Preparation process of radiation curing coating, radiation curing coating and application of radiation curing coating

A technology of radiation curing and preparation process, which is applied in the field of building decoration materials, which can solve the problems of reducing product qualification rate and affecting the mirror effect of film pressing process, etc., and achieve the effect of improving product qualification rate, superior coating performance and strong tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

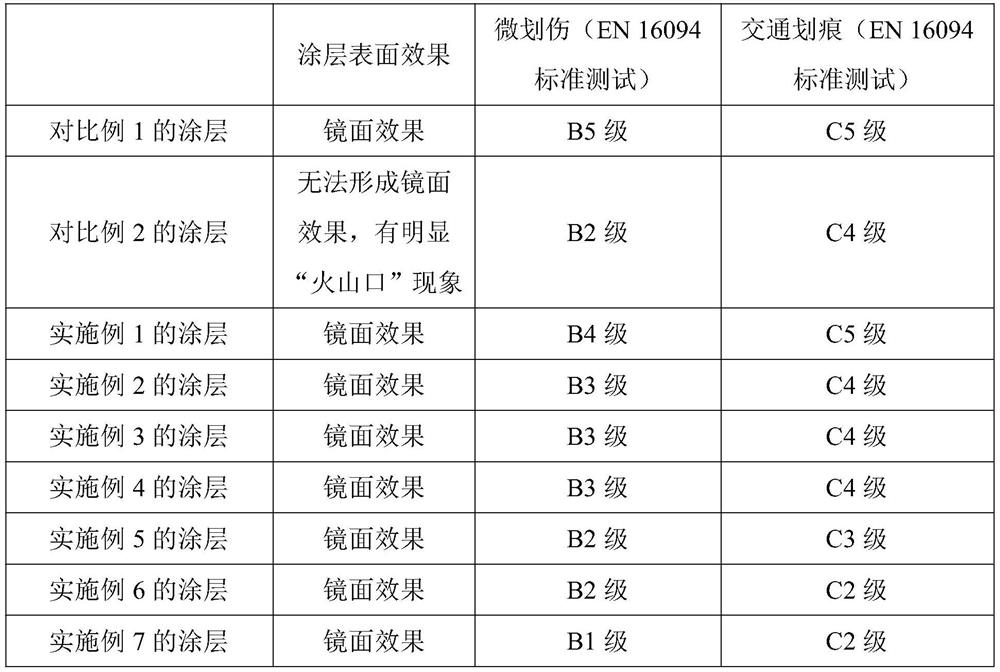

Examples

Embodiment 1

[0042] A preparation process for a radiation-cured coating, comprising the following steps:

[0043] (1) Coating radiation curable coating A on the PET film of 50 μm thickness, PET film is glossy mirror film, and radiation curable coating A comprises the silicon micropowder of 5% (mass content, the same below), and silicon micropowder particle diameter is 2 μm , the coating thickness of coating A is 2g / m 2 , the coating is cured by radiation using a gallium lamp to obtain a pre-coating film;

[0044] (2) Coating radiation-cured coating B on the substrate, radiation-cured coating B is a conventional transparent coating, and the coating thickness is 30g / m 2 , the pre-coating film in step (1) is pasted on the above-mentioned radiation-cured coating B, and the coating surface of the pre-coated film is contacted with the radiation-cured coating B to obtain a coating precursor;

[0045] (3) The coating precursor in step (2) is cured by radiation with a gallium lamp, and after the ...

Embodiment 2

[0050] A preparation process for a radiation-cured coating, comprising the following steps:

[0051] (1) Coating radiation curing coating A on the PET film of 200 μ m thickness, PET film is matte mirror film, and radiation curing coating A comprises 20% glass powder, and glass powder particle size is 20 μ m, and coating A coats Thickness is 10g / m 2 , the coating is cured by radiation using LED lamps to obtain a pre-coating film;

[0052] (2) Coating radiation-cured coating B on the substrate, radiation-cured coating B is a conventional transparent coating, and the coating thickness is 100g / m 2 , the pre-coating film in step (1) is pasted on the above-mentioned radiation-cured coating B, and the coating surface of the pre-coated film is contacted with the radiation-cured coating B to obtain a coating precursor;

[0053] (3) The coating precursor in step (2) is cured by radiation with a gallium lamp, and after the PET film is removed, the coating is cured by a second radiation...

Embodiment 3

[0057] A preparation process for a radiation-cured coating, comprising the following steps:

[0058] (1) Coating radiation-cured coating A on a PET film with a thickness of 100 μm, the PET film is a film with special texture, radiation-cured coating A contains 20% organic-inorganic hybrid nano-modified resin, coating A coating Thickness is 5g / m 2 , using a mercury lamp to cure the coating by radiation to obtain a pre-coated film;

[0059] (2) Coating radiation-cured coating B on the substrate, radiation-cured coating B is a conventional transparent coating, and the coating thickness is 50g / m 2 , the pre-coating film in step (1) is pasted on the above-mentioned radiation-cured coating B, and the coating surface of the pre-coated film is contacted with the radiation-cured coating B to obtain a coating precursor;

[0060] (3) The coating precursor in step (2) is cured by radiation with a gallium lamp, and after the PET film is removed, the coating is cured by a second radiation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com