Preparation method of hydrolysis hydrogen production alloy

A technology for hydrogen production and alloy production by hydrolysis, which is applied in hydrogen production and other directions, can solve problems such as low yield, slow initial rate of hydrogen production, and reduced surface activity of alloys, and achieves a simple method, ensures hydrogen production rate, and improves utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

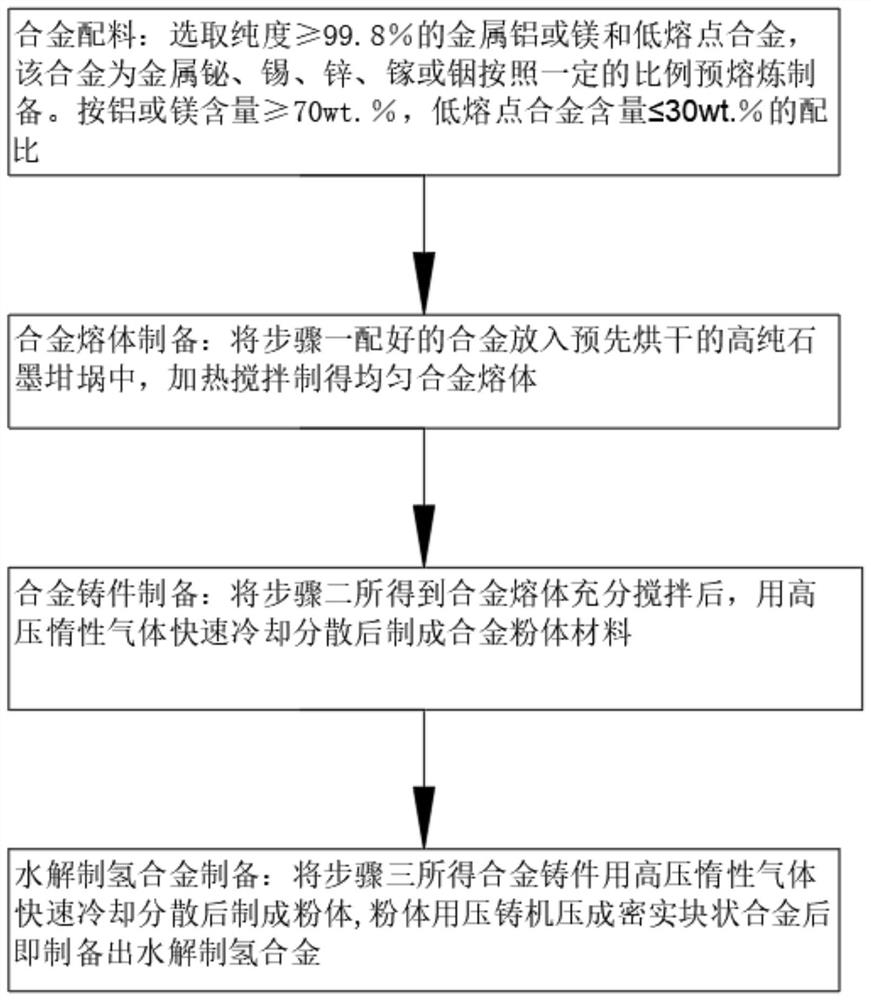

[0032] A preparation method of a hydrolysis hydrogen-producing alloy, comprising the following steps:

[0033] Step 1. Alloy ingredients: select metal aluminum blocks with a purity of ≥99.8% and low melting point metals tin and gallium, according to the ratio of aluminum content of 90wt.%, tin content of 9.5wt.%, and gallium content of 0.5wt.%, The low melting point metals tin and gallium are first melted into a low melting point alloy at a temperature of 250°C;

[0034] Step 2: Preparation of alloy melt: put the processed low-melting point alloy and aluminum in step 1 into a pre-dried high-purity graphite crucible, heat and stir to obtain a uniform alloy melt, and the high-purity graphite crucible is protected in an argon atmosphere Heated to 780°C under low temperature and stirred electromagnetically for 15min to obtain a uniform alloy melt;

[0035]Step 3: Preparation of alloy powder material: The alloy powder material is prepared by rapidly cooling and dispersing the allo...

Embodiment 2

[0038] A preparation method of a hydrolysis hydrogen-producing alloy, comprising the following steps:

[0039] Step 1. Alloy ingredients: select metal magnesium blocks with a purity of ≥99.8% and low melting point metals tin and gallium, according to the ratio of magnesium content of 85wt.%, tin content of 10wt. Metal tin and bismuth are first melted into a low melting point alloy at a temperature of 300 °C;

[0040] Step 2: Preparation of alloy melt: put the low melting point alloy and magnesium processed in step 1 into a pre-dried high-purity graphite crucible, heat and stir to obtain a uniform alloy melt, and the high-purity graphite crucible is protected in an argon atmosphere Heated to 760°C under low temperature and stirred electromagnetically for 12min to obtain a uniform alloy melt;

[0041] Step 3: Preparation of alloy powder material: The alloy powder material is prepared by rapidly cooling and dispersing the alloy melt obtained in step 2 with high-pressure argon ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com