Hot melting piece, nail gun clamp for fixing hot melting piece and fixing method of hot melting piece

A hot-melt sheet and nail gun technology, applied in nailing tools, nail staple tools, manufacturing tools, etc., can solve the problems of not easy to operate the nail gun, easy to hit the hand, broken hot-melt sheet, etc., to achieve the structure Simple, easy to install, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

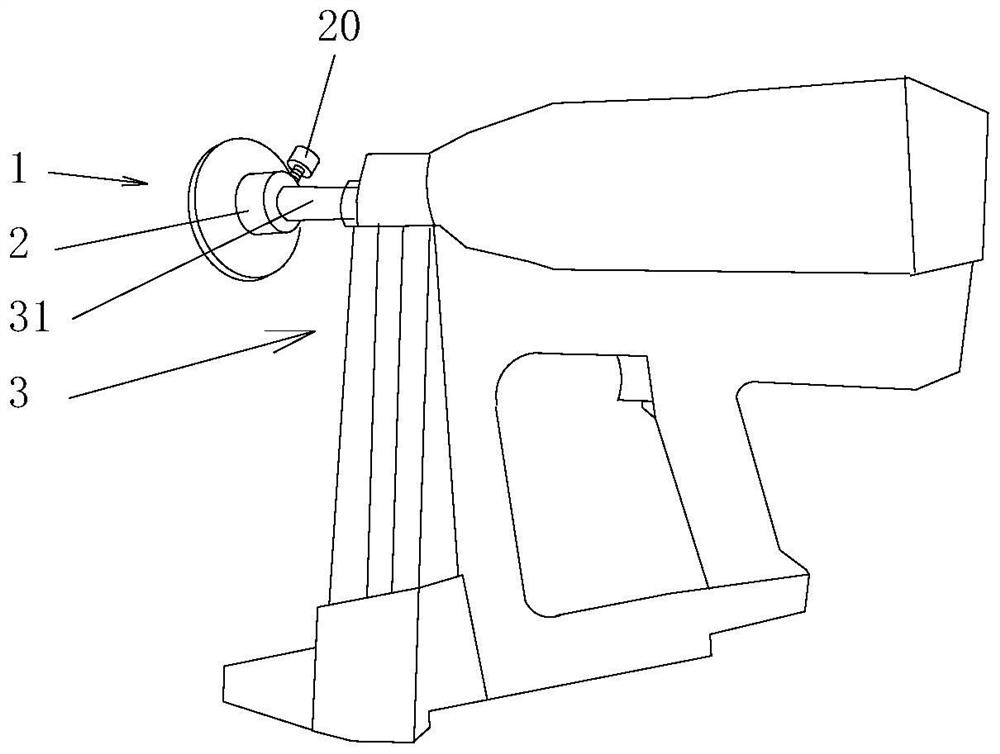

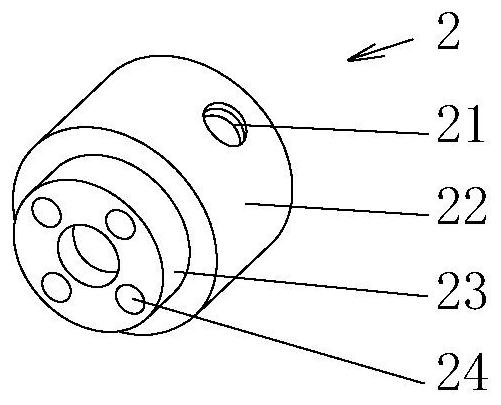

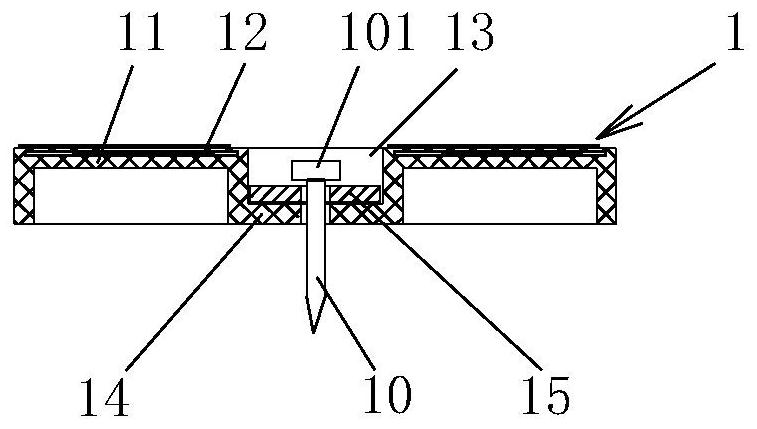

[0031] Example: as figure 1 As shown, a hot-melt sheet includes a hot-melt sheet body, a metal mesh 12 for electromagnetic heating is fixed on the top surface of a plastic sheet 11 of the hot-melt sheet body, and an inner groove 13 is provided in the middle of the plastic sheet 11. The inner concave surface 14 of the slot 13 is provided with a nail hole, a magnetic conductive material sheet 15 is fixed on the inner concave surface 14, and a through hole is opened in the center of the magnetic conductive material sheet 15, and the nail 10 can pass through the through hole and the inner concave surface of the magnetic conductive material sheet 15. The nail holes of 14 are inserted into the building, the nail heads 101 of the nails 10 can press the magnetic conductive material sheet 15 so that the plastic sheet 11 can be fixed on the building, and the nail heads 101 sink into the inner grooves 13 .

[0032] The magnetic conductive material sheet 15 provided in the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com