Coal mine thick and hard sandstone roof water disaster and rock burst composite disaster control method

A technology of rock burst and hard sandstone, which is applied in the field of combined disaster management of thick and hard sandstone roof water damage and rock burst in coal mines. Huge, threatening coal mine safety production and other issues, to achieve the effect of reducing mine water inflow, reducing water crossing sections, and enhancing the value of promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

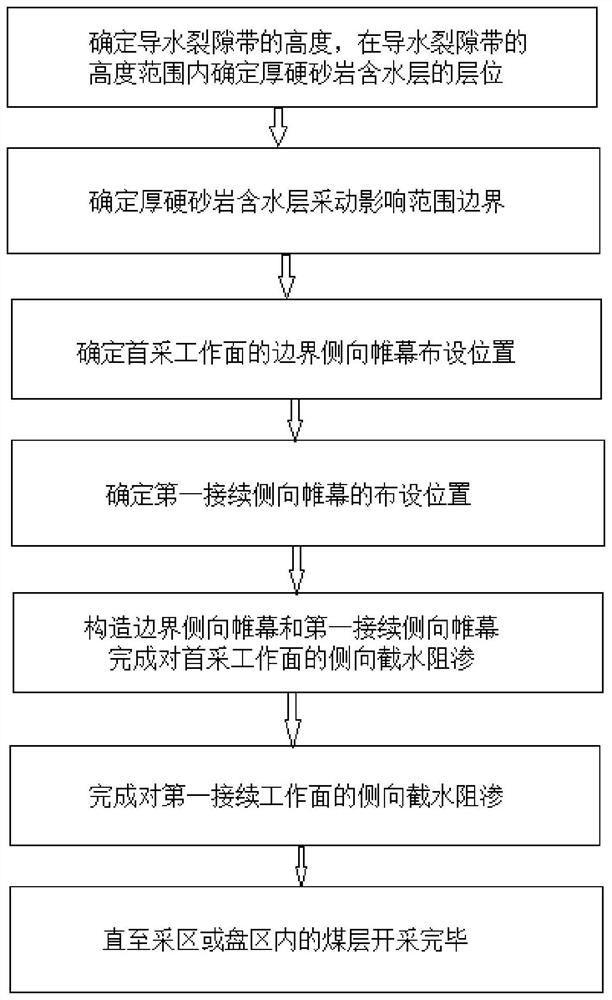

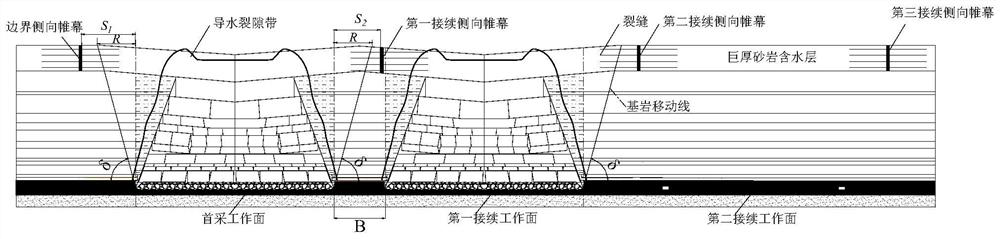

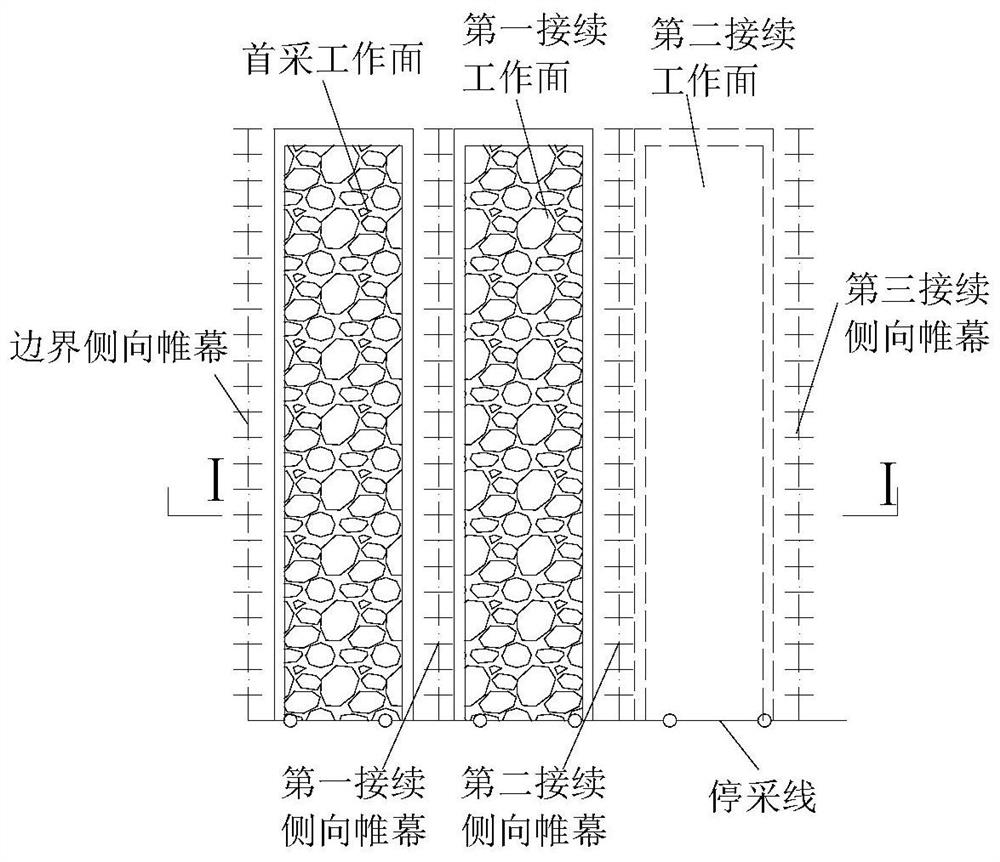

[0052] Follow the above technical solutions, such as Figure 1 to Figure 6 The main coal seam 1 of a coal mine has a thickness of 10m and a burial depth of 680m, which is a near-horizontal coal seam. There is a thick and hard Luohe Formation sandstone aquifer 160m above the coal seam, and a thick and hard sandstone layer occurs on the roof. The lithology of hard sandstone is mainly medium-fine sandstone, fine sandstone and mudstone interbedded. The fully mechanized top-coal mining technology is adopted. It is a ground-bursting mine with complex hydrogeological types.3 / d. The first working face of the mine is 1800m long. The mining plan includes working face 101, working face 102 and working face 103. It is necessary to carry out the combined disaster management of water damage and rock burst on the thick hard sandstone roof of the coal mine.

[0053] The present embodiment provides a method for controlling the composite disaster of water damage and rock burst on the thick and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com