Stretching equipment for polymer composite multilayer material

A technology of multi-layer materials and stretching equipment, applied in the direction of coating, etc., can solve the problems of inability to guarantee whether the stretching is in place, material damage, unsuitable for online detection of film stretching production lines, etc., to avoid deterioration of mechanical properties, The effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] (1) Structure of tensile equipment

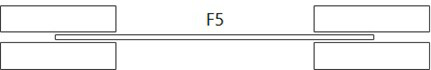

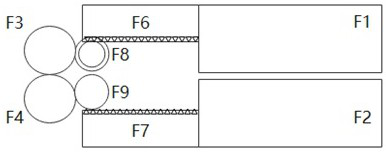

[0030] The stretching equipment includes an upper clamping and fixing device F1 and a lower clamping and fixing device F2, which are used to clamp the base film F5 to be stretched. The upper clamping fixture and the lower clamping fixture appear in pairs, forming a clamping fixture pair. The pair of clamping and fixing devices can be arranged on both sides of the base film in the length direction or on both sides in the width direction, and of course can also be arranged at other positions that need to be stretched. The corresponding position can be set according to the specific use of the stretching equipment.

[0031] An upper driving device F6 is fixed on the outer side of the upper clamping and fixing device, and a lower driving device F7 is fixed on the outer side of the lower clamping and fixing device. The lower surface of the upper driving device F6 is a rack structure, and the upper surface of the lower driving device F7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com