Method for removing ultra-deep cold stress of aluminum alloy

An aluminum alloy and stress technology, which is applied in the field of aluminum alloy processing, can solve the problems of low residual stress removal rate of aluminum alloy parts, unsatisfactory users, unsatisfactory realization effect, etc., and achieve the effect of improving quality and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

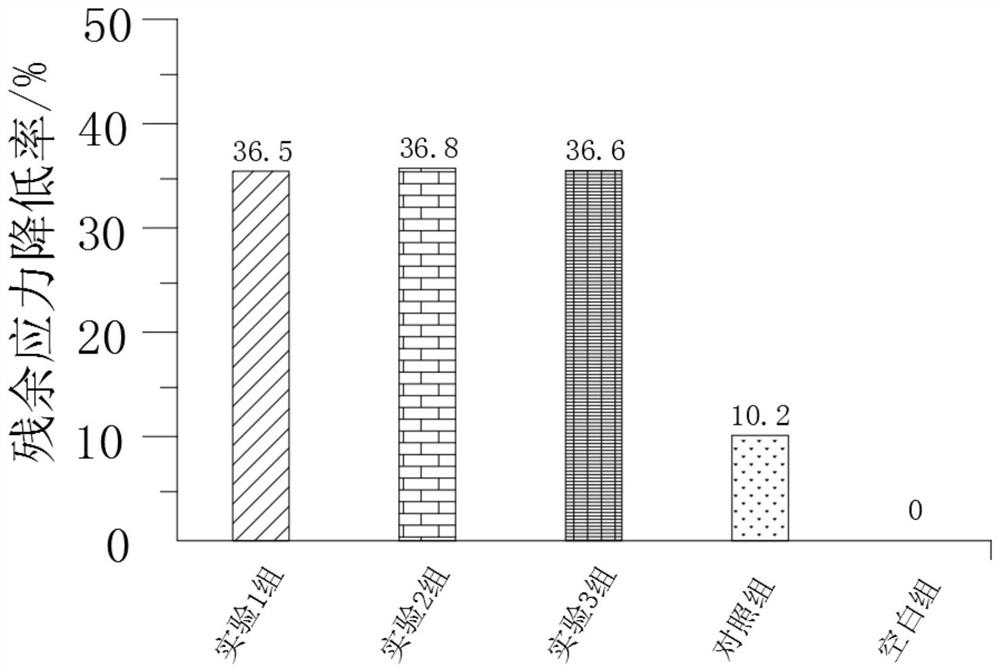

Examples

Embodiment 1

[0027] The invention provides a method for removing ultra-cryogenic stress of aluminum alloy, comprising the following steps:

[0028] (1) Take the aluminum alloy parts containing residual stress, and place the aluminum alloy parts in a heating furnace for heating and heat preservation.

[0029] Further, placing the aluminum alloy part in a heating furnace for heating and heat preservation treatment is to heat the aluminum alloy part to 360° C., hold the temperature for 10 minutes, and then heat it to 500° C. for 20 minutes.

[0030] (2) Quenching the aluminum alloy piece treated in step (1) into still water for water quenching treatment.

[0031] Further, the temperature of the still water was 25°C.

[0032] (3) The aluminum alloy parts after water quenching are cooled twice with liquid nitrogen.

[0033] Further, the two cooling with liquid nitrogen is to first use liquid nitrogen at -90°C to cool the aluminum alloy parts for 20 minutes, and then use liquid nitrogen at -19...

Embodiment 2

[0042] The invention provides a method for removing ultra-cryogenic stress of aluminum alloy, comprising the following steps:

[0043] (1) Take the aluminum alloy parts containing residual stress, and place the aluminum alloy parts in a heating furnace for heating and heat preservation.

[0044] Further, placing the aluminum alloy part in a heating furnace for heating and heat preservation treatment is to heat the aluminum alloy part to 360° C., hold the temperature for 15 minutes, and then heat it to 500° C. and hold the temperature for 25 minutes.

[0045] (2) Quenching the aluminum alloy piece treated in step (1) into still water for water quenching treatment.

[0046] Further, the temperature of the still water was 25°C.

[0047] (3) The aluminum alloy parts after water quenching are cooled twice with liquid nitrogen.

[0048] Further, two cooling with liquid nitrogen is to first use -90 ℃ liquid nitrogen to cool the aluminum alloy parts for 25 minutes, and then use -196...

Embodiment 3

[0057] The invention provides a method for removing ultra-cryogenic stress of aluminum alloy, comprising the following steps:

[0058] (1) Take the aluminum alloy parts containing residual stress, and place the aluminum alloy parts in a heating furnace for heating and heat preservation.

[0059] Further, placing the aluminum alloy parts in a heating furnace for heating and heat preservation treatment is to heat the aluminum alloy parts to 360° C., hold the temperature for 20 minutes, and then heat the aluminum alloy parts to 500° C. for 30 minutes.

[0060] (2) Quenching the aluminum alloy piece treated in step (1) into still water for water quenching treatment.

[0061] Further, the temperature of the still water was 25°C.

[0062] (3) The aluminum alloy parts after water quenching are cooled twice with liquid nitrogen.

[0063] Further, two cooling with liquid nitrogen is to first use -90 ℃ liquid nitrogen to cool the aluminum alloy parts for 30 minutes, and then use -196 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com