Hydrophobic modification method for powder composition and cosmetic containing same

A technology of hydrophobic modification and composition, which is applied in the direction of cosmetics, cosmetics, cosmetic preparations, etc., and can solve the problems of high cost and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

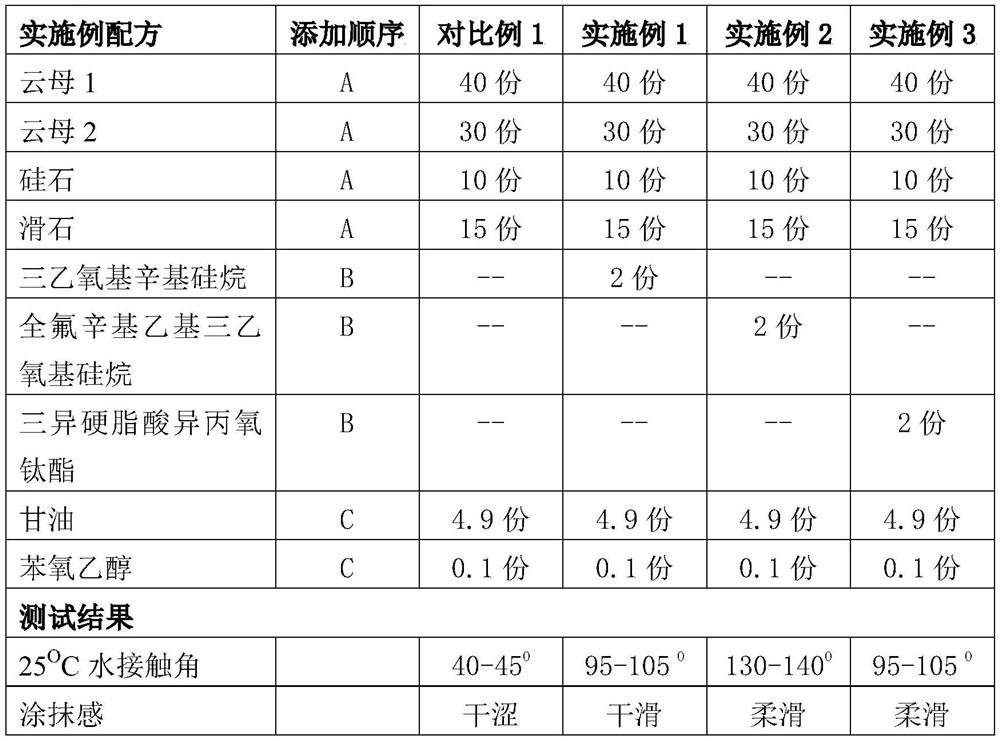

[0073] Embodiment 1-3: the formula and process of loose powder containing the powder composition processed by this method

[0074] Prepare loose powder according to the formula and addition order in Table 1. The specific preparation process is as follows: add phase A to the mixing device after weighing according to the formula, and slowly add phase B into phase A under low-speed stirring, and the dropwise addition is completed. Then continue to stir for 15 minutes until phase B is evenly mixed in phase A. The mixed powder is heated and dried at a temperature of 60 to 150 degrees Celsius, and the drying time is 0.5 to 8 hours. After drying, it is cooled to room temperature, and phase C is added to mix evenly, sieved and packaged.

[0075] Table 1

[0076]

[0077]

[0078] The test results are shown in Table 1 above. Compared with the loose powder in Comparative Example 1, the loose powders hydrophobically modified by the method of the present invention in Examples 1-3 a...

Embodiment 4-5

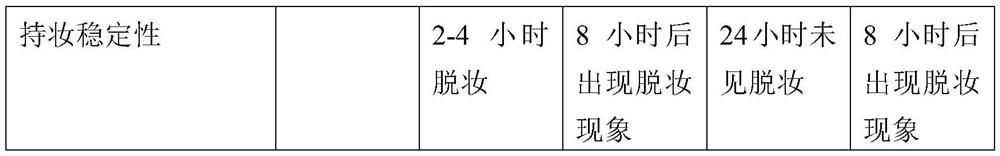

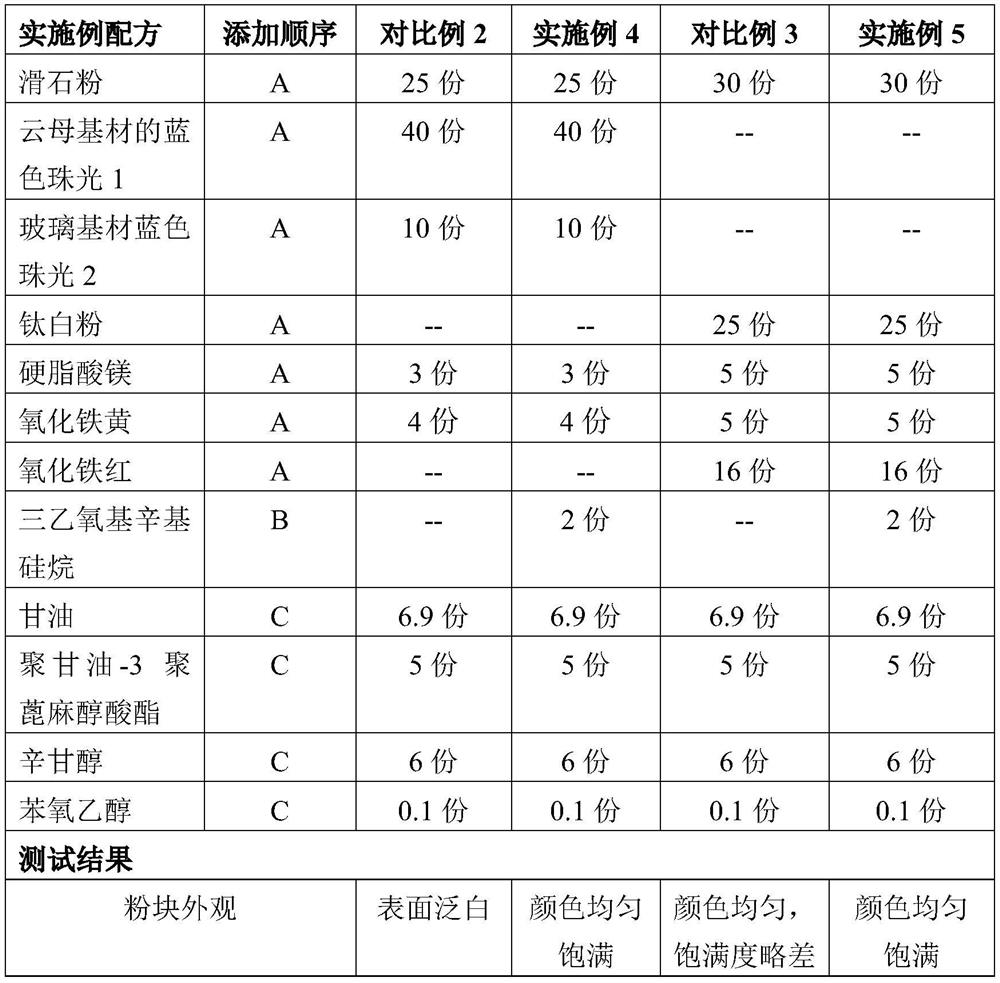

[0079] Example 4-5: Eye shadow and process containing powder composition treated by this method

[0080] Specifically, Example 4 is a highlight eye shadow, and Example 5 is a matte eye shadow. Prepare according to the formula and order of addition in Table 2. The specific preparation process is as follows: add phase A and phase B into the reactor in proportion, and stir at high speed for 15 minutes; under continuous stirring, the reactor is heated to 60-150 degrees Celsius, and the temperature is kept for 0.5 to 8 After 30 minutes of stirring, the obtained cosmetic composition was transferred to a specific grinding tool and pressed into shape.

[0081] Table 2

[0082]

[0083]

[0084] The test results are shown in Table 2 above. Compared with Comparative Example 2-3, the powder cake after hydrophobic modification by the method of the present invention in Example 4-5 is softer and more uniform in appearance, full in color, good in smoothness and spreadability, and has ...

Embodiment 6-7

[0085] Example 6-7: Formula and process of emulsified (cream) BB cream containing the powder composition treated by this method

[0086] Prepare according to the formula and order of addition in Table 3, and the specific preparation steps are as follows:

[0087] 1) Add phase A and phase E to the reactor in proportion, and stir at a high speed for 15 minutes; under continuous stirring, the reactor is heated to 60-150 degrees Celsius, and is incubated for 0.5 to 8 hours;

[0088] 2) After cooling to 50 degrees, add phase B to the reactor, stir for 30 minutes, transfer the composition to a three-roll mill and grind it into a slurry;

[0089] 3) The milled color paste is added to the weighed phase C, homogenized for 15 minutes and then included in the D phase in proportion, and stirred at 500 rpm for 15 minutes;

[0090] 4) Filling after cooling to room temperature to obtain a water-in-oil liquid foundation.

[0091] table 3

[0092]

[0093]

[0094] The test results ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com