Component, in particular top plate and/or burner cap of gas cooking appliance with non-stick and/or moisture-proof coating, gas cooking appliance comprising such component and method for producing component

A technology of gas burner and burner cap, applied in the direction of copying/marking method, stove/stove bracket/shelf, coating, etc., can solve the problems of high cost, heavy workload, high combustion temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

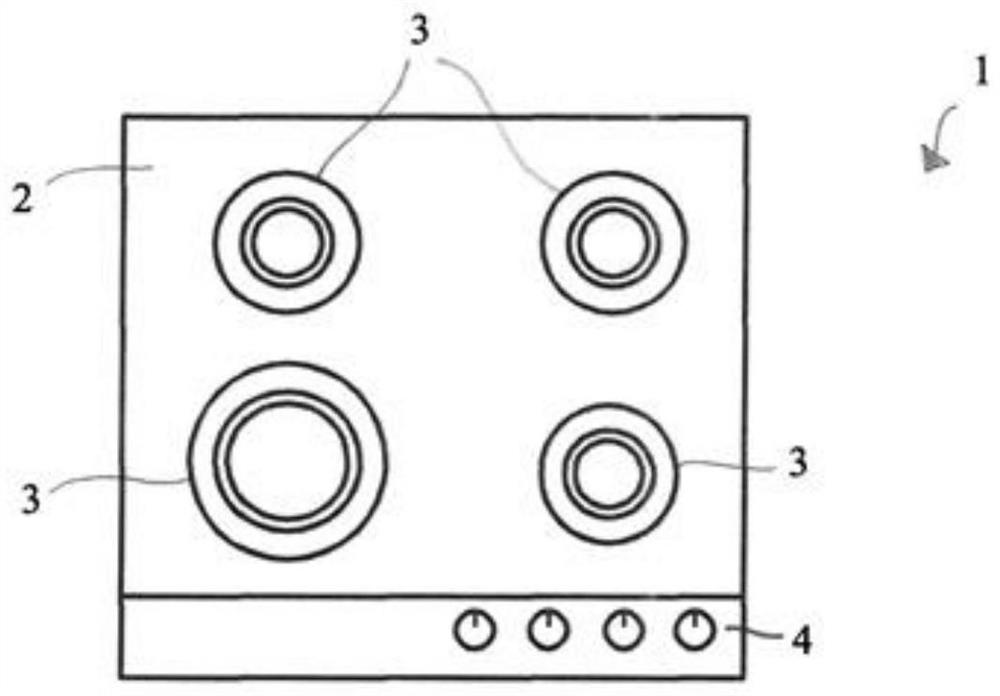

[0084] figure 1 A top view of an embodiment of a gas cooktop 1 is shown. The gas cooktop 1 comprises a part, which is actually a top plate 2 according to the invention, which is plate-like and has an exemplary four cooking zones 3 of different sizes on which the flat bottom for cooking food will be placed pot or pan.

[0085] The gas cooktop 1 further comprises a control panel 4 with several operating and display elements, such as a cooking level display or a setting knob. Additionally, the gas cooktop may include a grate or pot holder (not shown) that may be placed on the top plate 2 .

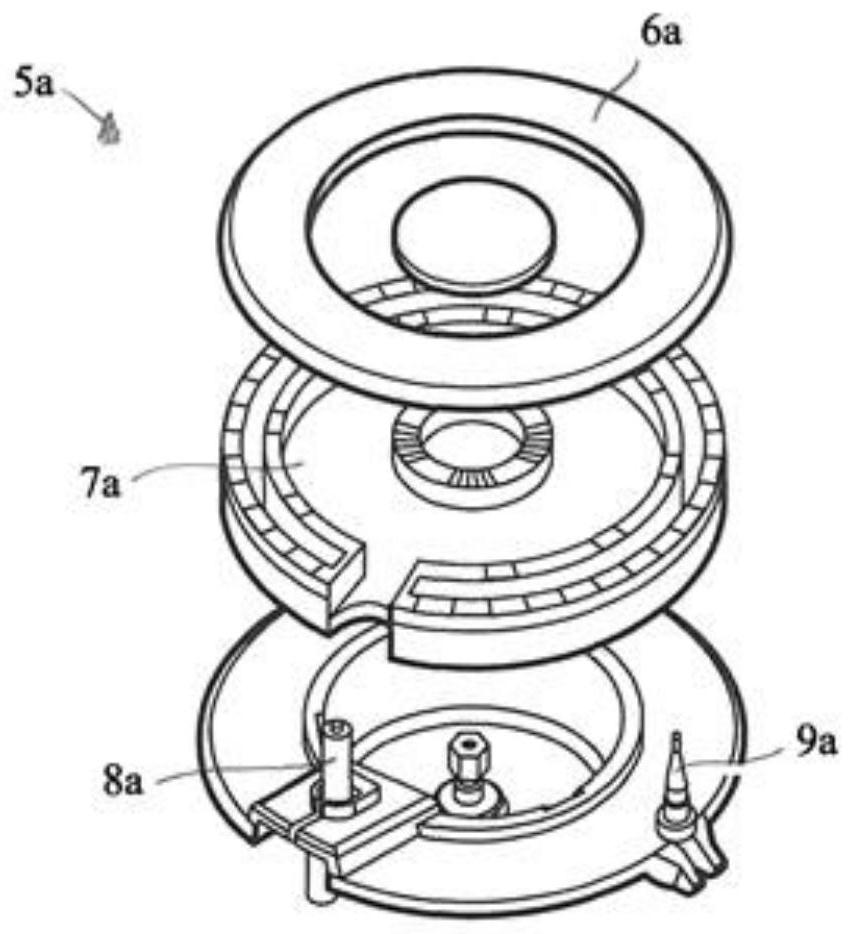

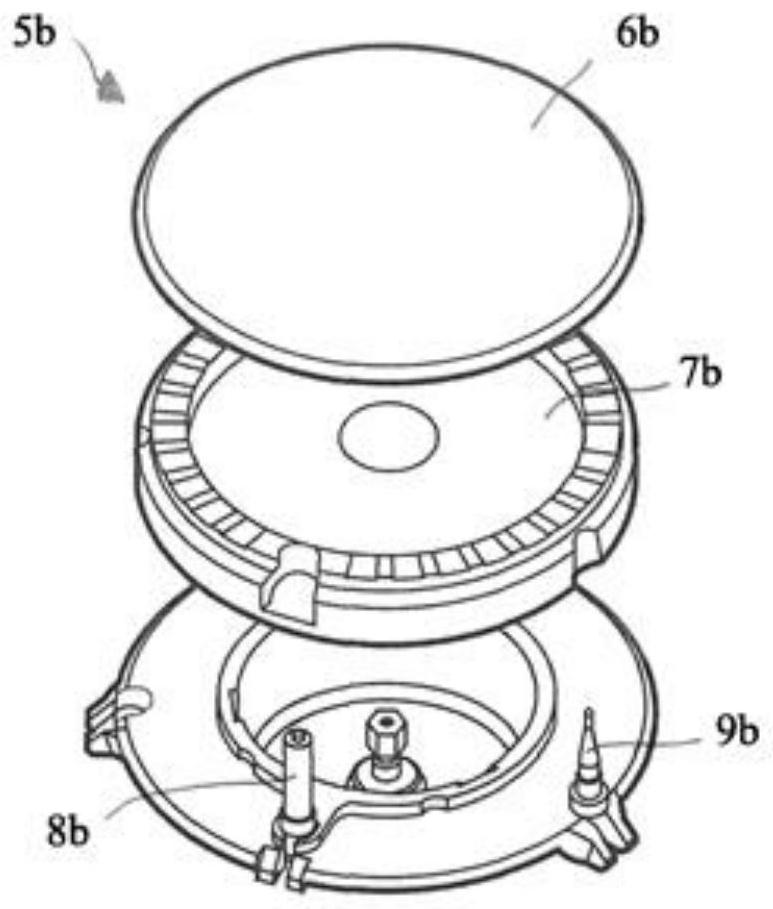

[0086] The gas cooktop 1 further comprises gas burners 5a, 5b for heating the cooking area. Two embodiments of such gas burners 5a, 5b are Figure 2A and Figure 2B shown exemplarily in . The gas burner 5a according to the first embodiment comprises a disc-shaped burner cap 6a, a burner crown 7a, a spark plug 8a and a thermocouple 9a prepared and provided with a non-stick and / or non-wet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com