 N 4 Material.

[0064] Vapor intercalation exfoliation g-C 3 N 4 Materials and ZnO precursor preparation: 200 mg g-C 3 N 4 The material, 1.4 g of ammonium nitrate and 75 mg of zinc nitrate were dissolved in 30 mL of deionized water and sonicated for 10 minutes until uniformly dispersed. It was then placed in a fume hood and heated at 75°C with constant stirring with a glass rod until the precursor was obtained.

[0065] ZnO / g-C 3 N 4 Preparation of composite photocatalyst: The precursor was placed in a porcelain boat, calcined at 500 °C for 2 h in a muffle furnace, and the heating ...

Embodiment 3

[0067] This example NiO / g-C 3 N 4 The preparation steps of the composite photocatalyst are as follows:

[0068] g-C 3 N 4 Preparation of materials: put 10 g of urea in a crucible, and place it in a muffle furnace for calcination at 550°C for 2 hours, with a heating rate of 5°C / min. The calcined product is washed with distilled water, filtered, dried in an oven and ground to obtain g-C 3 N 4 Material.

[0069] Vapor intercalation exfoliation g-C 3 N 4 Materials and NiO precursor preparation: 200 mg g-C 3 N 4 The material, 1.3 g of ammonium acetate and 80 mg of nickel acetate were dissolved in 30 mL of deionized water and sonicated for 10 minutes until uniformly dispersed. It was then heated at 80°C in a fume hood with constant stirring with a glass rod until the precursor was obtained.

[0070] NiO / g-C 3 N 4 Preparation of composite photocatalyst: The precursor was placed in a porcelain boat, calcined in a muffle furnace at 600 °C for 2 h, and the heating rate was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com