Transition metal-based hybrid material nanotube as well as preparation method and application thereof

A transition metal and transition metal salt technology, applied in chemical instruments and methods, catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, etc. The problem of harsh reaction conditions, etc., achieves the effect of simple and efficient synthesis method, improved energy utilization rate, and high controllability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A transition metal-based hybrid material nanotube and a preparation method thereof, comprising the following steps:

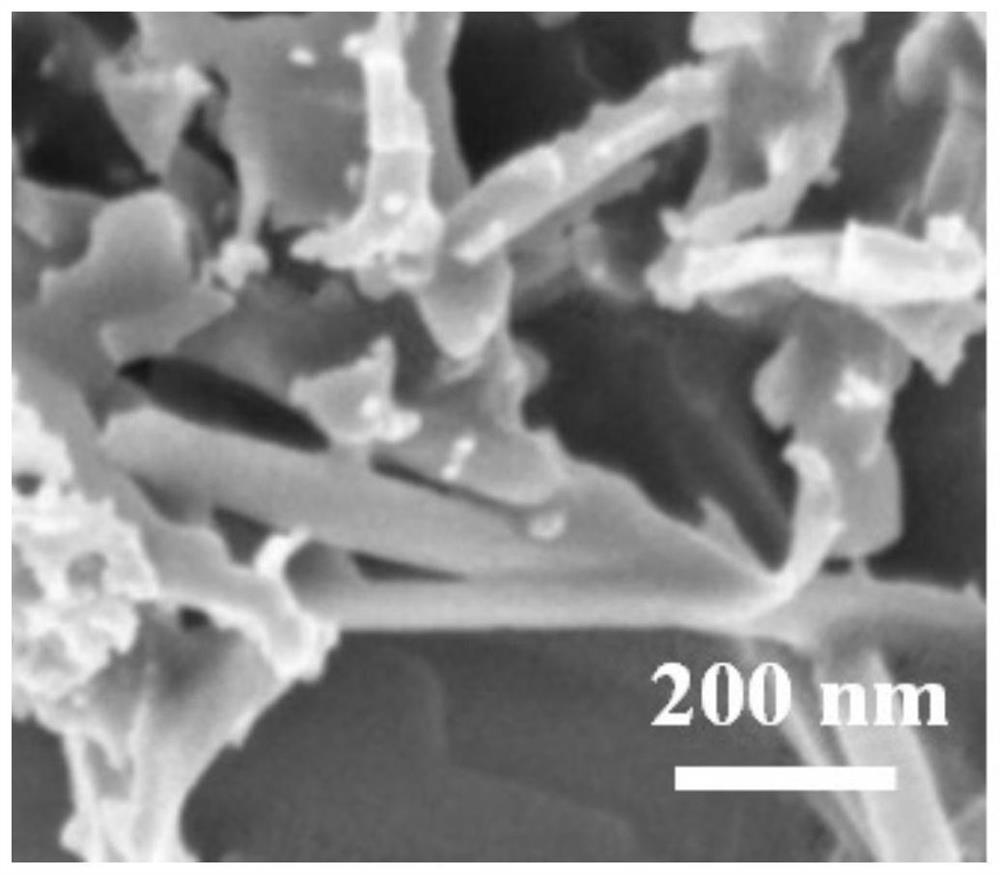

[0033] S1, weigh 404mg iron nitrate Fe (NO 3 ) 3 9H 2 O was dissolved in 8 mL of deionized water and stirred for 1 min to form a homogeneous solution; 300 mg of melamine was uniformly dispersed in the above solution; 900 mg of anhydrous citric acid was added and stirred for 5 min to form a homogeneous mixed solution. The pH of the test solution was 5-6, and then continuously Stir for 2 hours to obtain a yellow turbid solution, then centrifuge the yellow turbid solution at a speed of 3000 rpm for 5 minutes to obtain a precipitate;

[0034] S2. The precipitate of S1 is washed with deionized water until the system becomes neutral, and freeze-dried overnight to obtain transition metal iron-based hybrid material nanotubes in the form of yellow powder.

Embodiment 2

[0036] A transition metal-based hybrid material nanotube and a preparation method thereof, comprising the following steps:

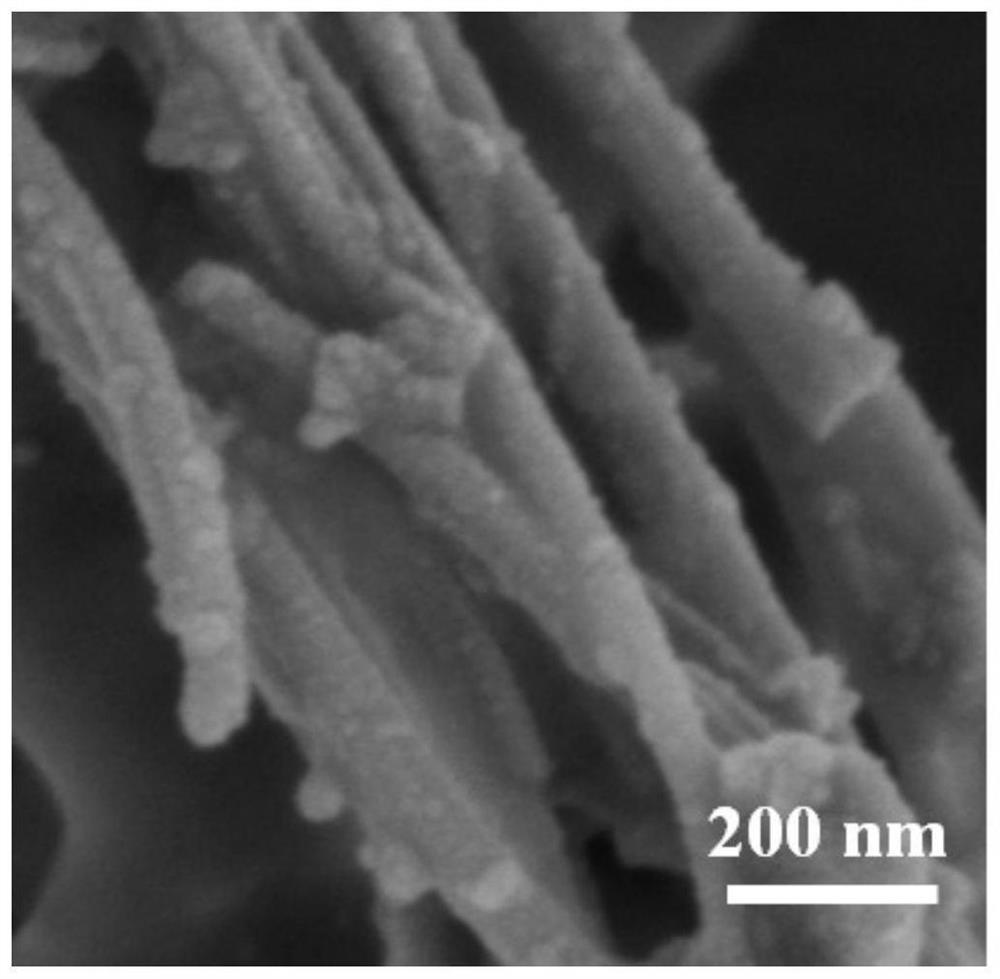

[0037] S1, weigh 240mg copper nitrate Cu(NO 3 ) 2 ·3H 2 O was dissolved in 8 mL of deionized water and stirred for 1 min to form a homogeneous solution; 300 mg of melamine was uniformly dispersed in the above solution; 900 mg of anhydrous citric acid was added and stirred for 5 min to form a homogeneous mixed solution. The pH of the test solution was 5-6, and then continuously Stir for 2 hours to obtain a blue turbid solution, then centrifuge the blue turbid solution at a speed of 5000 rpm for 3 minutes to obtain a precipitate;

[0038] S2. The precipitate of S1 is washed with deionized water until the system becomes neutral, and freeze-dried overnight to obtain transition metal copper-based hybrid material nanotubes in the form of blue powder.

Embodiment 3

[0040] A transition metal-based hybrid material nanotube and a preparation method thereof, comprising the following steps:

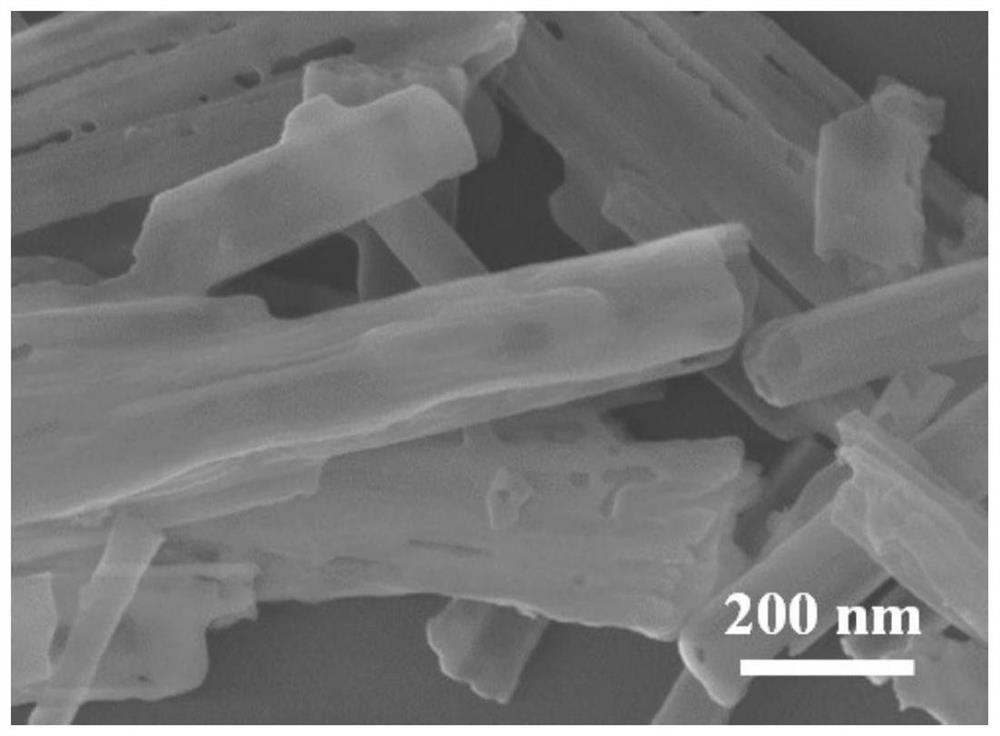

[0041] S1, weigh 404mg iron nitrate Fe (NO 3 ) 3 9H 2 O and 290mg nickel nitrate Ni(NO 3 ) 2 ·6H 2 O was dissolved in 8 mL of deionized water and stirred for 1 min to form a homogeneous solution; 300 mg of melamine was uniformly dispersed in the above solution; 900 mg of anhydrous citric acid was added and stirred for 5 min to form a homogeneous mixed solution. The pH of the test solution was 5-6, and then continuously Stir for 2 hours to obtain a yellow turbid solution, then centrifuge the yellow turbid solution at a speed of 4000 rpm for 4 minutes to obtain a precipitate;

[0042] S2. The precipitate of S1 was washed with deionized water until the system became neutral, and freeze-dried overnight to obtain transition metal iron-nickel-based hybrid material nanotubes in the form of yellow powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com