Purification system for wastewater of ceramic industrial production

A waste water purification and ceramic technology, applied in the direction of biological water/sewage treatment, water/sewage treatment, biological treatment devices, etc., can solve the problems of poor biodegradability of waste water, difficult separation of suspended solids, poor treatment effect, etc., to reduce bacteria The effect of breeding, improving the treatment effect and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

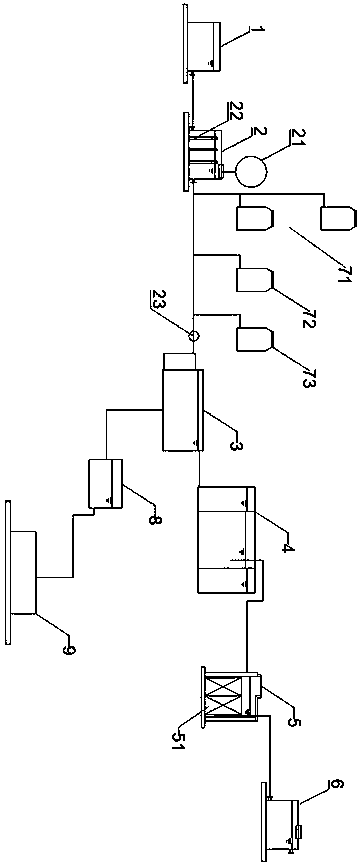

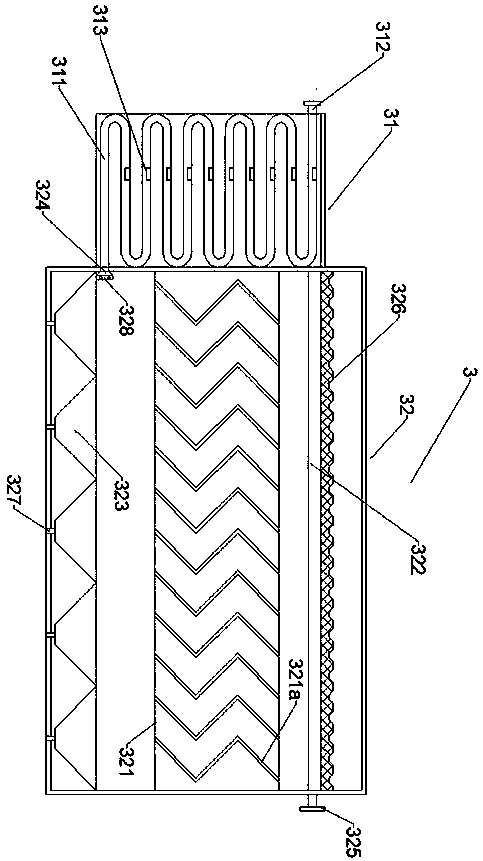

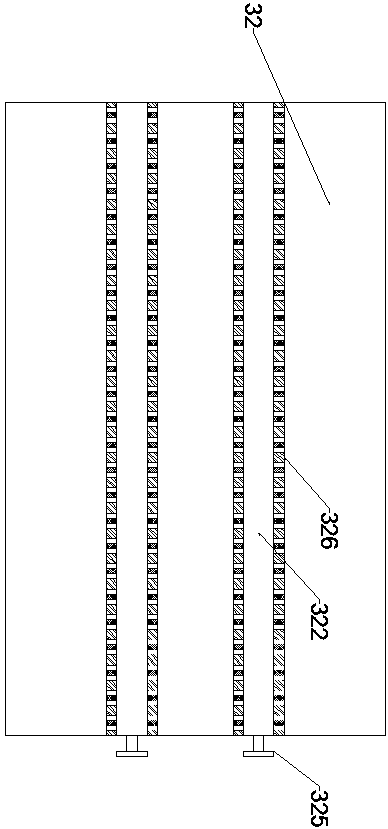

[0031] Such as Figure 1-7 As shown, a wastewater purification system for ceramic industry production, including wastewater storage tank 1, adjustment tank 2, inclined tube sedimentation tank 3, anaerobic-aerobic tank 4, facultative membrane biological reaction tank 5, clear water tank 6, six connected by pipes. At the same time, the inclined tube sedimentation tank 3 is connected with the sludge thickening tank 8 and the sludge filter press device 9 in turn through pipelines.

[0032] The setting of the adjustment tank 2 is to make the waste water quality uniform and stable, avoid large fluctuations in water quality, and improve the impact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com